Existing pile foundation strengthening method based on grout control

A pile foundation and slurry technology, which is applied in the repair of foundation structures, sheet pile walls, foundation structure engineering, etc., can solve the problems of limited reinforcement performance, waste of slurry, and difficulty in control, so as to improve the efficiency of grouting and reduce the output of slurry. , the effect of avoiding uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

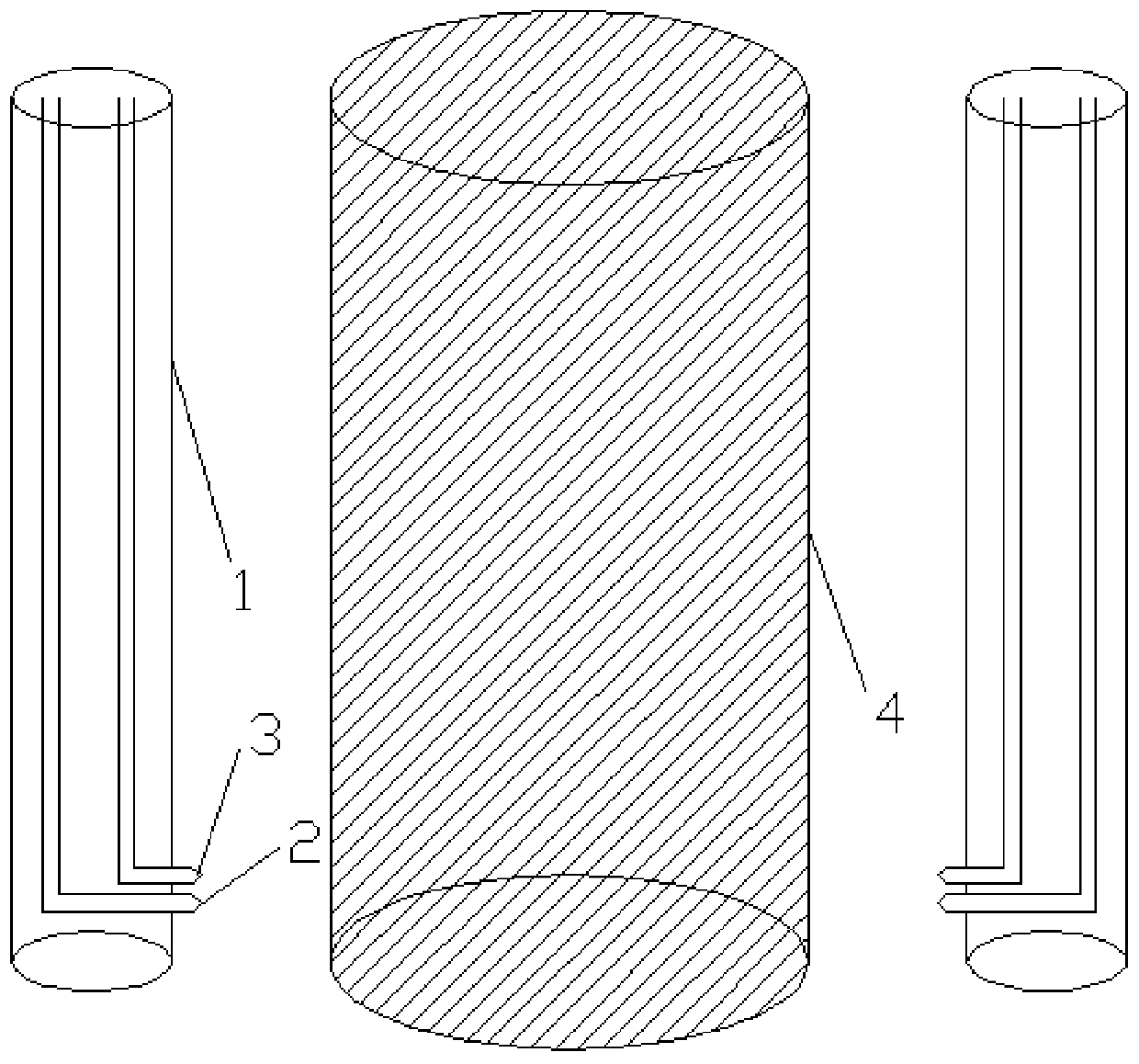

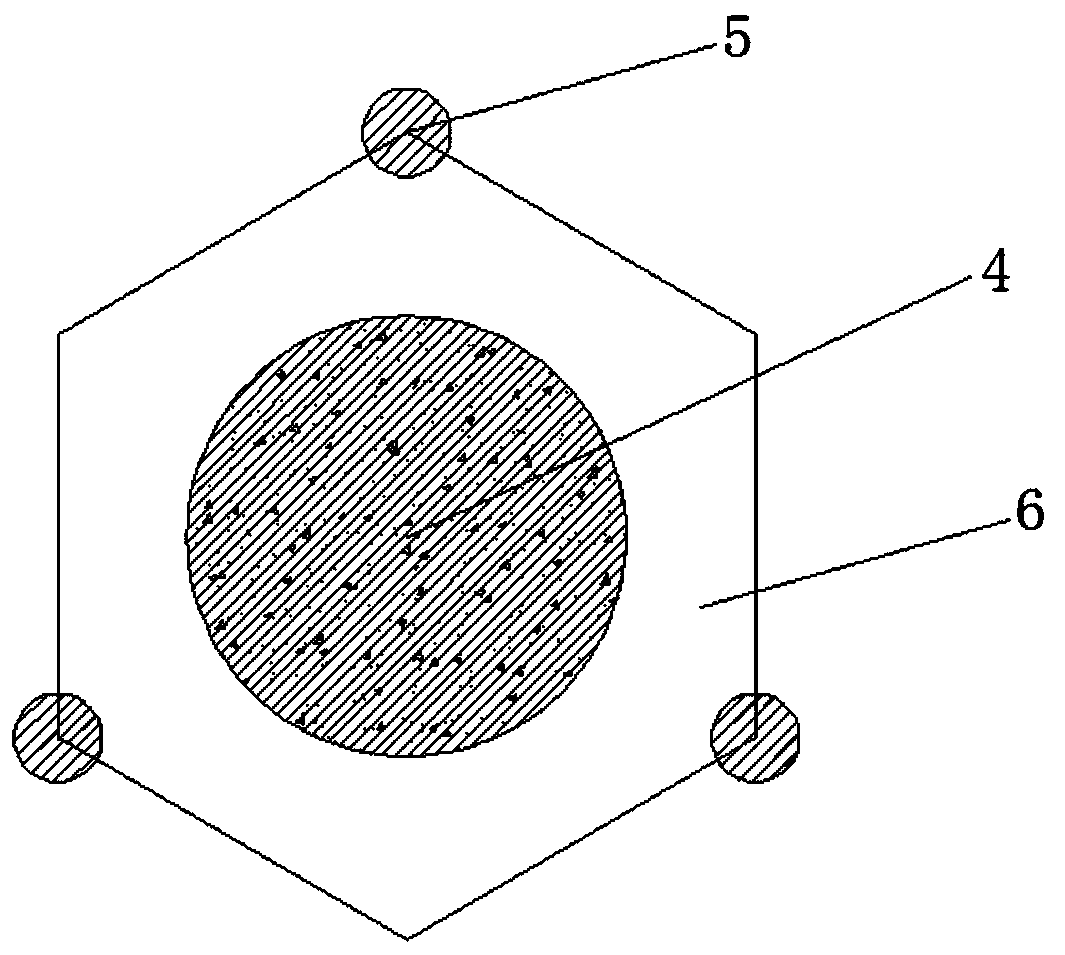

[0035] In a typical implementation of the present disclosure, such as Figure 1-Figure 2 As shown, a method of strengthening existing pile foundations based on grout control is proposed.

[0036] Determine the pile foundation 4 that needs to be reinforced, determine the reinforcement range of the pile foundation according to the engineering requirements, drill a plurality of boreholes 5 around the existing pile foundation according to the reinforcement range, and lower the double pipe 1 into the borehole;

[0037] A corresponding water injection nozzle 2 and a grouting head 3 are arranged at the bottom of the double pipe, the water injection nozzle is connected to the high-pressure water supply end through the water injection pipeline, and the grouting head is connected to the slurry supply end through the grouting pipeline;

[0038] The grouting reinforcement process of each borehole is divided into multiple sections, and each section is subjected to water injection disturban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com