High-efficiency energy-saving spraying fan for textile air conditioner and operating method thereof

A spray fan and high-efficiency technology, applied in the field of high-efficiency energy-saving spray fans, can solve the problems of large equipment, waste of water resources, energy consumption, etc., and achieve the effect of increasing the heat and moisture exchange area, saving electricity and water energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

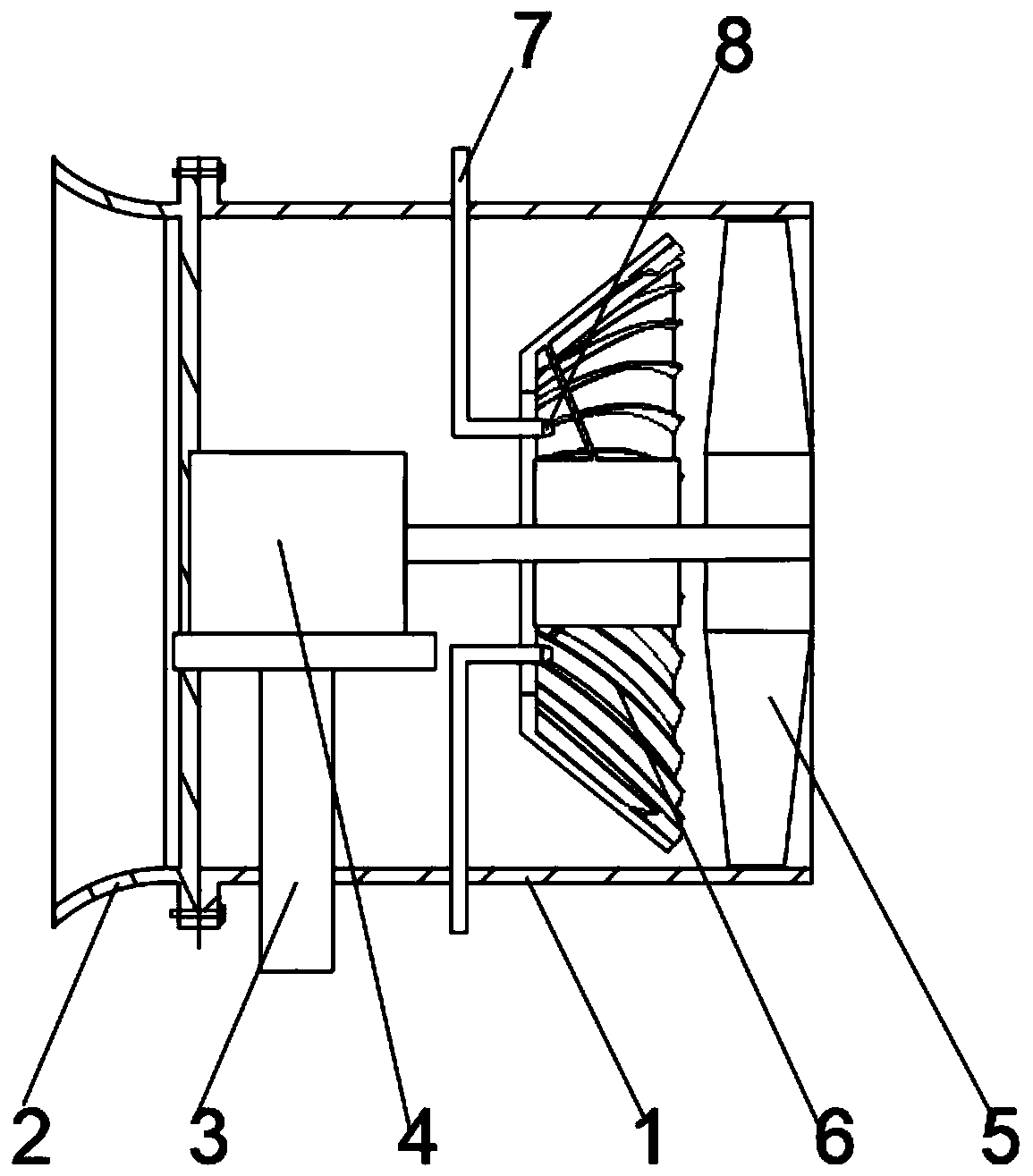

[0027] Such as figure 1 The high-efficiency energy-saving spray fan for textile air conditioning shown includes a main cylinder body 1, an air collector 2 fixedly connected to one end of the main cylinder body 1, a motor 4 fixed to one end of the main cylinder body 1 through a motor bracket 3, The impeller 5 fixed to the motor shaft, the water distribution tray 6, the water supply pipe 7 and the nozzle 8 fixedly installed on the end of the water supply pipe 7, the water distribution tray 6 is fixed to the motor shaft, and is located between the motor 4 and the impeller 5, the The water supply pipe 7 extends through the main cylinder 1 to the side of the water diffuser 6 away from the impeller 5, and the water diffuser 6 disperses the water sprayed by the nozzle 8 under the discrete action generated by the high-speed rotation.

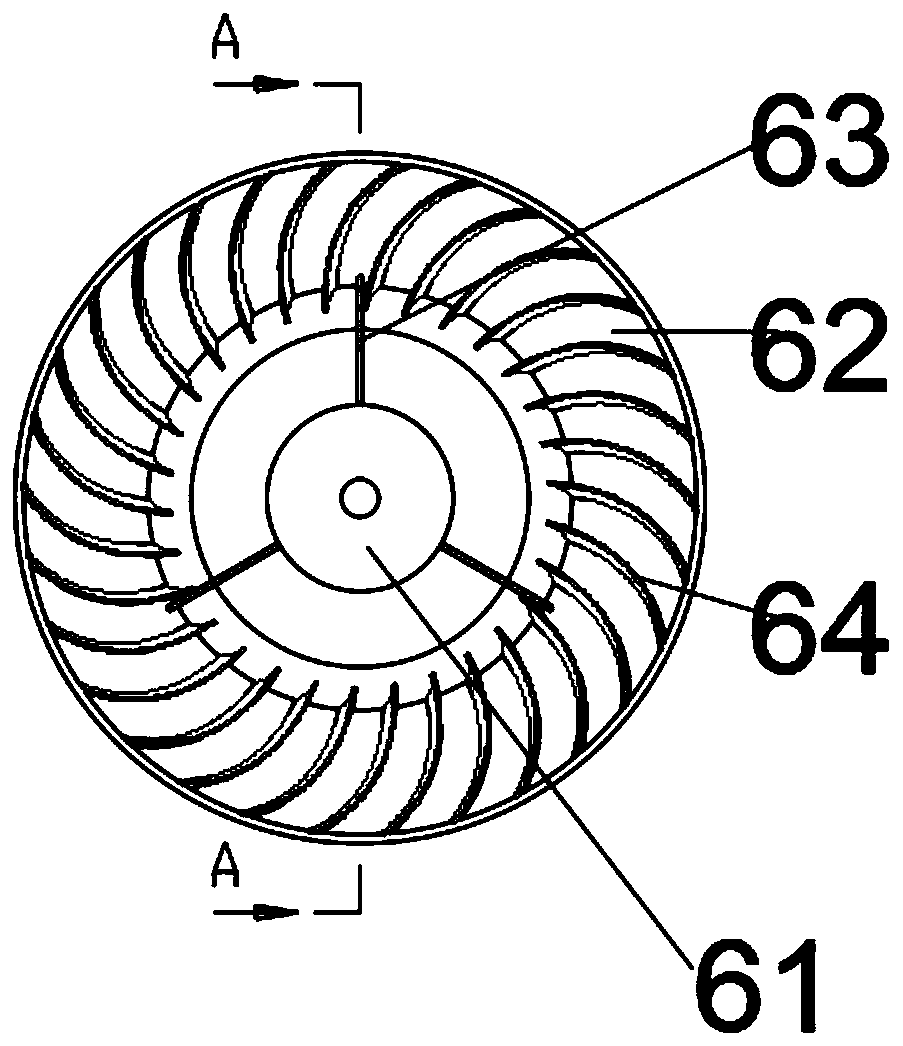

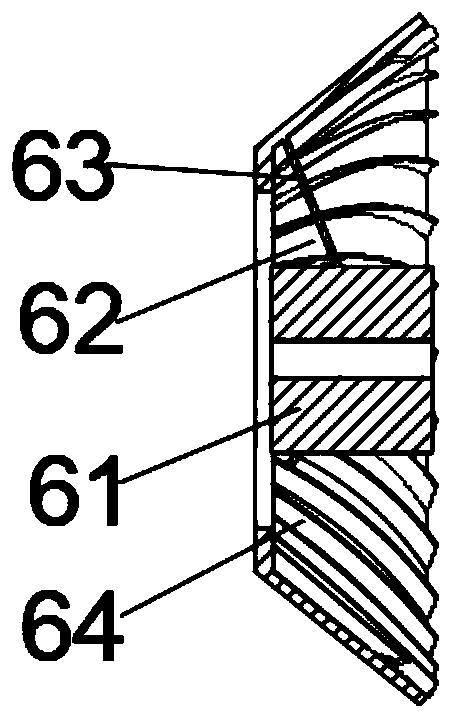

[0028] Further, such as figure 2 with image 3 As shown, the above-mentioned high-efficiency energy-saving spray fan for textile air conditioning, t...

Embodiment 2

[0034] Such as Figure 4 The high-efficiency energy-saving spray fan for textile air conditioning shown includes a main cylinder body 1, an air collector 2 fixedly connected to one end of the main cylinder body 1, a motor 4 fixed to one end of the main cylinder body 1 through a motor bracket 3, The impeller 5 fixed to the motor shaft, the water distribution tray 6, the water supply pipe 7 and the nozzle 8 fixedly installed on the end of the water supply pipe 7, the water distribution tray 6 is fixed to the motor shaft, and is located between the motor 4 and the impeller 5, the The water supply pipe 7 extends through the main cylinder 1 to the side of the water diffuser 6 away from the impeller 5, and the water diffuser 6 disperses the water sprayed by the nozzle 8 under the discrete action generated by the high-speed rotation.

[0035] Further, such as figure 2 with image 3 As shown, the above-mentioned high-efficiency energy-saving spray fan for textile air conditioning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com