High-water-resistance polyester polyol and preparation method thereof

A polyester polyol and water resistance technology, applied in the field of polymers, can solve the problems of poor water resistance and decreased physical properties of materials, and achieve the effects of reducing polarity, reducing ester density and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

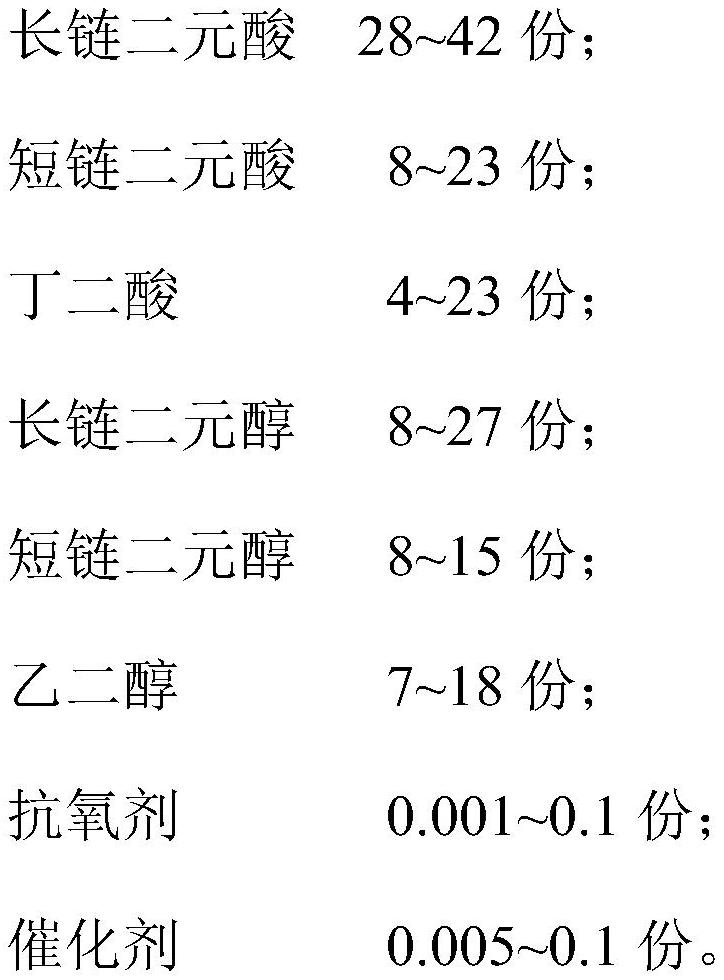

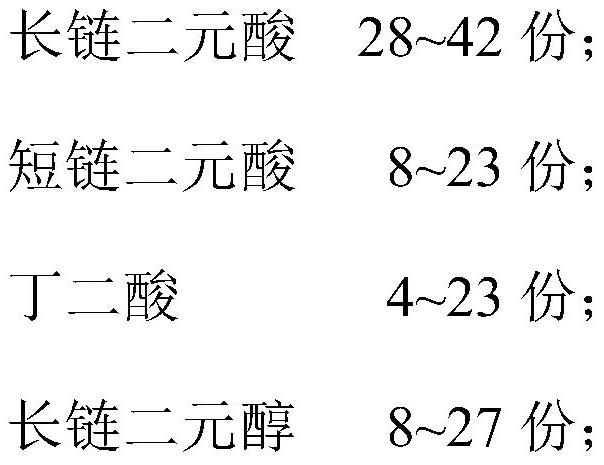

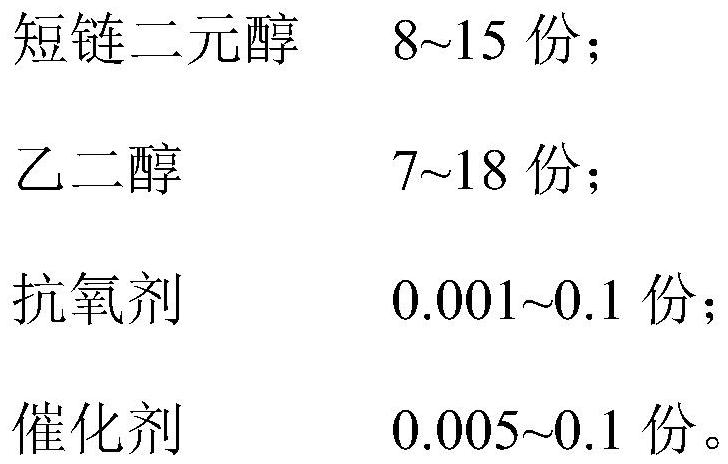

[0028] A kind of polyester polyol is provided in the present embodiment, and the preparation raw material of described polyester polyol comprises following component according to parts by weight:

[0029] Succinic acid: 22.5 parts;

[0030] Adipic acid: 15 parts;

[0031] Dimer acid; 7.5 parts;

[0032] Dodecanedioic acid: 30 parts;

[0033] Ethylene glycol: 7.5 parts;

[0034] 1,2-propanediol: 2.5 parts;

[0035] 1,8-octanediol: 6.25 parts;

[0036] 1,12-Dodecanediol: 8.75 parts;

[0037] Antioxidant 1098: 0.1 part;

[0038] Tetra-n-butyl titanate: 0.05 part.

[0039] The preparation method comprises the following steps:

[0040] (1) Under nitrogen protection, adipic acid, dimer acid, dodecanedibasic acid, 1,2-propanediol, 1,8-octanediol, 1,12-dodecanediol, antioxidant Add agent 1098 into a 2000mL four-necked reaction flask, stir evenly, and then raise the temperature at a constant rate of 15-20°C / h under the protection of nitrogen to 130-150°C, and carry out the est...

Embodiment 2

[0043] A kind of polyester polyol is provided in the present embodiment, and the preparation raw material of described polyester polyol comprises following component according to parts by weight:

[0044] Succinic acid: 15 parts;

[0045] Adipic acid: 22.5 parts;

[0046] Dimer acid; 7.5 parts;

[0047] Dodecanedioic acid: 30 parts;

[0048] Ethylene glycol: 7.5 parts;

[0049] 1,2-propanediol: 2.5 parts;

[0050] 1,8-octanediol: 6.25 parts;

[0051] 1,12-Dodecanediol: 8.75 parts;

[0052] Antioxidant 1098: 0.1 part;

[0053] Tetra-tert-butyl titanate: 0.05 parts.

[0054] The preparation method comprises the following steps:

[0055] (1) Under nitrogen protection, adipic acid, dimer acid, dodecanedibasic acid, 1,2-propanediol, 1,8-octanediol, 1,12-dodecanediol, antioxidant Add agent 1098 into a 2000mL four-necked reaction flask, stir evenly, and then raise the temperature at a constant rate of 15-20°C / h under the protection of nitrogen to 130-150°C, and carry out the...

Embodiment 3

[0058] A kind of polyester polyol is provided in the present embodiment, and the preparation raw material of described polyester polyol comprises following component according to parts by weight:

[0059] Succinic acid: 12 parts;

[0060] Adipic acid: 12 parts;

[0061] Dodecanedioic acid: 36 parts;

[0062] Ethylene glycol: 12 parts;

[0063] 1,2-propanediol: 4 parts;

[0064] 1,8-octanediol: 6 parts;

[0065] 1,12-Dodecanediol: 18 parts;

[0066] Antioxidant 1098: 0.1 part;

[0067] Tetra-n-butyl titanate: 0.05 part.

[0068] The preparation method comprises the following steps:

[0069] (1) Under nitrogen protection, add adipic acid, dodecanedibasic acid, 1,2-propanediol, 1,8-octanediol, 1,12-dodecanediol, and antioxidant 1098 into 2000mL In a four-necked reaction flask, stir evenly, then raise the temperature at a constant rate of 15-20°C / h under the protection of nitrogen, and raise the temperature to 130-150°C, and carry out the esterification and dehydration rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com