Elevator counterweight guide rail guidance stroke measurement device based on sensor technology

A sensor technology and counterweight guide rail technology, which is applied in the field of elevator counterweight guide rail guidance stroke measurement device based on sensor technology, can solve the problems of large cumulative error, reduced on-site measurement accuracy, and short tape measure, so as to improve measurement accuracy and improve Test the effect of the scientific level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

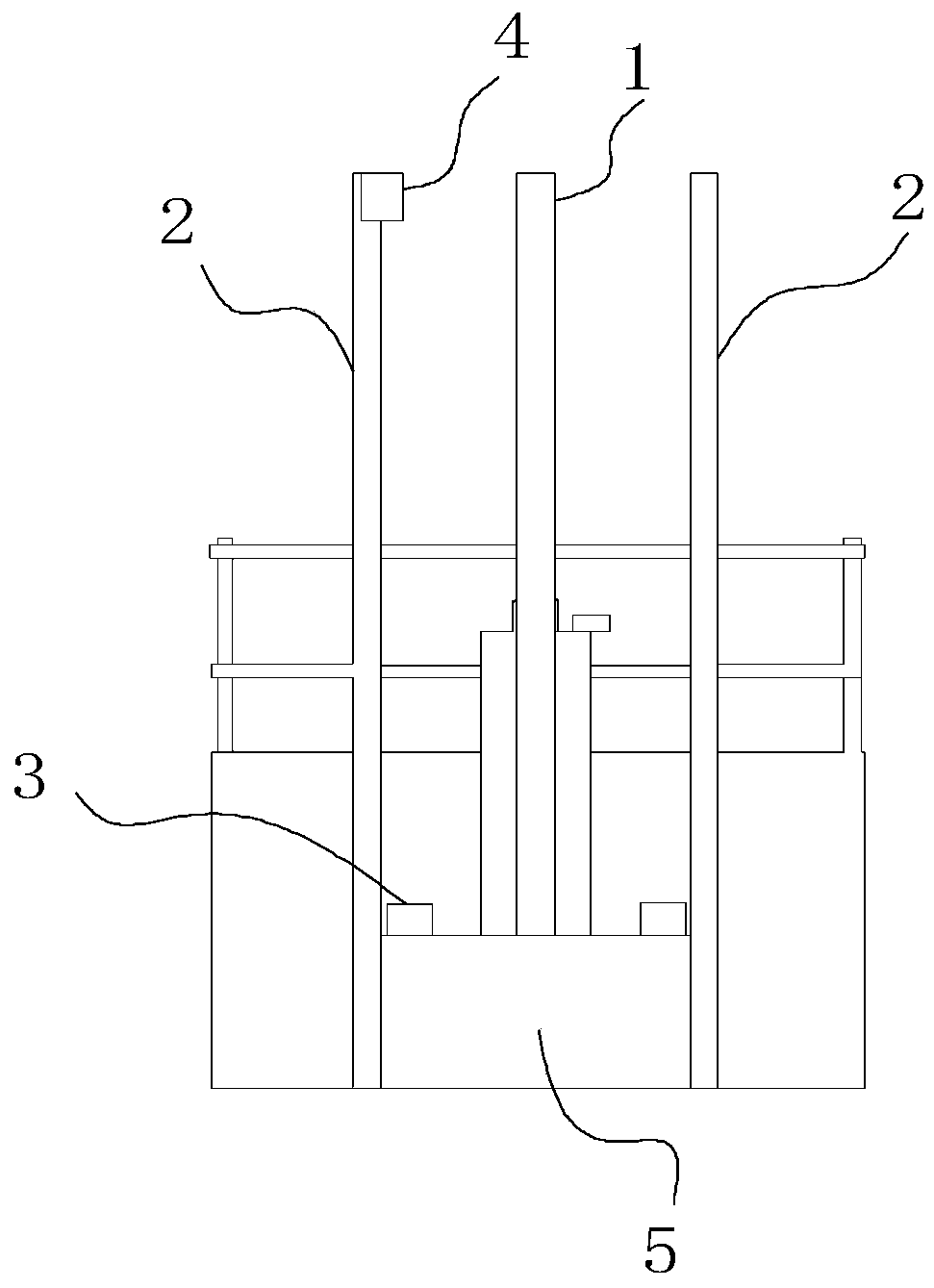

[0047] like Figure 1-7 As shown, an elevator counterweight guide rail guidance stroke measuring device based on sensor technology in this implementation is used to measure the guidance stroke of the elevator counterweight guide rail 2, including a support 6, a walking wheel 7, a positioning component, a measuring robot 4 and a remote Jogbox.

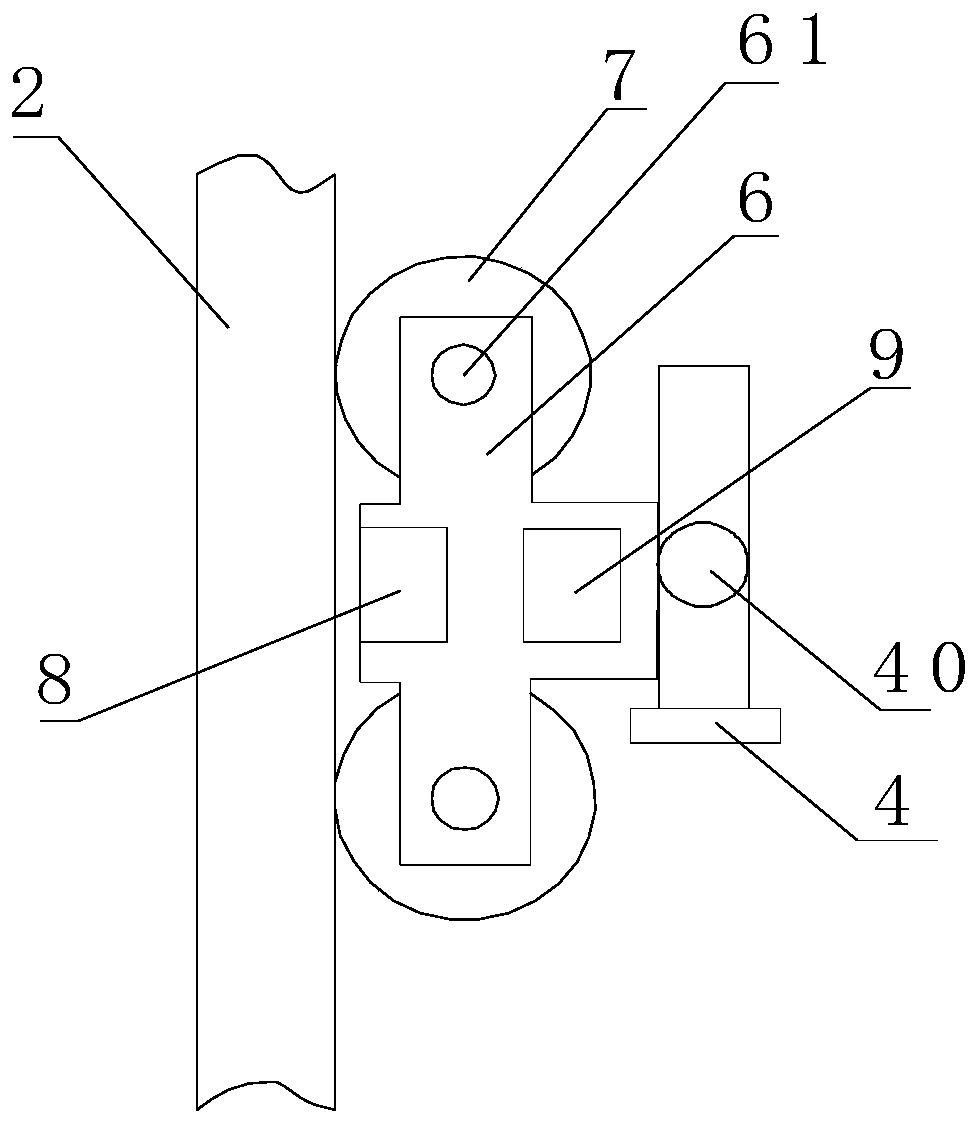

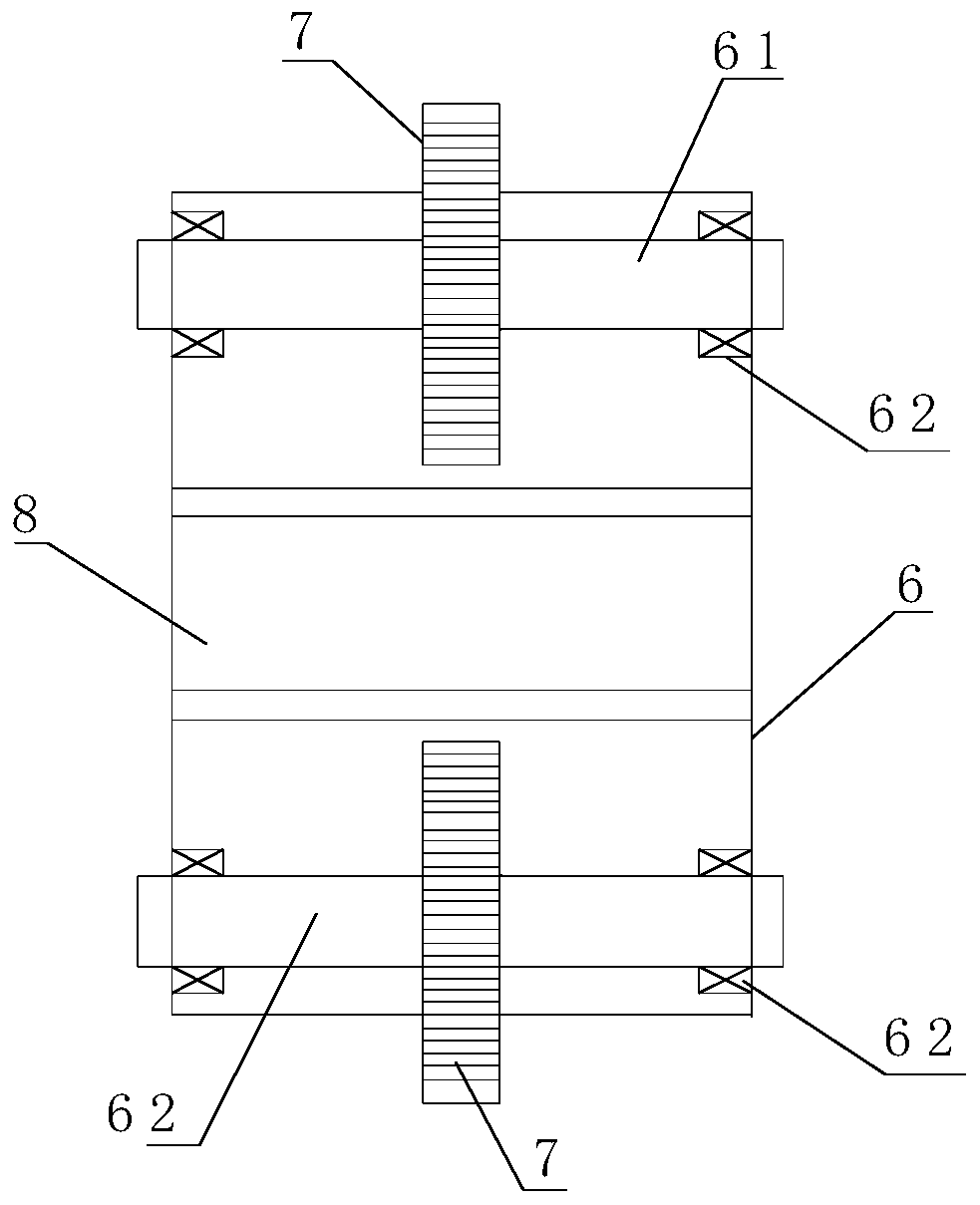

[0048] read on figure 2 , the support 6 is a bearing support, which covers the guide surface of the elevator guide rail. There can be one traveling wheel 7, or a plurality of parallel ones. In this embodiment, the traveling wheels 7 are two arranged up and down, and each traveling wheel 7 is fixed on the support 6 through a mandrel 61 rotation. And the running wheel 7 is arranged on the two sides facing the guide surface on the elevator counterweight guide rail 2 . Driven by the driving device, the driving device is a driving motor 9 in the present embodiment, and the driving motor 9 is connected on the mandrel 61 through the rotati...

Embodiment 2

[0059] The elevator guide rail guiding stroke measuring device provided by this embodiment adds a guide mechanism on the basis of embodiment 1, and the guide mechanism includes a guide rod 30, a guide frame 31, and a support portion 32; On the shell; the guide rod 30 is fixed laterally at one end of the support portion 32, and the other end is connected to the guide frame 31, wherein the guide rod 30 is connected with the body 20 and the support 6 as an integral structure.

[0060] The guide mechanism connects the body 20 of the fixed part and the support 6 as a whole. When the measuring device runs on the guide rail, the guide bar 30 fixes the entire support 6 laterally. When the traveling wheels 7 move, the whole device is more stable. The side of the robot 4 is protected, which is beneficial to prevent the lateral deviation of the measuring robot 4 .

Embodiment 3

[0062] The elevator counterweight guide rail guidance stroke measuring device provided in this embodiment has two displacement sensors 26 and two pressure sensors 25 added on the basis of embodiment 1, and the displacement sensors 26 are correspondingly installed on the body 20, and its signal path Connected to the microprocessor 48 , the pressure sensor 25 is correspondingly located at one end of the elastic member 23 , and its signal is sent to the microprocessor 48 . The distance deviation of the data transmitted by the two displacement sensors 26 shows whether the traveling wheel 7 is walking on the middle straight line of the counterweight guide rail 2, and the pressure signal of the pressure sensor 25 also reflects the force situation of the two positioning plates 21, which can be analyzed according to the values The running state of the walking wheel 7 is convenient for surveyors to observe and correct adjustments.

[0063] As on the basis of the above-mentioned embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com