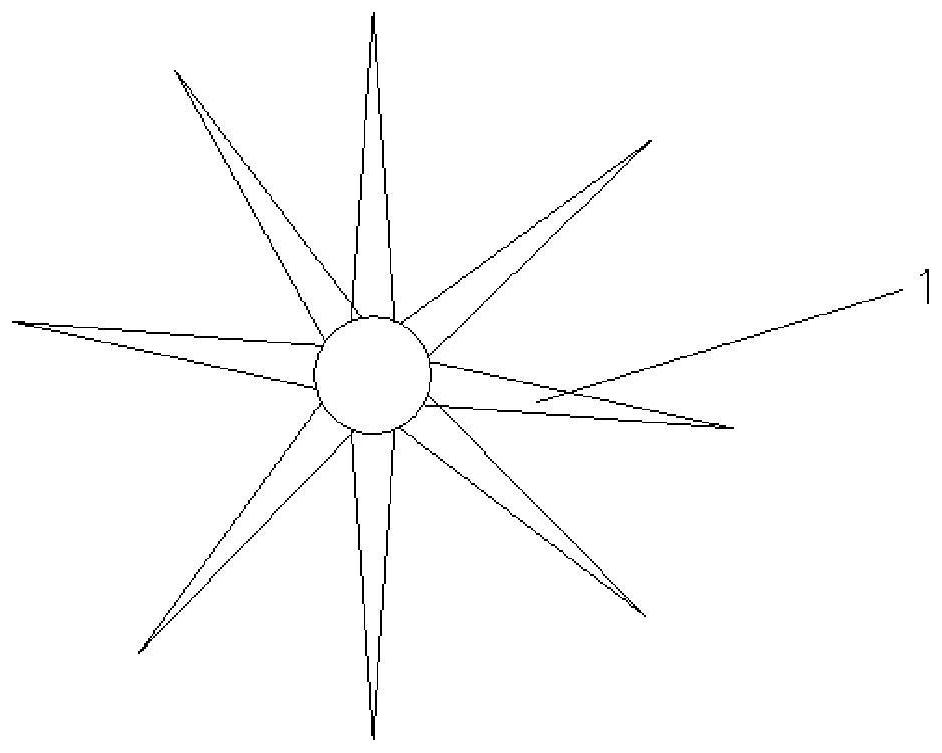

Radial calcium carbonate biological filler, preparation method and application thereof in sewage treatment

A biological filler and sewage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of easy deposition of suspended fillers, reduction of effective biomass, and reduction of mass transfer efficiency, etc. problems, achieve good mud-water separation effect, reduce sludge yield and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Application of radial calcium carbonate biofiller in A2O wastewater treatment process. The sewage treatment capacity of the experimental A2O sewage treatment device is 5 tons / day. The sewage is synthetic wastewater, with a COD of 400mg / L, ammonia nitrogen of 40mg / L, total phosphorus of 3mg / L, and a water temperature of 20°C. The A2O sewage treatment plant has been in operation for three months before and after the addition of radial calcium carbonate biological filler, and the dosage of radial calcium carbonate biological filler is 100mg / L (calculated based on the effective volume of the biochemical pool). Before adding the radial calcium carbonate biological filler, the MLSS is 3000mg / L, the SVI is 120ml / g, the COD removal rate is 90%, the total nitrogen removal rate is 65%, and the total phosphorus removal rate is 87%. After adding radial calcium carbonate biological filler, the sludge SVI dropped to 110ml / g, and the total nitrogen removal rate increased to 67%. The ...

Embodiment 2

[0022] Application of radial calcium carbonate biofiller in A2O wastewater treatment process. The sewage treatment capacity of the experimental A2O sewage treatment device is 5 tons / day. The sewage is synthetic wastewater, with a COD of 400mg / L, ammonia nitrogen of 40mg / L, total phosphorus of 3mg / L, and a water temperature of 20°C. The A2O sewage treatment plant has been in operation for three months before and after adding radial calcium carbonate biological filler, and the dosage of radial calcium carbonate biological filler is 500mg / L (calculated based on the effective volume of the biochemical pool). Before adding the radial calcium carbonate biological filler, the MLSS is 3000mg / L, the SVI is 120ml / g, the COD removal rate is 90%, the total nitrogen removal rate is 65%, and the total phosphorus removal rate is 87%. After adding the radial calcium carbonate biological filler, the sludge SVI decreased to 90ml / g, the removal rate of total nitrogen increased to 69%, and the re...

Embodiment 3

[0024] Application of radial calcium carbonate biofiller in A2O wastewater treatment process. The sewage treatment capacity of the experimental A2O sewage treatment device is 5 tons / day. The sewage is synthetic wastewater, with a COD of 400mg / L, ammonia nitrogen of 40mg / L, total phosphorus of 3mg / L, and a water temperature of 20°C. The A2O sewage treatment plant has been in operation for three months before and after adding radial calcium carbonate biological filler, and the dosage of radial calcium carbonate biological filler is 1000mg / L (calculated based on the effective volume of the biochemical pool). Before adding the radial calcium carbonate biological filler, the MLSS is 3000mg / L, the SVI is 120ml / g, the COD removal rate is 90%, the total nitrogen removal rate is 65%, and the total phosphorus removal rate is 87%. After adding radial calcium carbonate biological filler, the sludge SVI decreased to 75ml / g, the removal rate of total nitrogen increased to 67%, and the remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com