Laser cladding self-adjusting device and method

A laser cladding and self-adjusting technology, which is applied in the coating process of metal materials, coating, etc., can solve the problems of different material utilization rates, the inability to ensure a constant distance between the cladding head and the workpiece, and constant cladding layer thickness, which hinders laser melting. Covering technical development and other issues, to achieve the effect of maintaining a stable distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

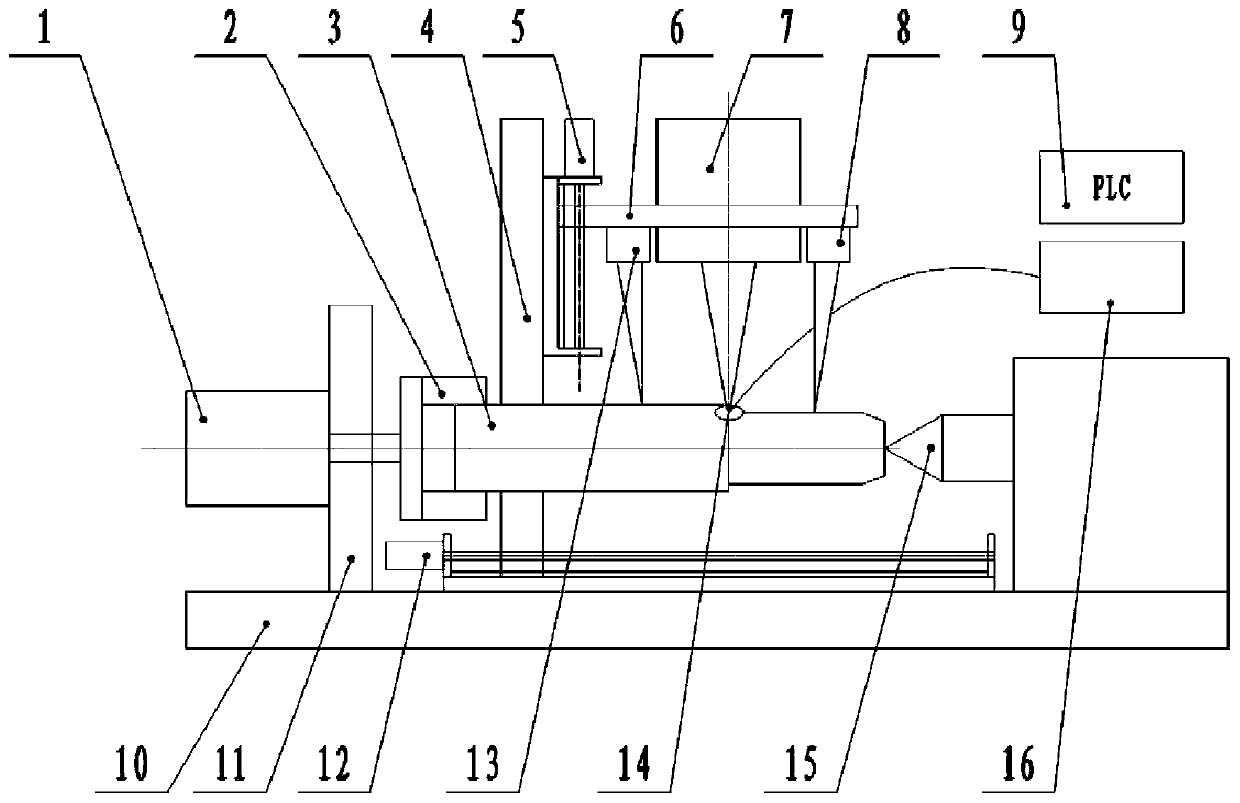

[0044] In this embodiment, the laser cladding self-adjusting device according to the present invention is used to adjust the fixed height and equal thickness of the shaft workpiece during the laser cladding process. The shaft workpiece is a cylindrical workpiece, and the workpiece 3 is clamped first. Between the chuck 2 and the tailstock 15, the laser cladding head 7 and the first distance measuring sensor 8 and the second distance measuring sensor 13 are installed on figure 1 location shown.

[0045] Before starting the cladding work in this example, set the thickness of the cladding layer and the fixed height distance between the cladding head and the workpiece, and set the Z and X axis feed speed and the workpiece rotation speed and other parameters, and then the workpiece 3 is driven by the spindle motor 1 Drive to rotate at a preset speed, the Z-axis module 5 moves from top to bottom, the first transmission distance sensor 8 detects the distance, and starts laser cladding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com