Method for manufacturing a zinc electrode by wet process

A zinc electrode and manufacturing method technology, applied in the field of electrochemical cells, can solve the problems of complex electrode manufacturing method, inability to effectively limit the formation of dendrites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

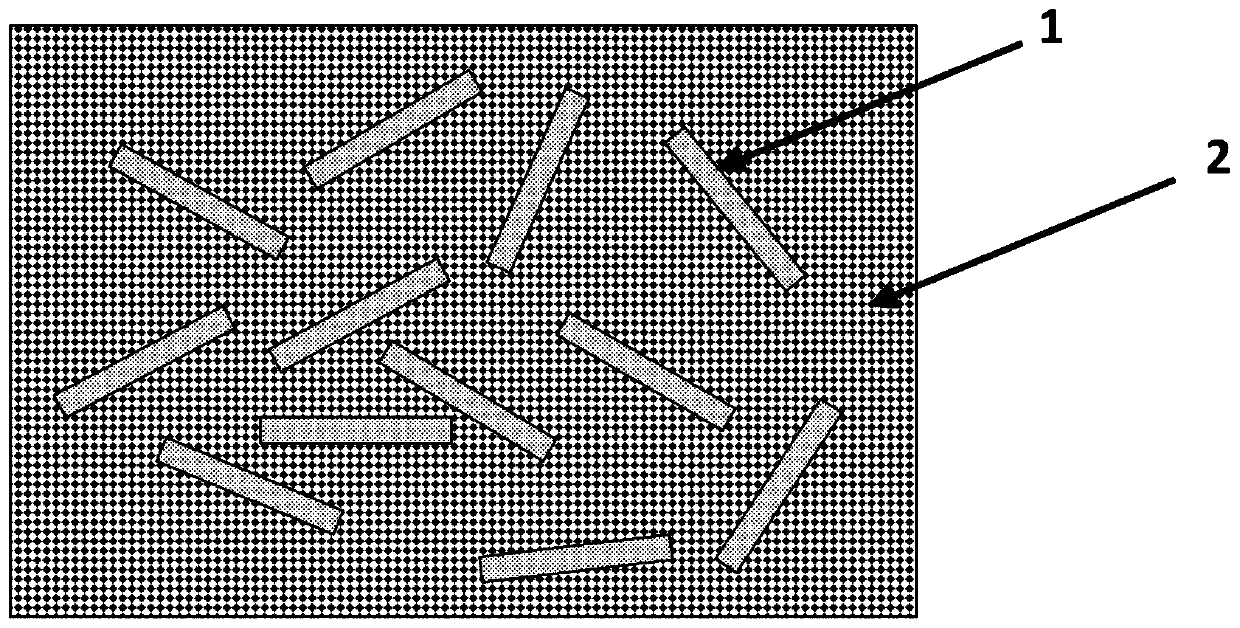

Image

Examples

Embodiment Construction

[0119] Zinc electrodes were prepared by the method according to the invention.

[0120] In the case of this example, the reagent amounts shown in Table 1 were used.

[0121] [Table 1]

[0122] Reagent quantity ZnO 150g Ca(OH) 2

30g Deionized water 30mL PTFE 20mL ethanol 30mL

[0123] Zinc oxide powder (Merck Emsure) was mechanically mixed with calcium hydroxide (Merck) in a mixer at 23°C for 5 minutes. While keeping the mixer running, add deionized water to the mixture at a constant rate over about 30 seconds while providing good mixture homogeneity. Adding water will form calcium zincate crystals.

[0124] The mixture was kept under stirring for 3 minutes. Then, a 60% strength aqueous suspension of PTFE (Aldrich) was added within 1 minute.

[0125] The mixture was kept stirring again for 5 minutes, during which time calcium zincate crystals continued to form and grow.

[0126] The maturation reaction was interrupted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com