Bamboo plywood shear wall

A bamboo plywood and shear wall technology, which is applied to walls, building components, buildings, etc., can solve the problems of low seismic performance of bamboo plywood shear walls, avoid nail pull-out damage, avoid board edge tearing, The effect of improving the shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

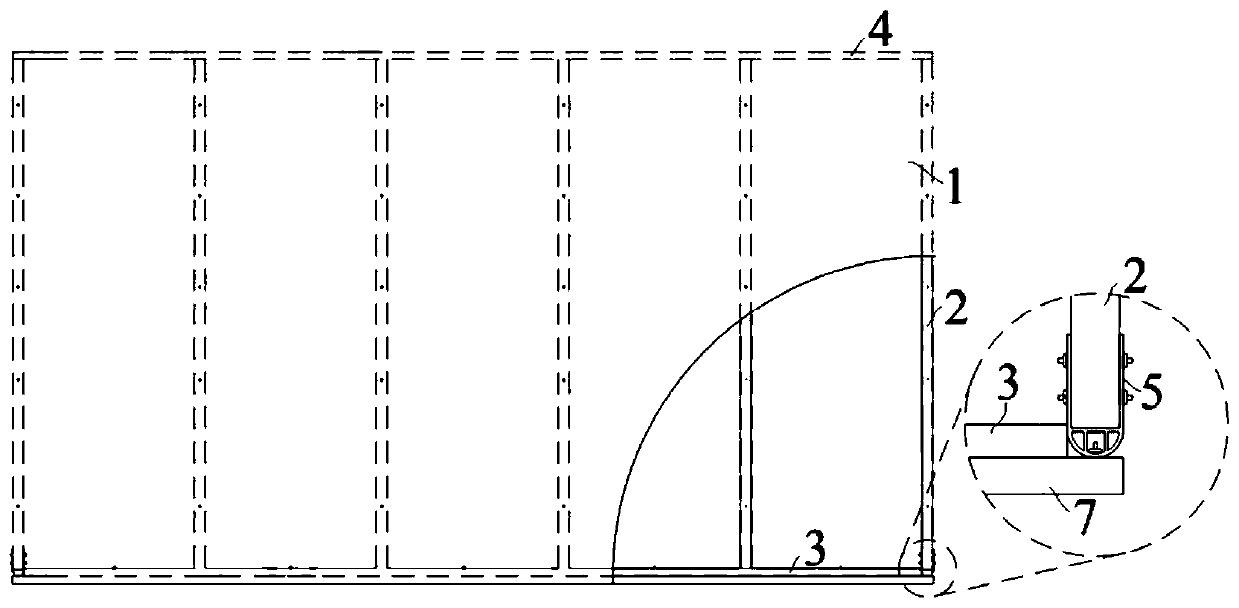

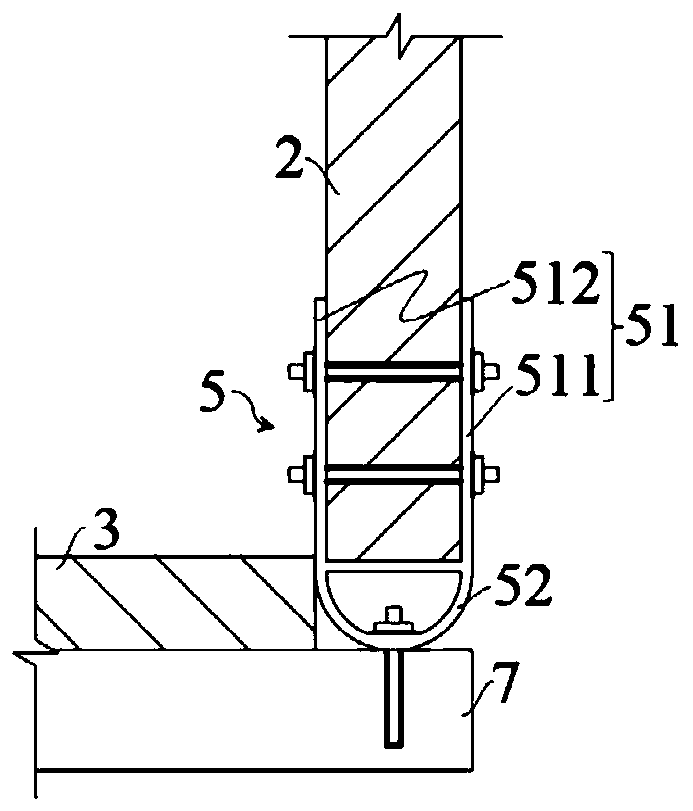

[0044] refer to figure 1, In this embodiment, the bamboo plywood shear wall includes a bottom beam plate 3 and a top beam plate 4 arranged parallel to each other, and a plurality of stud columns 2 are arranged between the bottom beam plate 3 and the top beam plate 4 . The studs 2 are parallel to each other, and the plurality of studs 2 specifically include the studs 2 at the ends near the two sides of the bottom beam plate 3, and the other studs 2 at the two ends. The stud column 2 on the inner side of the bottom beam plate 3 between.

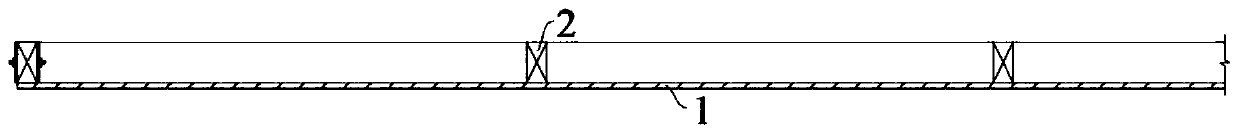

[0045] refer to figure 2 , There is also a bamboo plywood 1 between the bottom beam plate 3 and the top beam plate 4, and the bamboo plywood 1 is connected to the stud column 2. Specifically, the shape of the bamboo plywood 1 corresponds to the shape surrounded by the bottom beam 3, the top beam 4 and the stud column 2 at the end, that is, the upper and lower edges of the bamboo plywood 1 are in contact with the top beam 4 and the bottom. T...

Embodiment 2

[0055] refer to Figure 5 , in this embodiment, the bamboo plywood shear wall is also provided with two layers of gypsum boards 6 on both sides of the bamboo plywood 1, forming a bamboo plywood shear wall with a composite structure, thereby increasing the overall stability of the shear wall and beautify its appearance.

[0056] Specifically, refer to Figure 6 , the bottom beam board 3 and the top beam board 4 of the present embodiment are provided with two layers of gypsum boards 6, a layer of bamboo plywood 1 is arranged between the two layers of gypsum boards 6, and the two layers of gypsum boards 6 and the bamboo plywood 1 are arranged parallel to each other . A plurality of studs 2 are arranged in parallel between the gypsum board 6 and the bamboo plywood 1, and the positions of the studs 2 on both sides of the bamboo plywood 1 are corresponding, that is, the bamboo plywood 1 is sandwiched between two rows of studs 2 and are connected with two rows of stud columns 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com