Two-component condensation type silicone adhesive, composition forming same and application thereof

A silicone adhesive, condensation-type technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of fast curing, fast bonding performance, anti-aging performance and lack of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In a preferred embodiment, the preparation method of the hydrate of trialkoxysilane a and dialkoxysilane without amino group comprises: adding trialkoxysilane a and dialkoxysilane according to a predetermined ratio Put it into the reaction vessel, fill it with nitrogen for protection, stir evenly, control the temperature of the mixture at 20-30°C, add tin catalyst, stir rapidly, control the temperature of the system at 20-40°C, add deionized water dropwise within 1-1.5h Into the reaction system, the temperature was raised to reflux, kept for 2 hours, and the co-hydrolyzed product was obtained after cooling down. Preferably, the catalyst is used in an amount of 0.2-0.35%, more preferably 0.23%, 0.25%, and 0.3%, as a percentage of the total weight of trialkoxysilane and amino group-free dialkoxysilane.

[0025] Preferably, the amount of deionized water is 7-8%, more preferably 7.2%, 7.5%, 7.7%, based on the percentage of the total weight of trialkoxysilane and dialkoxysil...

Embodiment 1

[0091] (1) Preparation of the second component

[0092] 100 parts of 1000cp methyl silicone oil, 30 parts of fumed silica treated with hexamethyldisilazane, 20 parts of methyltrimethoxysilane, 25 parts of XL-1, 30 parts of P-1, dilauric acid 0.2 parts of dibutyltin, mixed evenly in a planetary stirring tank.

[0093] (2) Preparation of two-component condensation type silicone adhesive

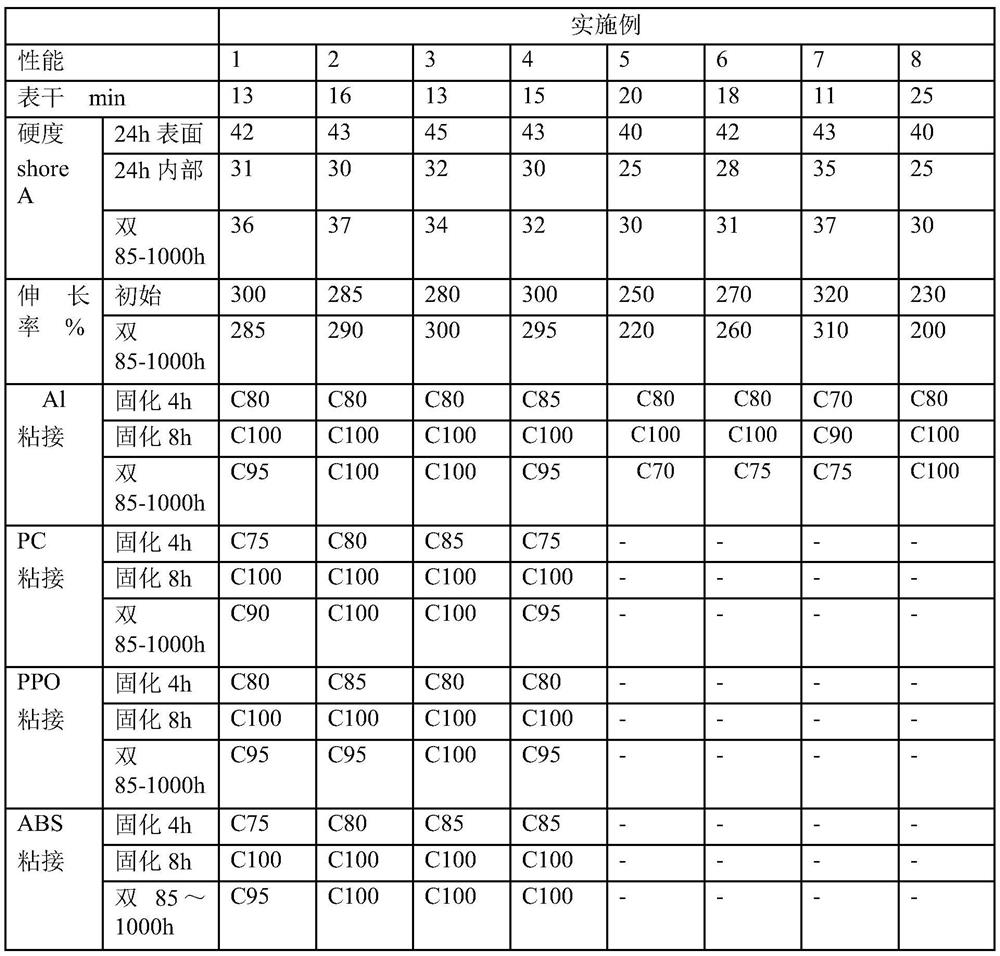

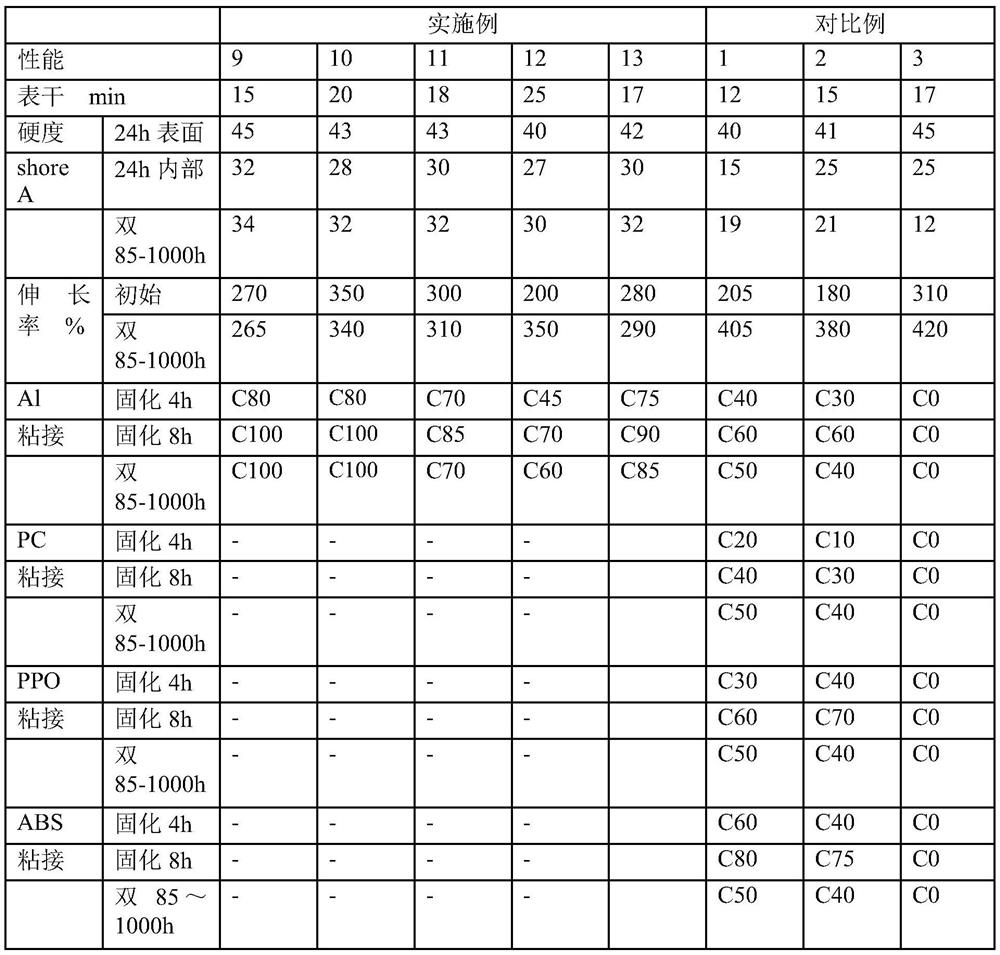

[0094] The above catalytic crosslinking agent (second component) is mixed with the main agent A1 (first component), and mixed evenly according to the weight ratio of catalytic crosslinking agent / main agent of 1:10, and the performance of the two-component silicone rubber is tested. The test data As in Table 1.

Embodiment 2

[0096] (1) Preparation of the second component

[0097] 100 parts of 1000cp methyl silicone oil, 20 parts of fumed silica treated with hexamethyldisilazane, 10 parts of titanium dioxide, 25 parts of methyltriethoxysilane, 25 parts of XL-1, and 25 parts of P-2 25 parts, 0.3 part of dibutyltin dilaurate, and mix uniformly in a planetary stirring tank.

[0098] (2) Preparation of two-component condensation type silicone adhesive

[0099] The above catalytic crosslinking agent (second component) is mixed with the main agent A1 (first component), and mixed evenly according to the weight ratio of catalytic crosslinking agent / main agent of 1:10, and the performance of the two-component silicone rubber is tested. The test data As in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com