Low-cost coal and gas co-mining system

A low-cost and gas-friendly technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problem of high production cost, shorten the extraction cycle, shorten the mining connection cycle, and have broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

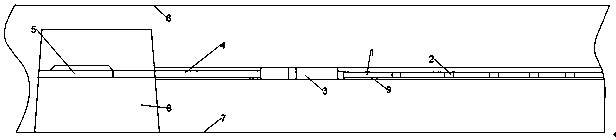

[0020] A low-cost coal and gas co-production system, including a cracker 1 and a hole sealing device 3, the number of the crackers 1 is multiple and the crackers 1 are all fixed in the borehole 9, and multiple crackers 1 The hole-sealing device 3 is connected with the cracker 1 in order to seal the borehole 9. One end of the hole-sealing device 3 is connected with a lead-out rod 4, and the lead-out rod 4 is fixed with a starting bus connected to the pressure pipeline. Install this product between the bottom plate 7 and the top plate 8, test the pressure pipeline in the drill hole 9 and lead out the starting busbar, push the lead-out rod 4 to lead out the start-up busbar, when the lead-out rod 4 is pushed into the designed sealing depth, No longer advance the lead-out rod 4 to ensure that the resistance of the starting bus bar is stable, connect the pressure pipeline with the water injection pressure pump, pressurize the hole sealing device 3 in the borehole 9, and when the pres...

Embodiment 2

[0026] A low-cost coal and gas co-production system, including a cracker 1 and a hole sealing device 3, the number of the crackers 1 is multiple and the crackers 1 are all fixed in the borehole 9, and multiple crackers 1 The hole-sealing device 3 is connected with the cracker 1 in order to seal the borehole 9. One end of the hole-sealing device 3 is connected with a lead-out rod 4, and the lead-out rod 4 is fixed with a starting bus connected to the pressure pipeline. Install this product between the bottom plate 7 and the top plate 8, test the pressure pipeline in the drill hole 9 and lead out the starting busbar, push the lead-out rod 4 to lead out the start-up busbar, when the lead-out rod 4 is pushed into the designed sealing depth, No longer advance the lead-out rod 4 to ensure that the resistance of the starting bus bar is stable, connect the pressure pipeline with the water injection pressure pump, pressurize the hole sealing device 3 in the borehole 9, and when the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com