Preparation method for mixed wax for printing oil

A printing ink and wax mixing technology, which is applied in inks, applications, household appliances, etc., can solve problems such as uneven mixing, complex components, and poor compatibility of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing printing ink mixed wax, which is realized through the following steps:

[0026] Step 1. Preparation of water phase

[0027] In parts by weight, add 1000 parts of water and 0.5 part of polyvinyl alcohol into the pressure reactor, and stir evenly.

[0028] Step 2. Preparation of oil phase

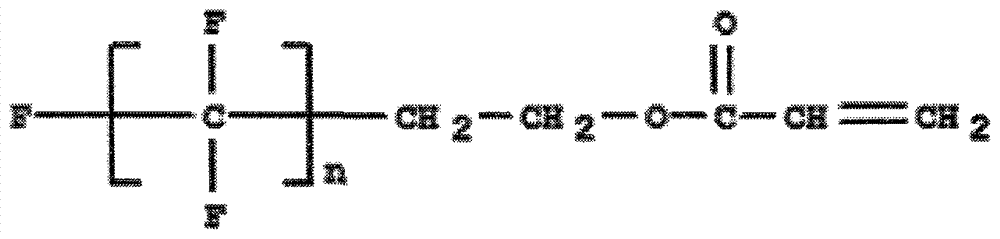

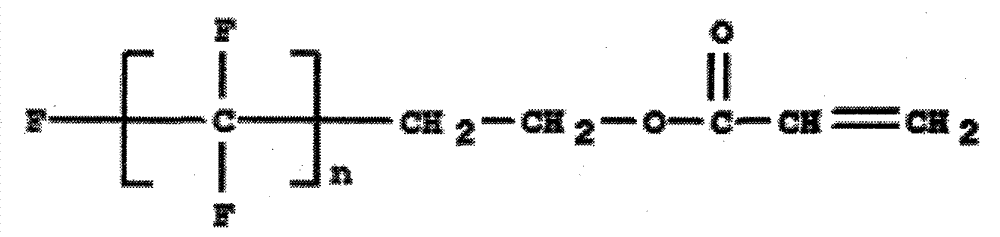

[0029] In parts by weight, mix 100 parts of PE wax and 4 parts of perfluoroalkyl ethyl acrylate monomer, add 0.2 parts of peroxide initiator, and stir evenly.

[0030] Step 3. Suspension Polymerization

[0031] Add the oil phase solution prepared in the beaker in step 2 to the pressure reactor equipped with the prepared water phase in step 1, stir slowly and then quickly, then react at 50°C for 10 hours, discharge the material after the reaction, and wash with water Microspheres until the water is clear to obtain the product.

[0032] Step 4. Blending and crushing

[0033] Mix 94 parts of polyethylene wax powders grafted on the surface...

Embodiment 2

[0035] Mix 85 parts of polyethylene wax powders grafted on the surface obtained in step 3 with 15 parts of PTFE powders, grind and crush them by weight in a fluidized bed jet mill to obtain this product. The number is SX-2.

Embodiment 3

[0037] Mix 98 parts of the surface-grafted polyethylene wax powder obtained in Step 3 with 2 parts of PTFE powder, grind and crush the weight in a fluidized bed jet mill to obtain this product. The number is SX-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com