A kind of aluminum-clad strip and its manufacturing method

A manufacturing method and technology of aluminum-clad sheet, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of poor steel-aluminum bonding strength, extremely high P content requirements, and difficult production of aluminum-clad sheet strips, etc., to achieve good corrosion resistance, Excellent comprehensive mechanical properties and excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

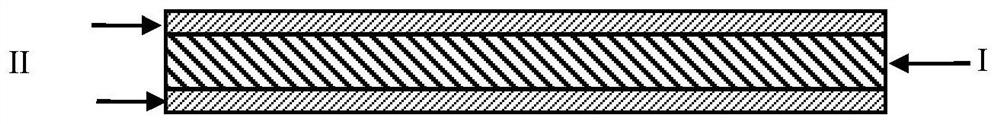

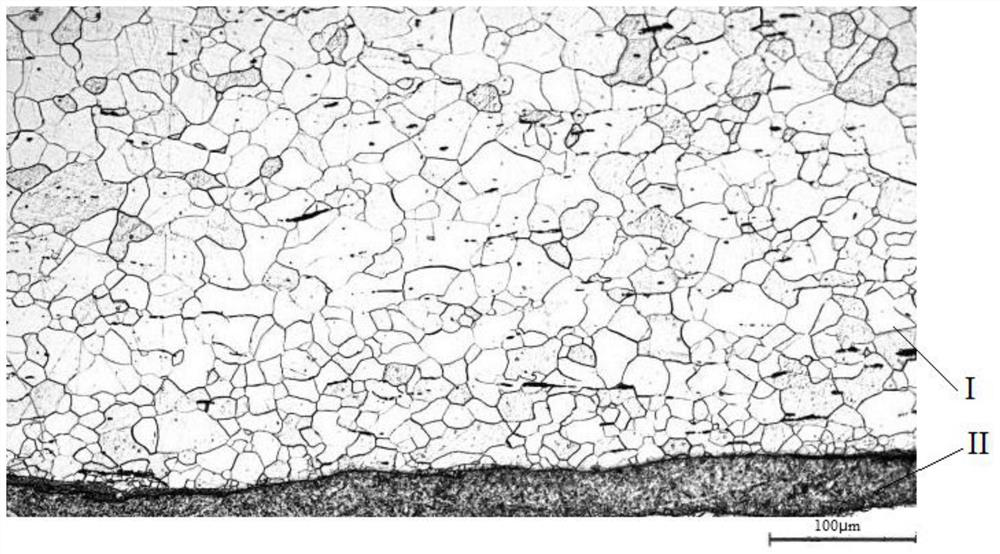

[0055] Examples 1-15 The aluminum substrate includes a steel substrate and an aluminum layer covering the surface of the steel substrate, wherein the coated aluminum strip of Example 1-8 employs 0.2 mm aluminum strip as an aluminum layer in a steel substrate. On (see figure 1 ) image 3 ), The mass percent of each of the chemical elements of the steel substrates, as shown in Table 1.

[0056] Table 1 lists the mass percentage (wt%) of each of the chemical elements in the steel substrate of the aluminum substrate in Examples 1-15.

[0057] Table 1. (wt%, margin is Fe and other inevitable impurity elements other than s)

[0058]

[0059] The method for producing an aluminum plate strip of Examples 1-15 is made of the following steps:

[0060] (1) The steel strip is obtained according to the steel substrate component listed in Table 1 and 0.2 mm aluminum layer as an aluminum strip.

[0061] (2) Surface treatment of the steel strip and aluminum belt.

[0062] (3) Aluminum is covered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com