A method of sequestering carbon dioxide

A carbon dioxide and sodium carbonate technology, applied in chemical instruments and methods, organic chemistry, carbonate preparations, etc., can solve the problems of inconspicuous carbon dioxide, loss of adsorbent, and high energy consumption of adsorbent regeneration, to avoid energy consumption and cost-effective. High, avoid energy loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

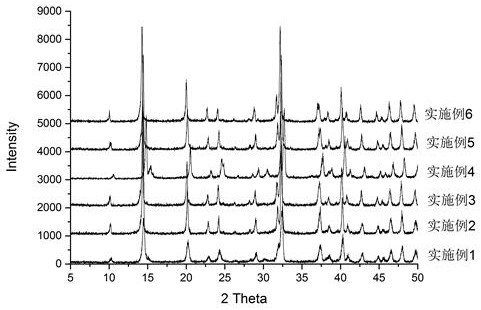

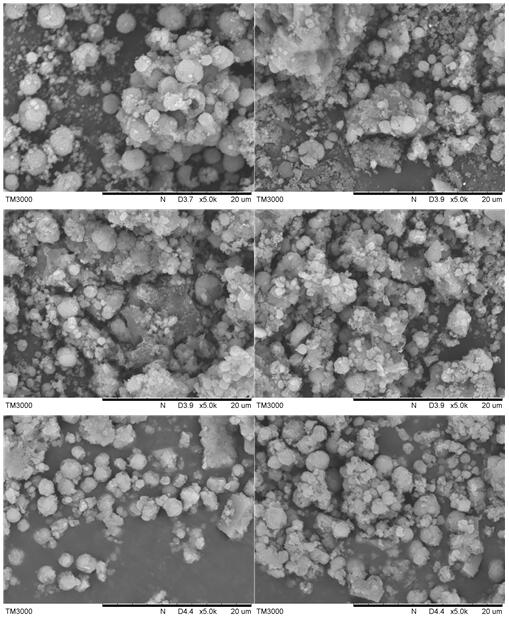

Image

Examples

Embodiment Construction

[0046]The cleaned power plant exhaust gas passes into a reaction bed with sodium sodium carbonate, and sodium bicarbonate is formed at 40 ° C;

[0047]Add the amount of water in sodium hydrogencarbonate, 5% PD / C (the load amount of Pd on C is 10%), stirring, giving hydrogen, the hydrogen pressure in the reactor is maintained at 1 atmospheric pressure, to be solved The solid disappeared pH keeps constant constant constant, and the solution is evaporated, centrifuged and dried to obtain sodium formate solids;

[0048]The resulting formate solid was reacted at 350 ° C for 35 min, i.e. sodium sodium sodium formate was completed.

[0049]The resulting oxalate is used in different laundry powder formulations, the laundry powder preparation process is as follows:

[0050]In accordance with Table 1 components and content, raw materials are performed. (1) Add deionized water to 50-60 ° C, heating to 50-60 ° C, start stirring; (2) to add anionic surfactant, buffer, sodium carbonate, sodium silicate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com