Method for producing ots device, and ots device

一种制造方法、设备的技术,应用在半导体/固态器件制造、电气元件、电固体器件等方向,能够解决困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

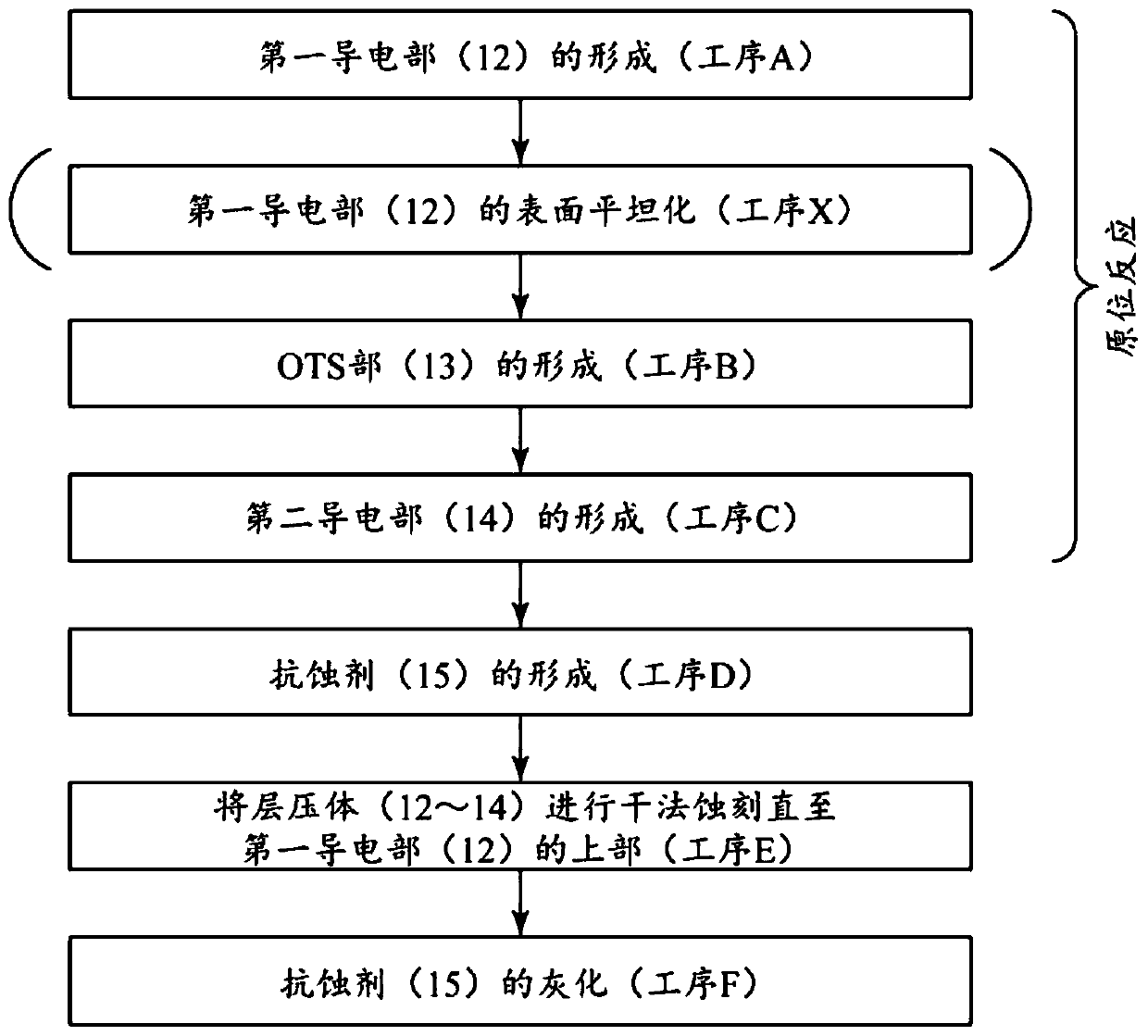

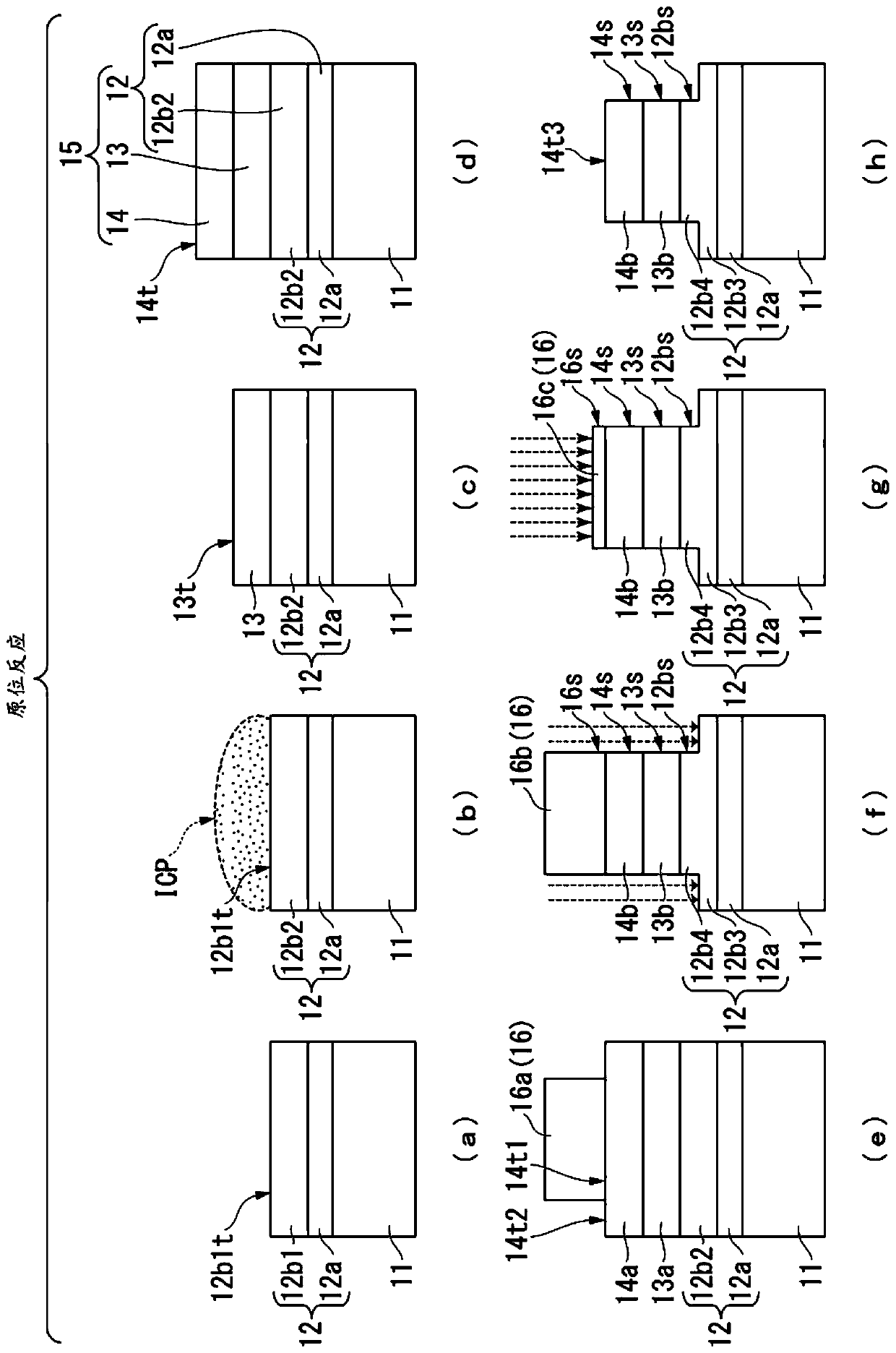

[0086] In Experimental Example 1, a series of processes consisting of the above-mentioned steps A, B, and C were all carried out under a reduced pressure atmosphere (insitu process). In the case of the second conductive portion), in step A, the first conductive portion composed of a lower layer film (Ti film) / an upper layer film (Pt film) is formed on a substrate made of Si by sputtering. Then, the surface profile of the structure formed by the in situ process was evaluated using STM (or AFM).

experiment example 2

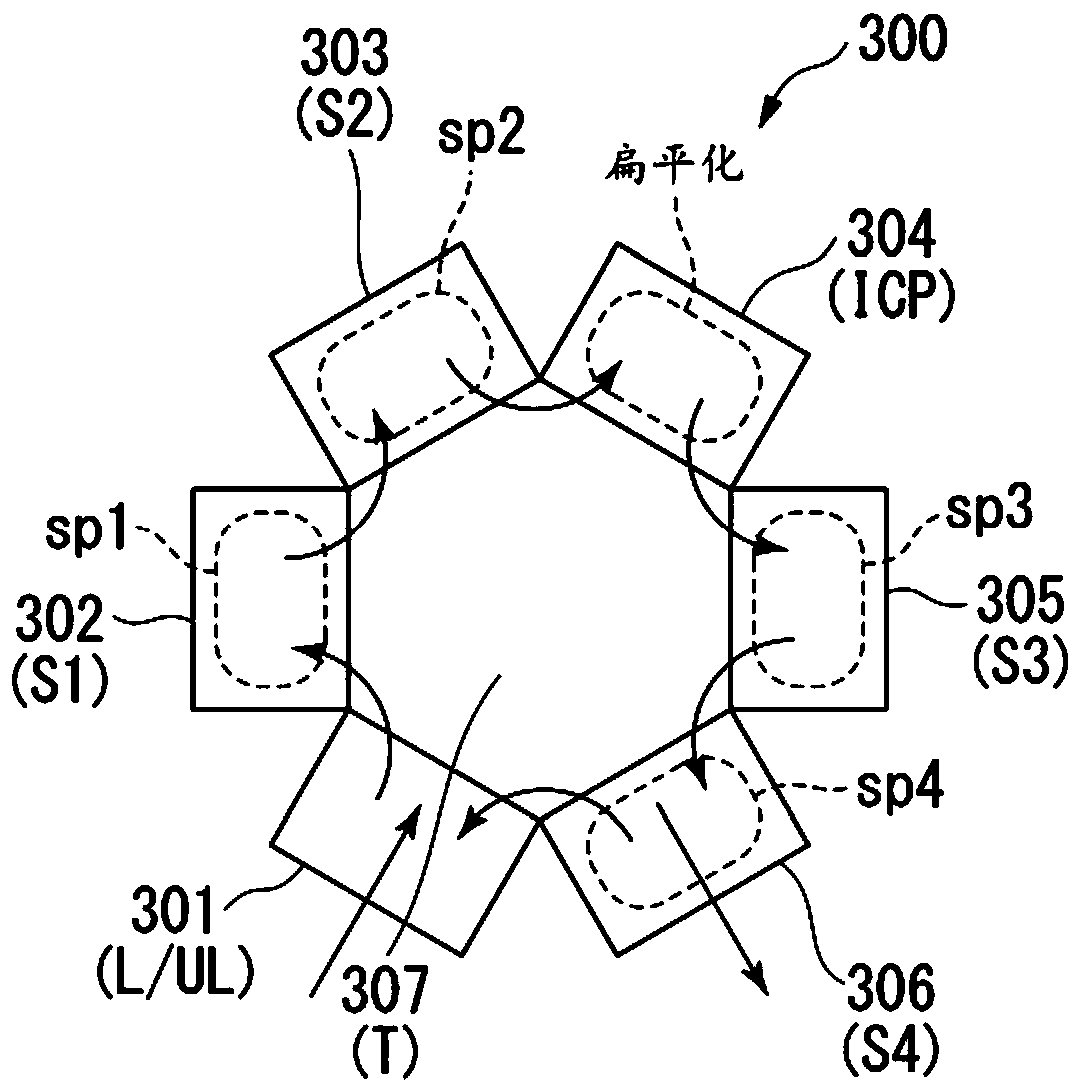

[0088] Experimental Example 2 differs from Experimental Example 1 only in that the ICP process (process X) is performed on the surface of the first conductive part in the insitu process after the first conductive part is produced by the sputtering method in step A and before step B is performed. . Other aspects are the same as Experimental Example 1.

experiment example 3

[0090] Experimental Example 3 differs from Experimental Example 1 only in that the first conductive portion is exposed to the air before Step B is performed after the first conductive portion is formed by the sputtering method in Step A. Other aspects are the same as Experimental Example 1.

[0091] Table 1 is a list including common film formation conditions of Experimental Examples 1 to 3. Except for the TiN film, only Ar gas was used as the process gas. When it is TiN film, use Ar and N 2 formed gas mixture. Only the Ti film was formed at room temperature. All other films were formed at 150°C.

[0092] In addition, Table 1 also shows film formation conditions of a Mo film that can be used instead of TiN constituting the second conductive portion.

[0093] In Table 1, the working pressure represents the pressure at the time of film formation, the power represents the power applied to the target, the Ar gas flow rate represents the flow rate of Ar gas introduced into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com