Automatic control system of bundling machine

An automatic control system, control system technology, applied in the direction of general control system, control/regulation system, computer control, etc., can solve the problems of poor work efficiency, difficult control of oil pressure, suffocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

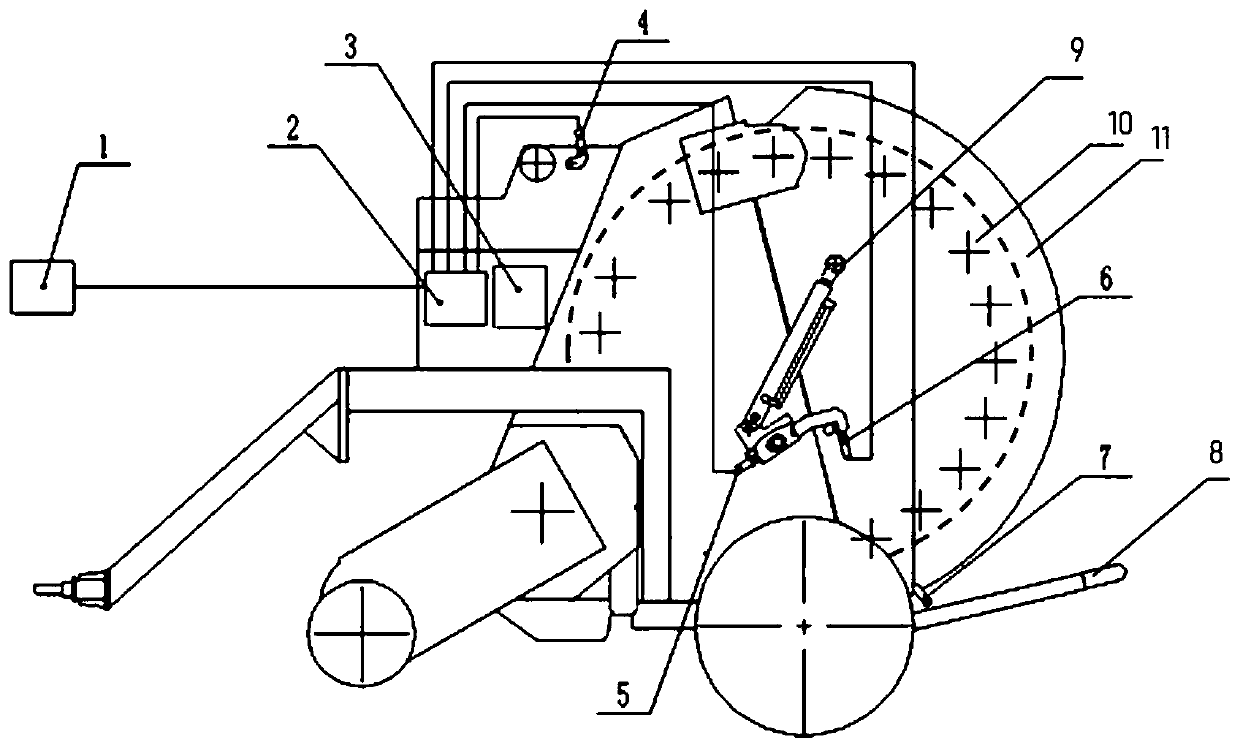

[0022] The automatic control system of the baler of the invention is applied to the operation control of the baler, including a feeding control system, a compression control system, a net release control system, an unloading control system, a microprocessor 2 and a display device 1;

[0023] Feed control system:

[0024] The task of the feeding control system is to control the walking speed according to the change of the feeding amount, so that the feeding amount is stabilized within the rated range. The entire feeding control system is divided into three modules: signal acquisition module, including pressure sensor and speed sensor; single-chip microcomputer module; hydraulic drive module, including walking continuously variable transmission, solenoid valve, hydraulic cylinder.

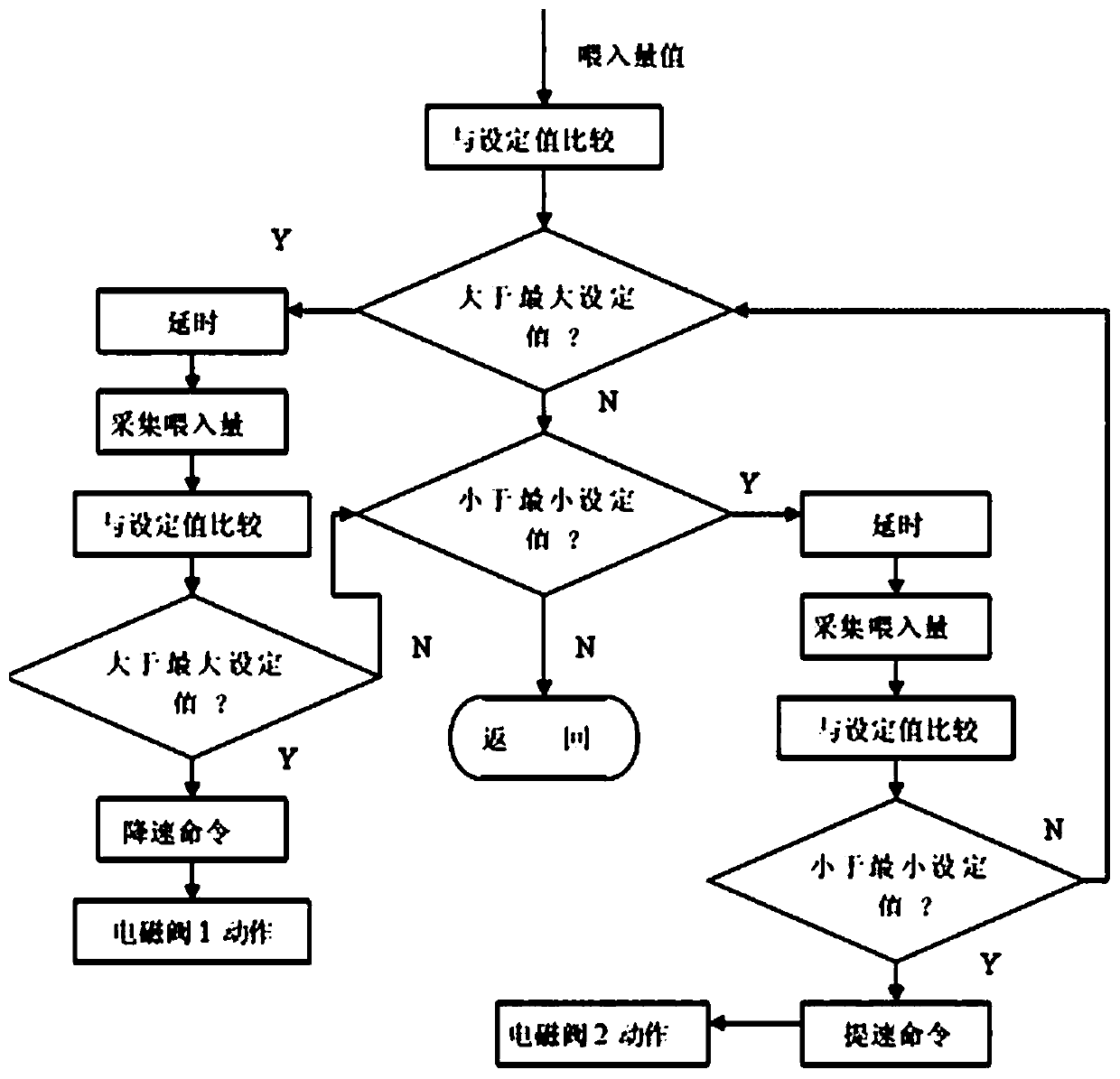

[0025] Reference attached figure 1 , the signal acquisition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com