Automatic control method combining constant water level and constant water quantity of sewage plant

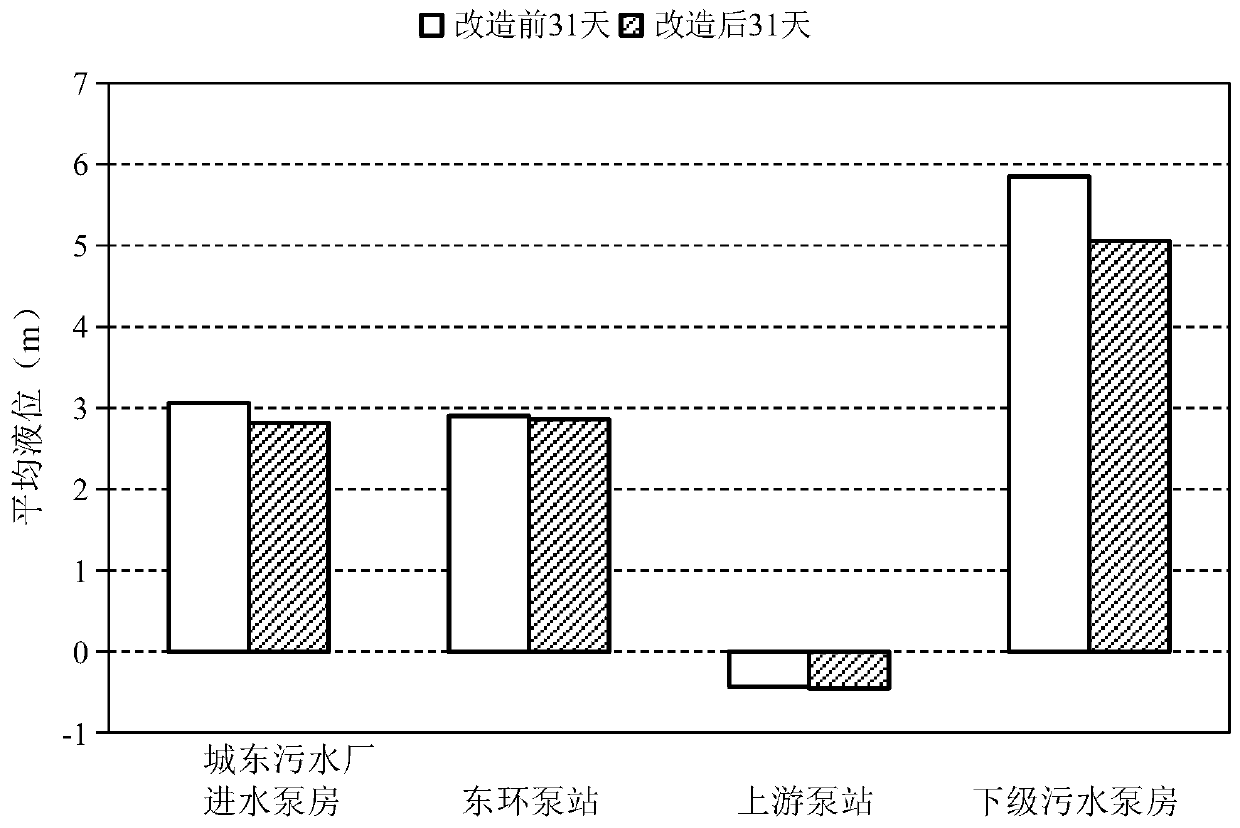

A sewage plant, constant water level technology, applied in chemical instruments and methods, water treatment parameter control, biological water/sewage treatment, etc. Influence and other problems, to achieve the effect of stabilizing production operation and reducing water level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

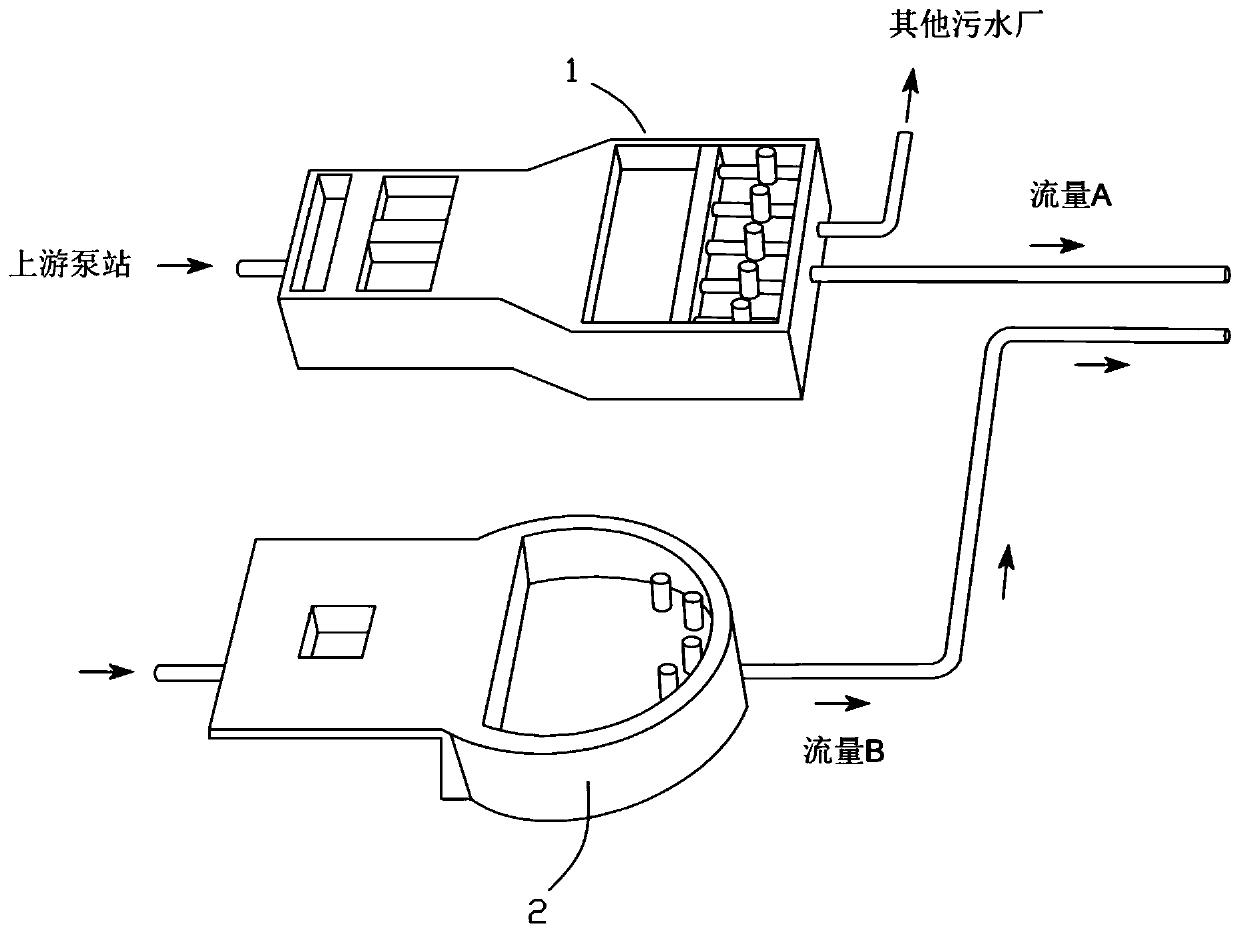

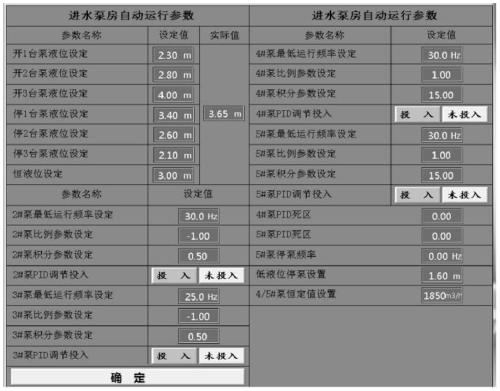

[0016] The invention provides an automatic control method combining constant water level and constant water volume in a sewage plant. The method is suitable for sewage plants with N water inlets and M water transfer channels, wherein N is greater than or equal to 2, and M is greater than or equal to 1. The wastewater treatment plant has an intake pumping station 1 and at least one pumping station 2 . Inlet pump room 1 is equipped with an inlet pump and a transfer pump, wherein the incoming water from inlet pump room 1 is supplied by the upstream pump station, and the inlet pump transports the water to the biological pool in the sewage plant. The flow rate of the inlet pump is A, and the transfer pump will The water is diverted to other sewage plants. The pumping station 2 of the sewage plant alone transports water to the biological pool in the plant, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com