Mixed fertilizer for targeted matching of nitrogen requirements for rice and application

A technology of mixed fertilizer and rice, applied in the direction of urea compound fertilizer, application, nitrogen fertilizer, etc., can solve the problems of inaccurate synchronization of "double peak" nitrogen absorption law, etc., achieve high production cost, reduce main nitrogen loss, and mix ratio Manipulate complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

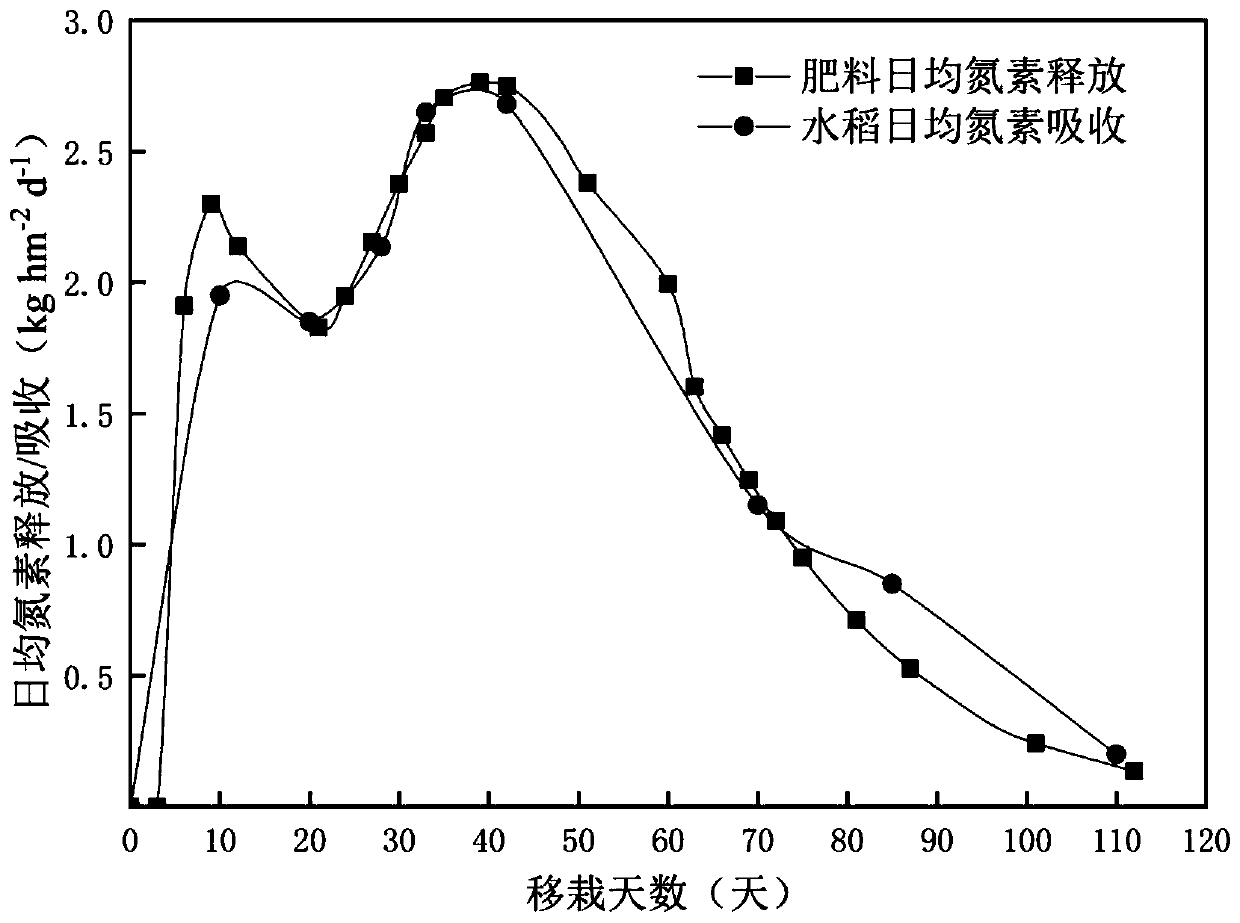

[0026] The applicant conducted a field test with the mixed fertilizer of the present invention at the Lujiang Experimental Base of Anhui Agricultural University (31°48'N, 117°23'E) in 2019, using conventional urea artificially applied multiple times and no nitrogen fertilizer as a control example.

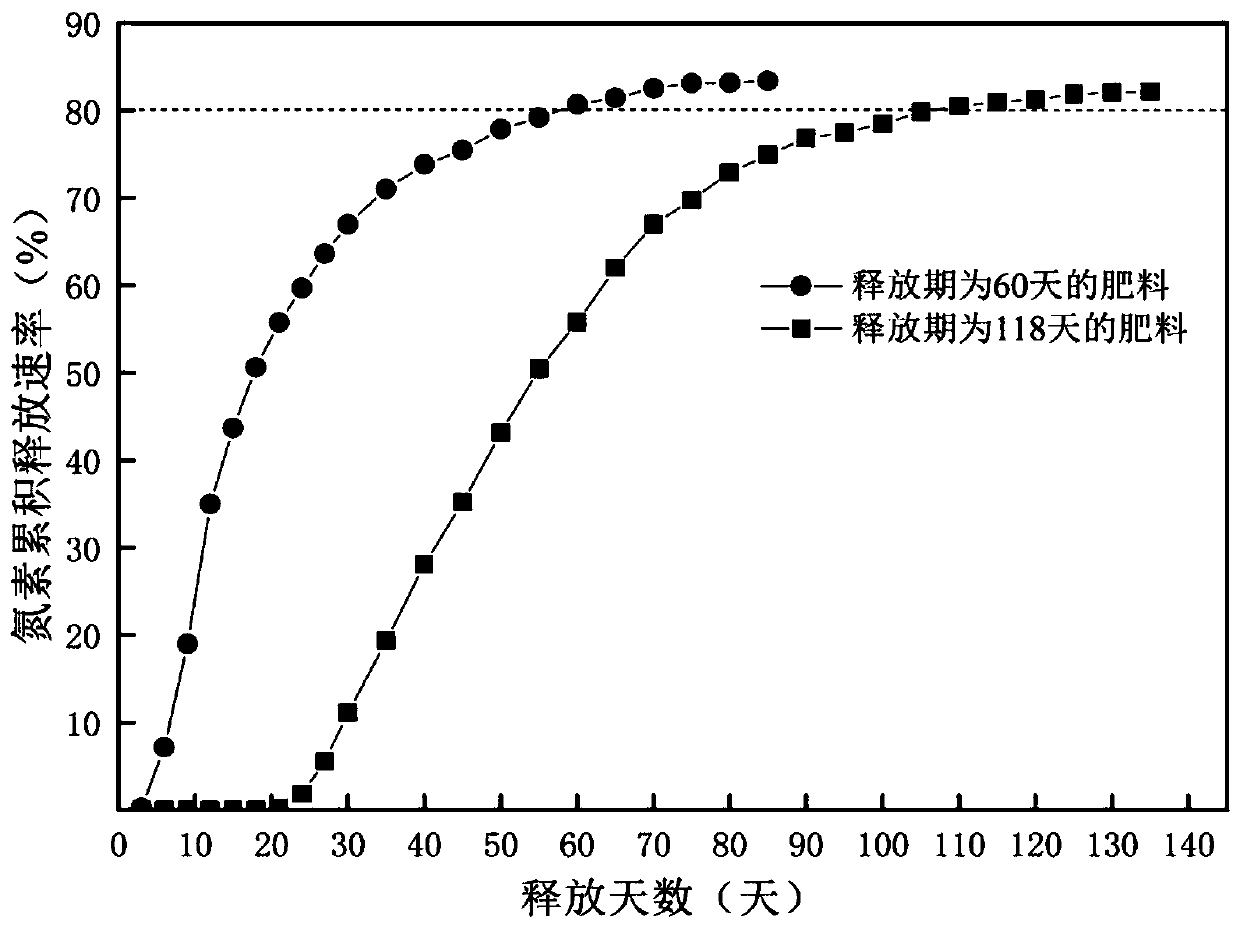

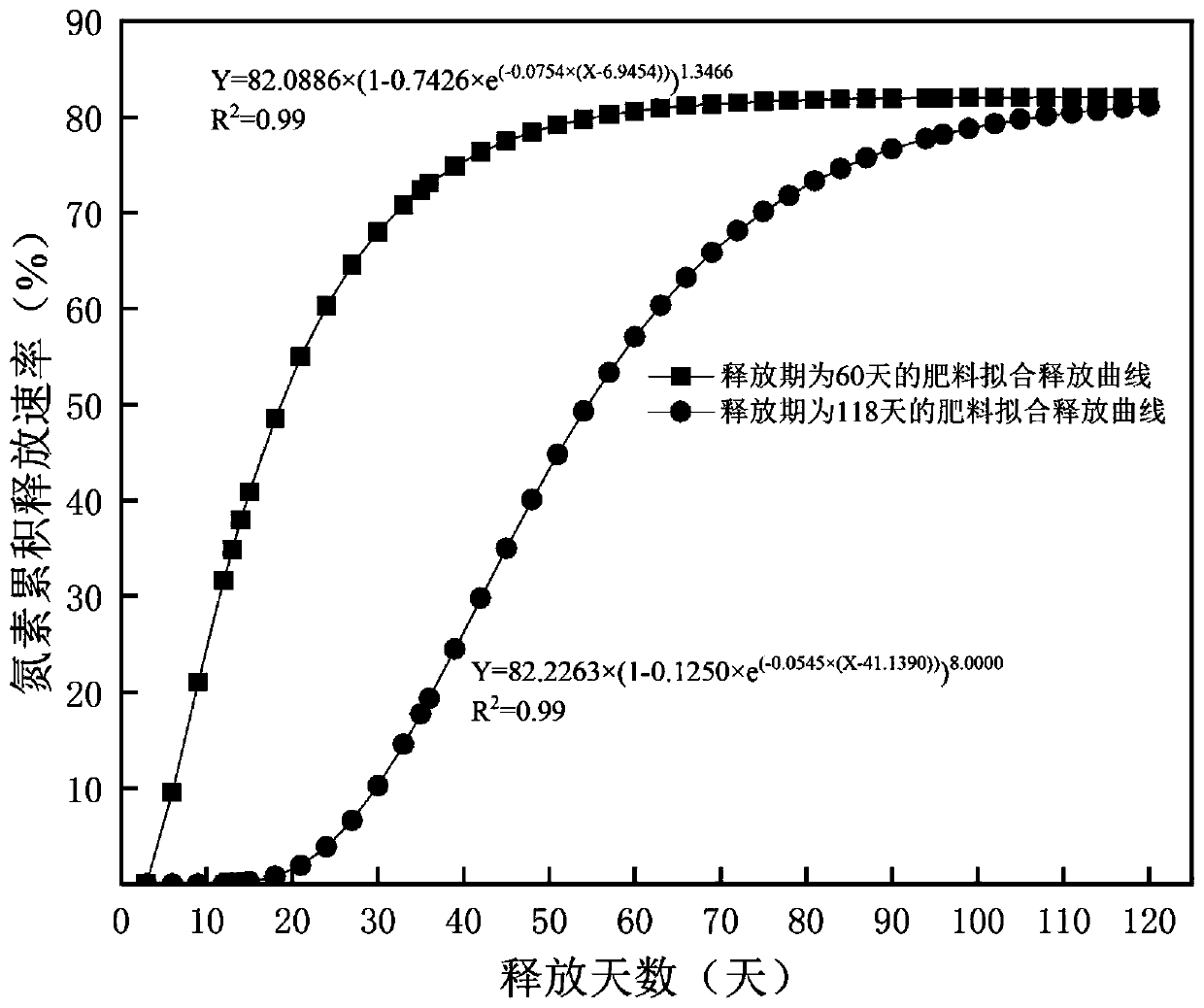

[0027] (1) Preparation of rice mixed fertilizer targeted to match nitrogen demand

[0028] The first vegetable oil-based polyurethane-coated urea and the second vegetable oil-based polyurethane-coated urea are prepared according to the mass ratio of 3:7, and the mass ratio of the coating material of the first vegetable oil-based polyurethane-coated urea to the core urea is: 2.5%, the mass ratio of the coating material of the second vegetable oil-based polyurethane coated urea to the core urea is 3.2%, and the nitrogen mass percentage in the rice mixed fertilizer targeted to match the nitrogen demand is 41%, The raw materials for the production of vegetable oil-based polyurethane co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com