Compact type steam generator secondary-side tube plate drying device

A technology of steam generator and drying device, which is applied in drying, drying machine, drying gas arrangement, etc., which can solve the problems of easy fire, contamination risk, and large volume of equipment, and achieve high equipment reliability and eliminate Fire risk, effect of structural firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

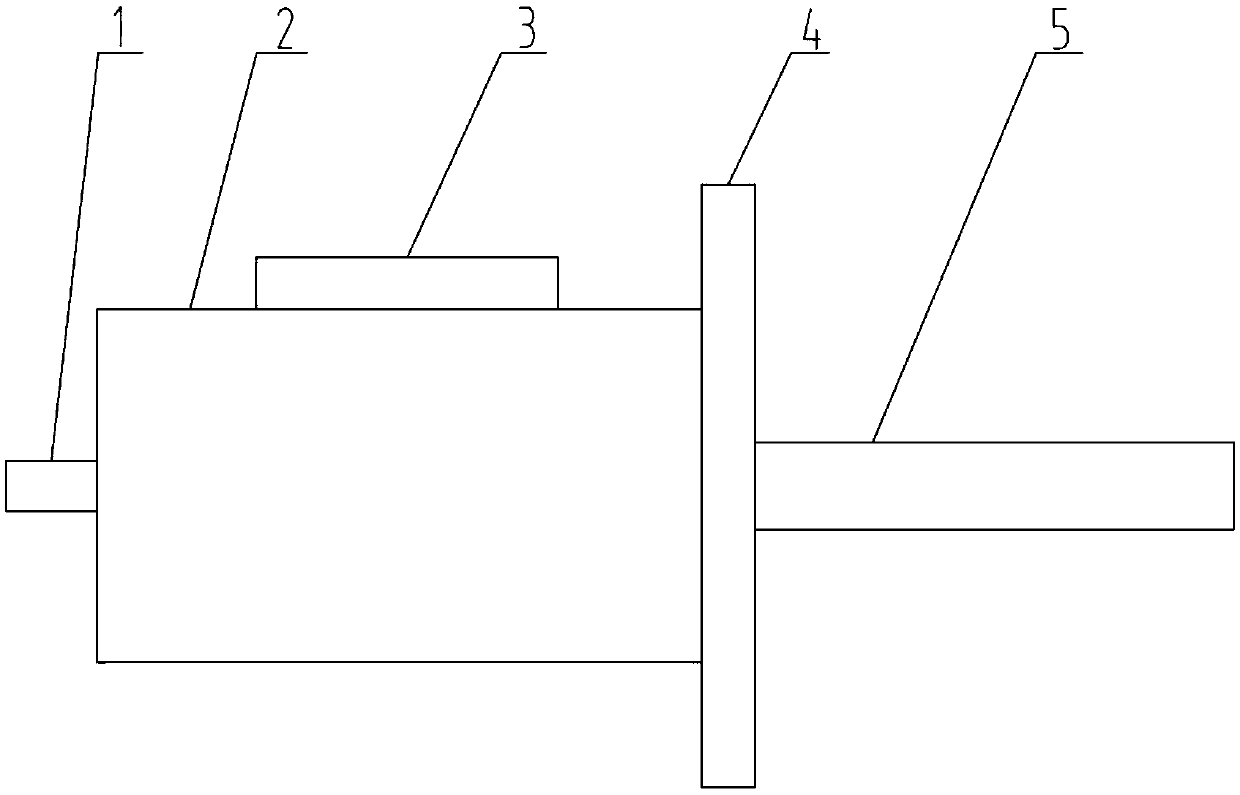

[0028] This embodiment provides a compact steam generator secondary side tube sheet drying device 6, the structure of which is as follows figure 1 As shown, it includes a gas source connector 1, a heating and gas distribution component 2, a control component 3, a mounting flange 4 and an air induction nozzle 5.

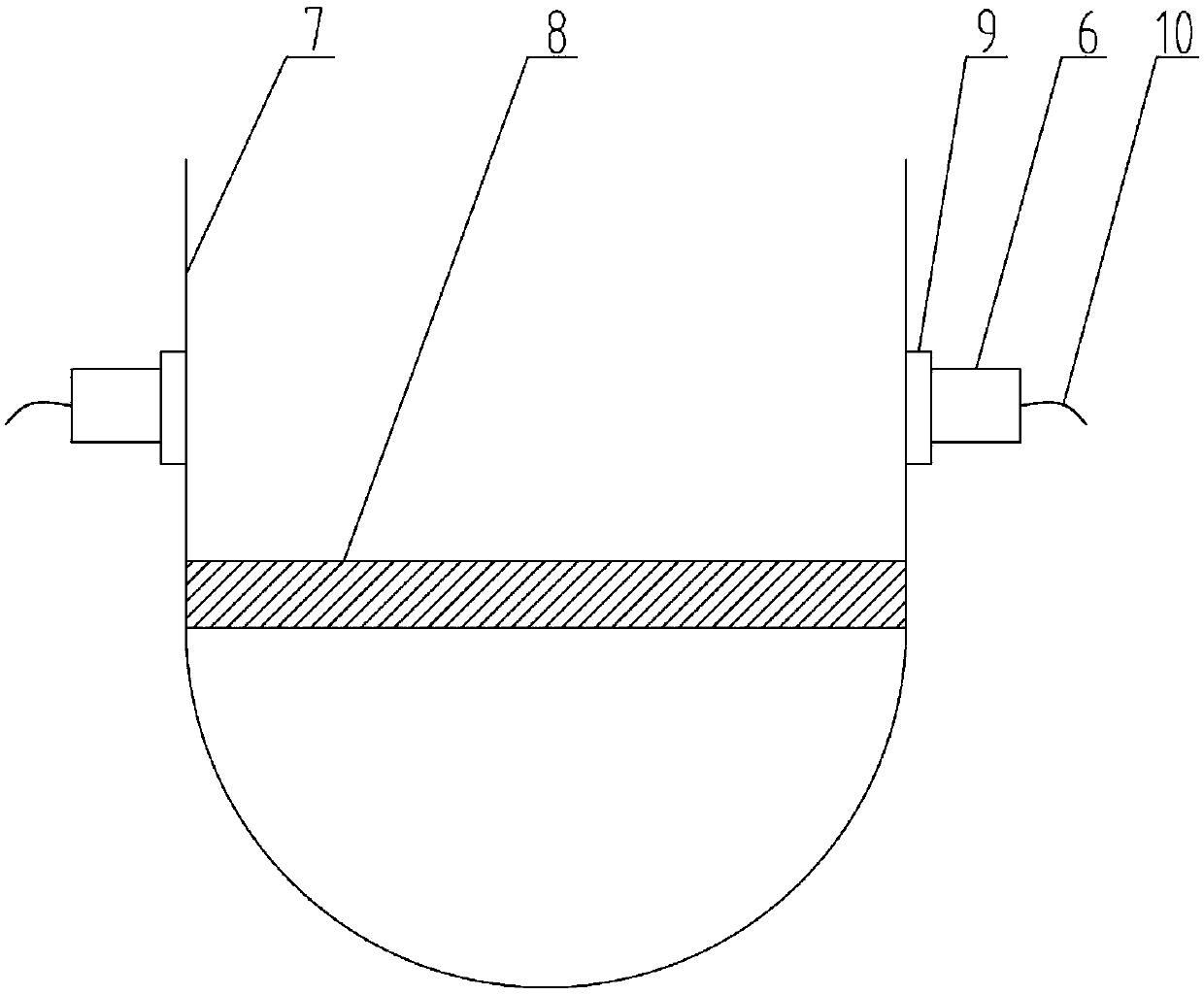

[0029] The drying device 6 of this embodiment is connected to the compressed air system in the nuclear island through the air source connector 1, and uses the compressed air of the nuclear island system such as the public compressed air distribution system SAT as the input air source. Such as figure 2 As shown, the air pipe 10 connected to the compressed air system in the island is firmly connected with the air source joint 1 in the form of a push-in joint, so as to provide a stable and clean air source for the drying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com