Vertical disc milling cutter device and reverse milling method thereof

A disc milling cutter, vertical technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of abnormal tool wear, abnormal deformation, and high tool return rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

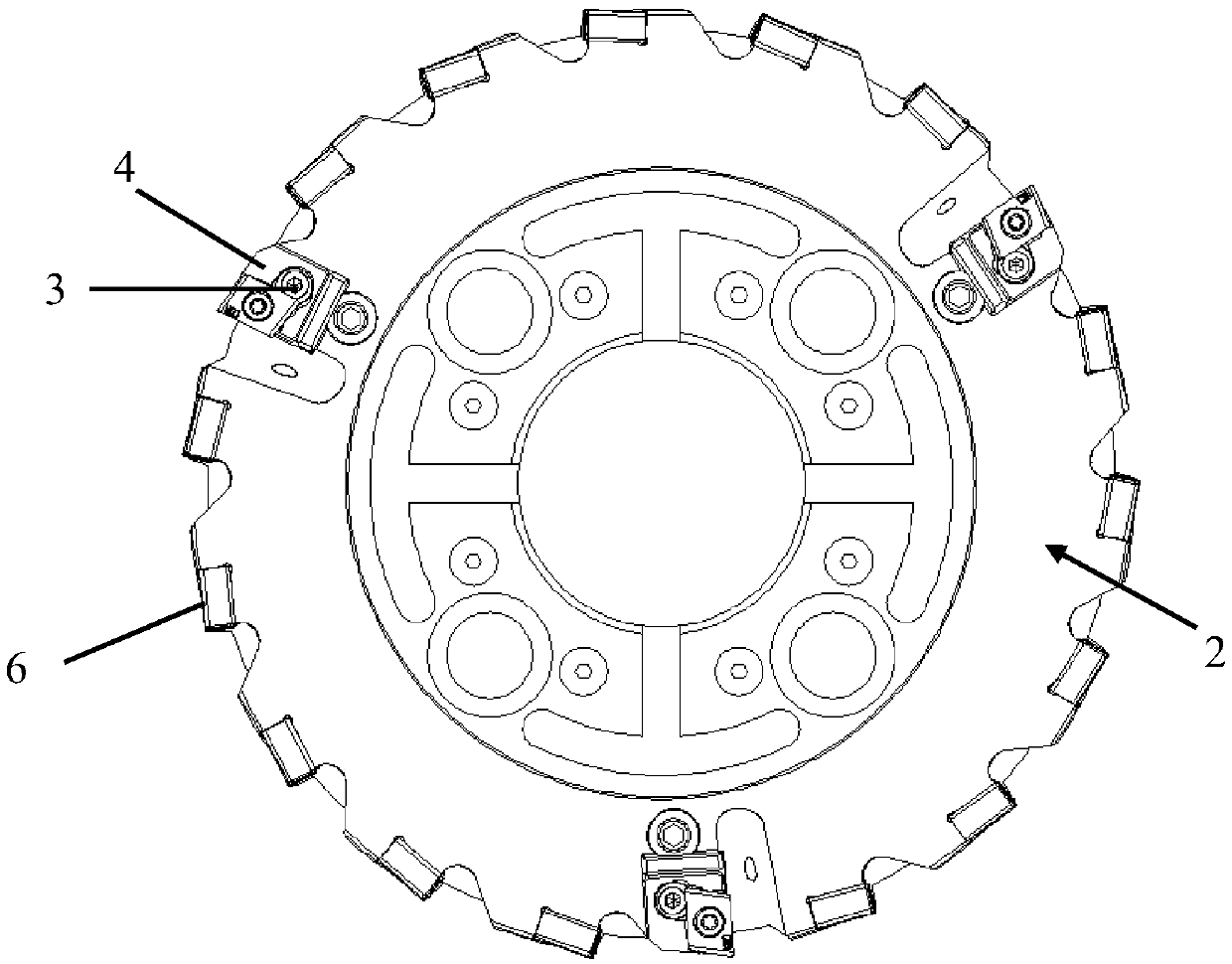

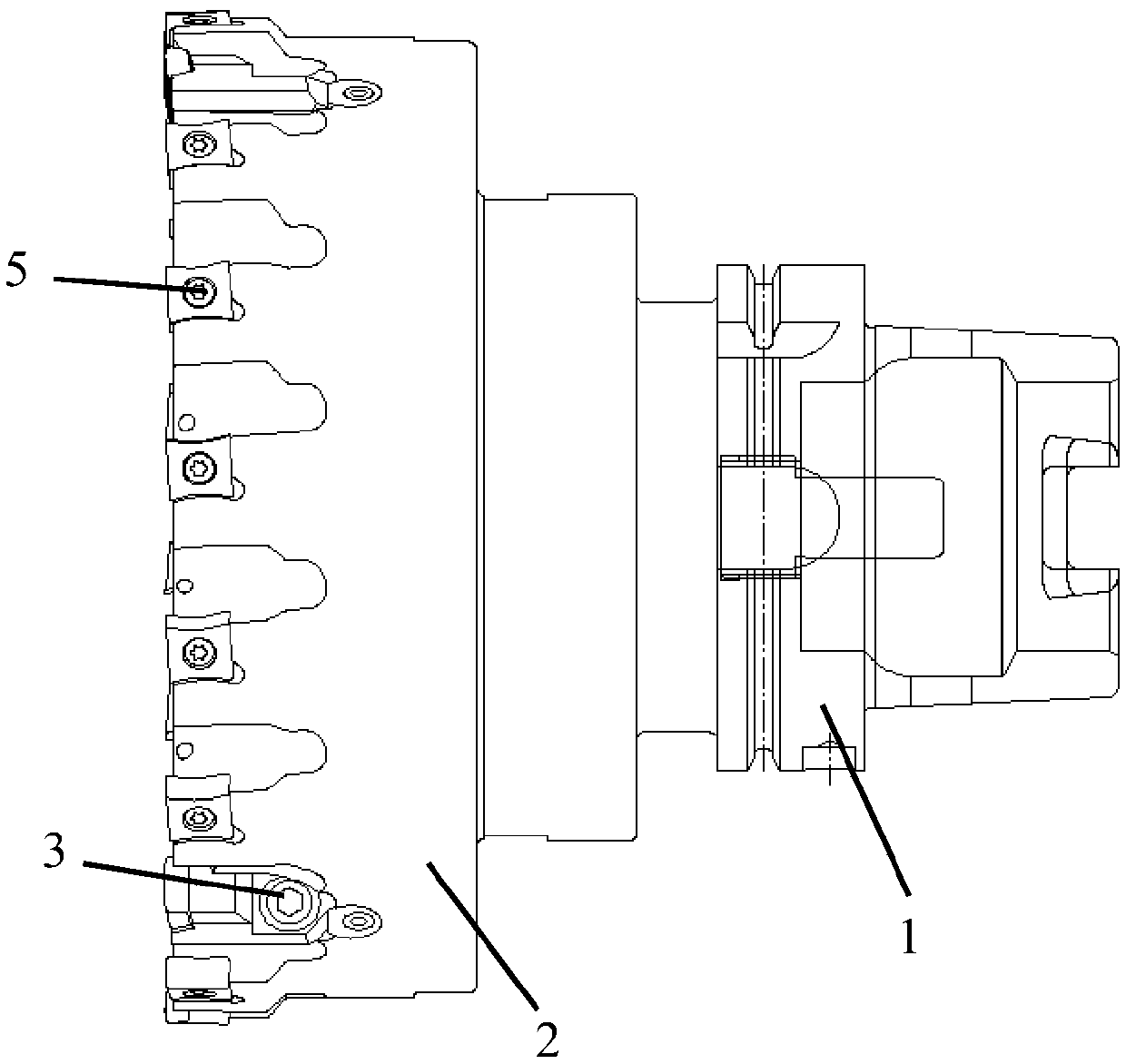

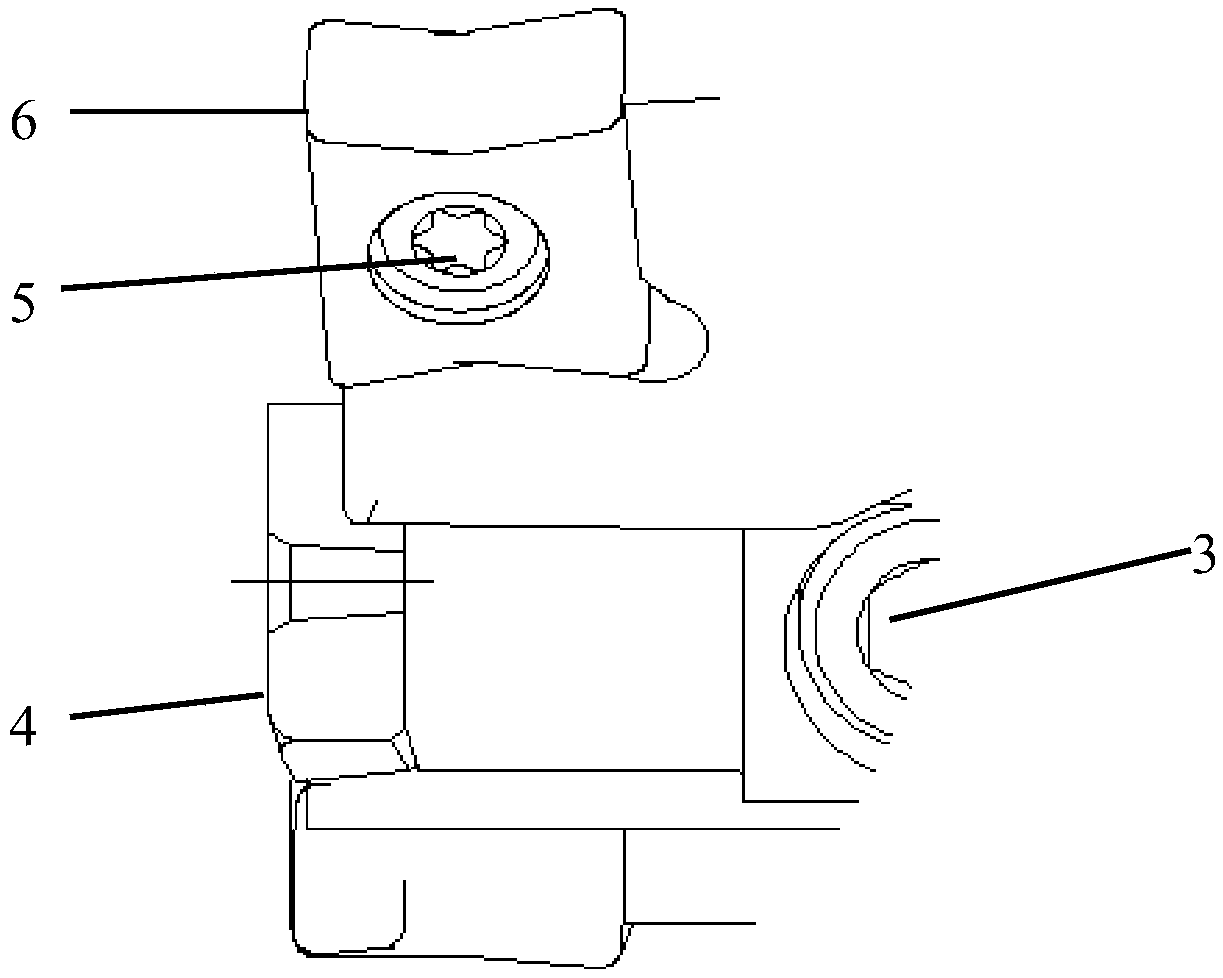

[0023] The following with attached figure 1 and Figure 4 A vertical disk milling cutter device and its reverse milling processing method of the present invention will be further described in detail.

[0024] A kind of vertical disk milling cutter device of the present invention, please refer to Figure 1 to Figure 4 Each accompanying drawing comprises a handle 1 and a cutter head 2, and one end of the cutter head 2 is detachably fixedly connected to one end of the handle 1, and the other end of the cutter head 2 is circumferentially spaced at least There are five blade grooves, at least one blade groove is fixedly connected with a fine blade 4 through an adjusting bolt 3 , and at least four of the blade grooves are fixedly connected with a rough blade 6 through fixing bolts 5 . In this way, one end of the cutter head 2 is connected to one end of the knife handle 1, and the connection between the two can also be released, which is convenient for installation and maintenance....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com