Shear lifting mechanism type trailer

A mechanism-type, jacking-up mechanism technology, applied in the direction of lifting frames, cranes, lifting devices, etc., can solve the problems of large volume, inconvenient limit fixation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

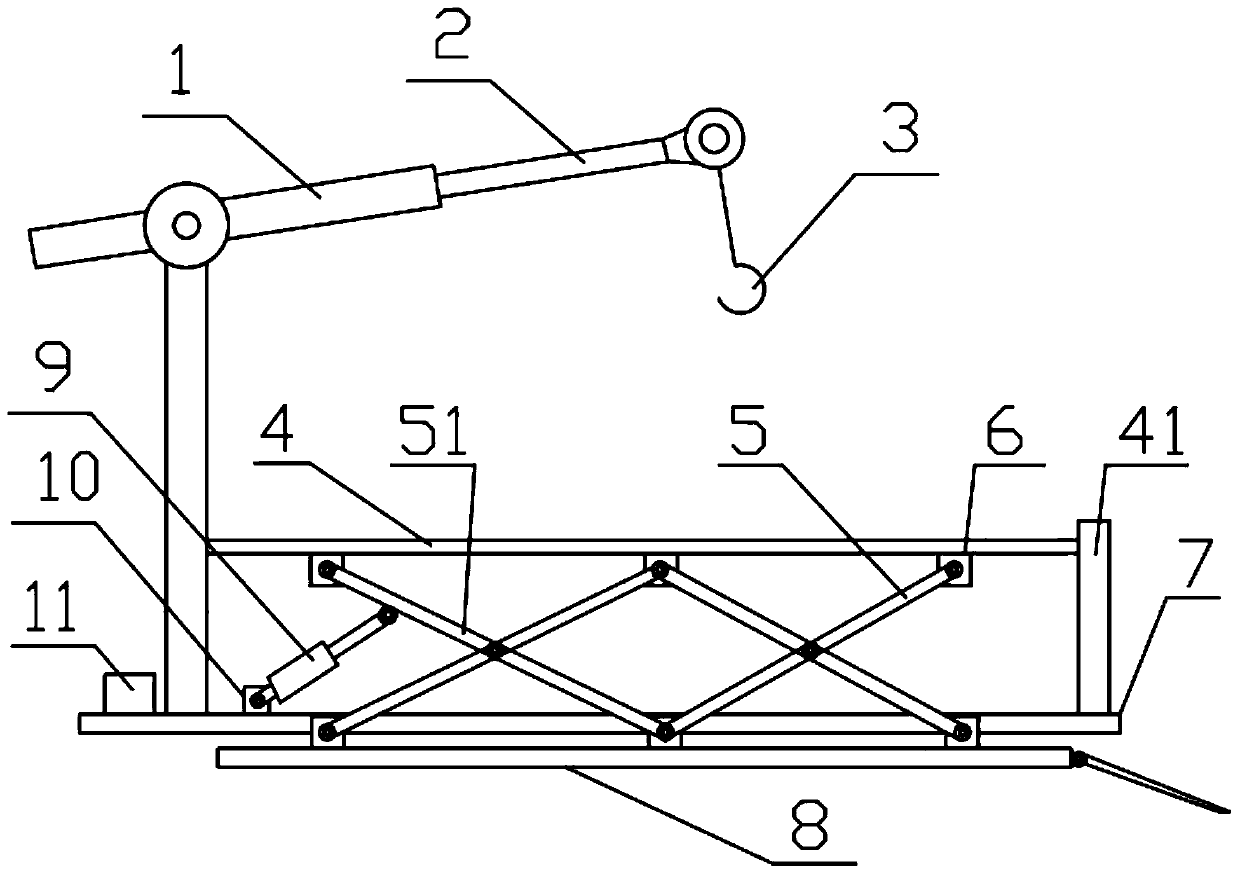

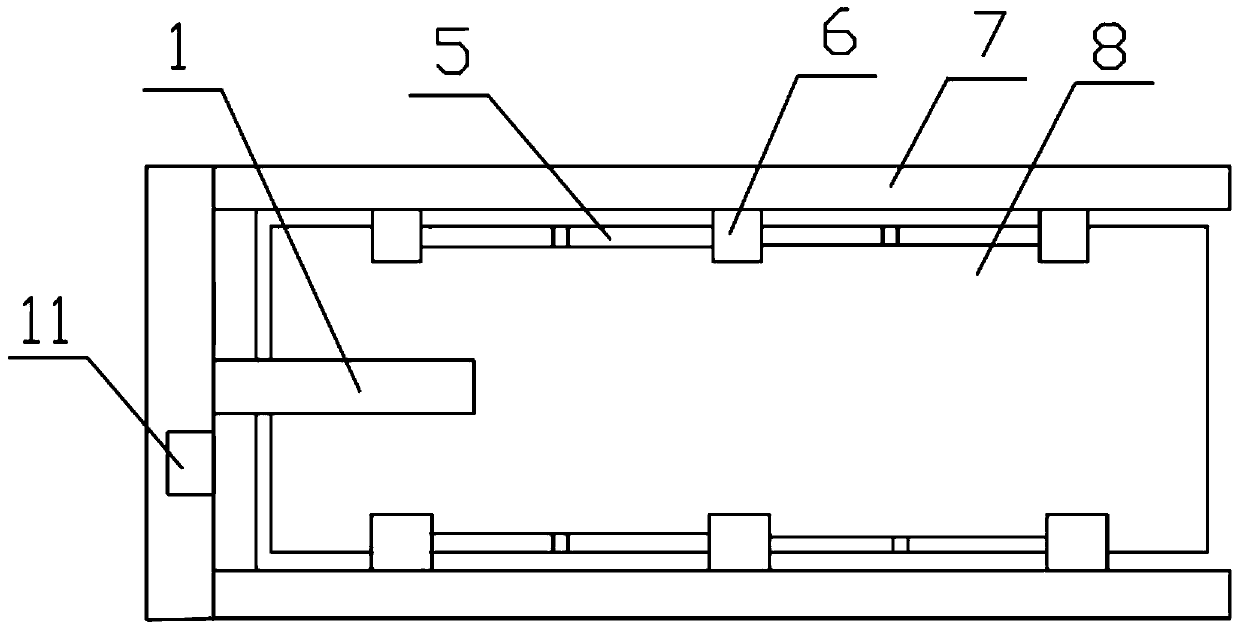

[0030] A special trailer for lifting accident cars with a scissor lift mechanism, including: 1 small crane, 2 small crane telescopic arms, 3 hooks, 4 trailer guardrail, 5 scissor fork type jacking mechanism, 6 mounting base, 7 trailer frame, 8 Trailer floor, 9 hydraulic cylinders, 10 hydraulic cylinder seats, 11 hydraulic control mechanism.

[0031] The small crane 1 is connected with the small crane telescopic arm 2, the hook 3 is connected with the small crane telescopic arm 2 through a wire rope, the small crane 1 is fixed on the trailer frame 7, the hydraulic control mechanism 11 is fixed on the trailer frame 7, and the trailer guardrail 4 It is fixedly connected with the trailer frame 7, the scissor-fork lifting mechanism 5 is fixedly connected with the trailer guardrail 4 through the installation seat 6, the hydraulic cylinder 9 is connected with the scissor-fork lifting mechanism 5, and the hydraulic control mechanism 11 is directly connected with the oil cylinder 9 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com