Electrolyte membrane, its production equipment and preparation process

An electrolyte membrane and production equipment technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing, etc., can solve the problems of low energy storage, slow charging and discharging speed, short service life, etc. The effect of storing energy and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

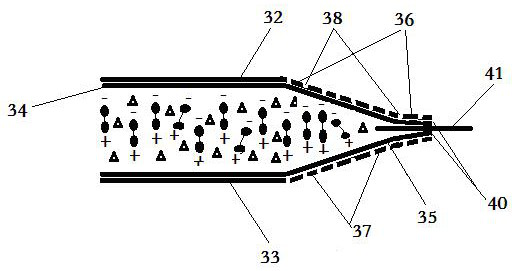

[0044] This embodiment discloses an attached figure 1 The production equipment of the solid-state physical storage battery shown in the figure is composed of a heating furnace 1, a first insulation section 4, a polarization device 2, a second insulation section 5, a cooling forming device 3 and a negative pressure device 6 connected in series, The electrolyte membrane that comes out of the negative pressure device 6 is applied to the making of the forming battery 7 after processing. Because the finally formed electrolyte membrane is a thin film, the outlet of the heating furnace 1 involved in the production equipment, the first insulating section 4, the polarization device 2, the second insulating section 5 and the main body of the cooling forming device 3 are all designed to have A transitional flat channel structure with a certain width.

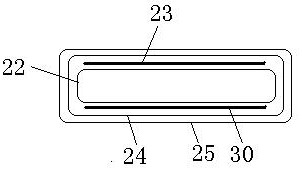

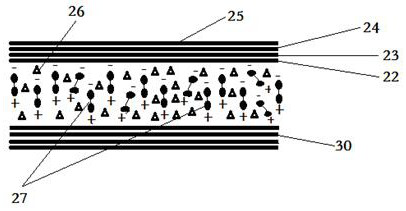

[0045] For the structure of the electrolyte heating furnace in the production equipment, please refer to the attached figure 2 As show...

Embodiment 2

[0053] This embodiment discloses a preparation process of a solid-state physical storage battery based on Embodiment 1. The process is as follows: the electrolyte raw material 8 is placed in the heating furnace 1, the furnace body 10 is heated by the heating material 18, and the heat is transferred into the heating furnace 1 In the body, the electrolyte raw material 8 in the heating furnace 1 is started to be heated, and the stirrer 13 is also continuously stirring the electrolyte raw material 8, the purpose is to make the electrolyte raw material 8 be heated more evenly, and as the temperature of the electrolyte raw material 8 continues to rise, it is composed of powder particles The state gradually melts into a liquid state, and the temperature signal is transmitted to the temperature controller 14 through the temperature sensor 15 in the heating furnace 1 body. After reaching a predetermined temperature, the temperature controller 14 cuts off the power supply and stops heatin...

Embodiment 3

[0055]This embodiment provides a shaped battery structure, the shaped battery structure is made by processing the polar electrolyte film 41 obtained through the preparation process of Example 2, and the shaped battery structure includes a thin film electrolyte 46, polar electrolyte film 41 Electrolyte film negative terminal 47, polar electrolyte film positive terminal 48, battery positive terminal 49, battery positive terminal dielectric 50, battery negative terminal 51, battery negative terminal dielectric 52, battery positive lead 53, battery negative lead 54, A storage battery made of thin film electrolyte 46 . The solid-state physical battery involved in the present invention is different from the existing storage battery structure in that the middle layer of the thinned electrolyte 46 does not contain an electrolyte diaphragm in the middle.

[0056] The storage battery formed by processing the above-mentioned polarized solid electrolyte film has no electrolyte diaphragm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com