A kind of sulfonated polyarylether sulfone nanofiltration membrane and preparation method thereof

A sulfonated polyaryl ether sulfone, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, to achieve the effect of simple preparation method, excellent water flux and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

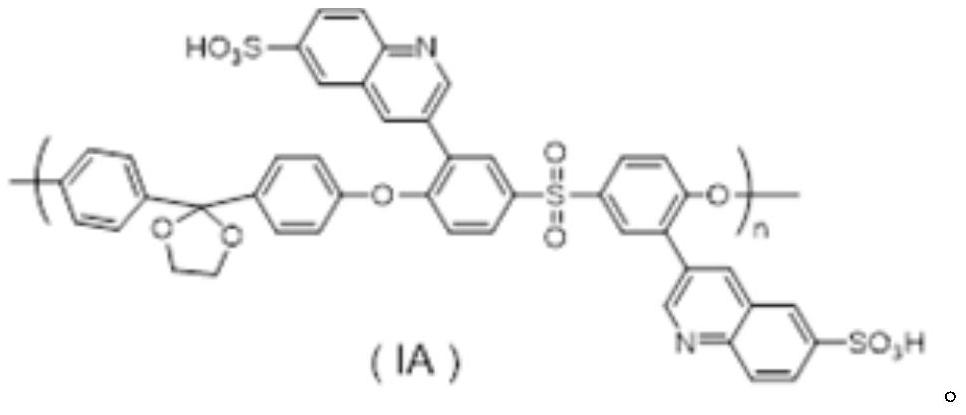

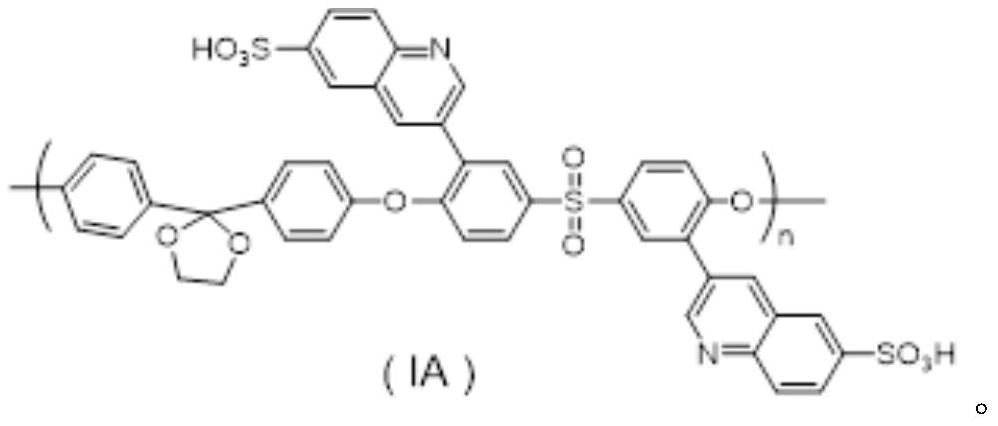

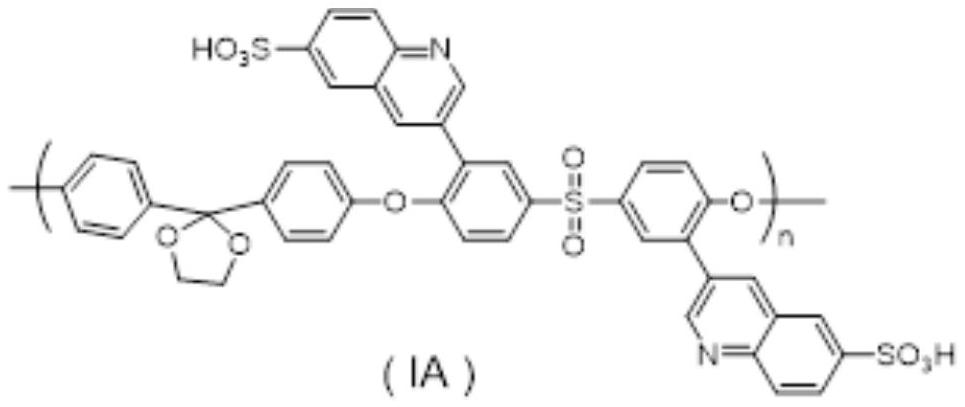

[0038] Embodiment 1: Synthesis of sulfonated polyarylethersulfone (IA)

[0039]

[0040] Step 1: Synthesis of 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))biquinoline (I-c)

[0041]

[0042] Dissolve 4,4'-sulfonylbis(2-bromo-1-fluorobenzene) (8.24g, 20mmol) in 100mL tetrahydrofuran, add 0.2g tetrakis(triphenylphosphine)palladium, add quinoline-3-boronic acid (7.26g, 42mmol), heated to reflux for 12 hours under nitrogen protection. After the reaction, cool to room temperature, add 100mL of water, continue to stir for 1 hour, and filter to obtain the crude product of 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))biquinoline. Recrystallized from toluene, the final product 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))diquinoline crude product was 8.63g, and the yield was 85%.

[0043] MS m / z: 509.2[M+H]+

[0044] Step 2: Synthesis of polyarylethersulfone (I-e)

[0045]

[0046] Add 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))biquinoline (5.08g, 10mmol), 4,4'-(1,3-dioxo Pentacycl...

Embodiment 2

[0050] Example 2: Preparation of sulfonated polyarylethersulfone nanofiltration membrane 1

[0051] Add sulfonated polyarylethersulfone (IA) (3g) into N-methylpyrrolidone (7g), heat to 60°C under stirring condition, sulfonated polyarylethersulfone (IA) is completely dissolved, continue stirring for 12 hours to obtain a uniform casting solution, and then stand at 60°C for 12 hours to defoam. Pour the defoamed casting solution onto a clean glass plate, and scrape it with a spatula to form a uniform nascent film of 100 μm. After the nascent film was volatilized for 60 seconds, it was removed from the glass plate and slowly placed in 40°C deionized water to solidify into a film. The above membrane was washed three times with deionized water to obtain a sulfonated polyarylethersulfone nanofiltration membrane 1 .

Embodiment 3

[0052] Example 3: Preparation of sulfonated polyarylethersulfone nanofiltration membrane 2

[0053] Add sulfonated polyarylethersulfone (IA) (2.8g) into N-methylpyrrolidone (7.2g), and heat to 60°C under stirring condition, the sulfonated polyarylethersulfone (IA) is completely dissolved, continue Stir for 12 hours to obtain a uniform casting solution, and then stand at 60° C. for 12 hours to defoam. Pour the defoamed casting solution onto a clean glass plate, and scrape it with a spatula to form a uniform nascent film of 100 μm. After the nascent film was volatilized for 60 seconds, it was removed from the glass plate and slowly placed in 40°C deionized water to solidify into a film. The above membrane was washed three times with deionized water to obtain the sulfonated polyarylethersulfone nanofiltration membrane 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com