Experimental device and method of application of capillary tube with covering pressure

An experimental device and technology for thin tubes, which are used in earth-moving drilling, wellbore/well components, measurement, etc., can solve problems such as the limited lower limit of sand filling permeability in thin tubes, no consideration of overburden, and inability to consider sand cementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below according to the accompanying drawings and examples, so that those skilled in the art can understand the present invention. However, it should be clear that the present invention is not limited to the scope of specific embodiments. For those of ordinary skill in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all within the scope of protection. List.

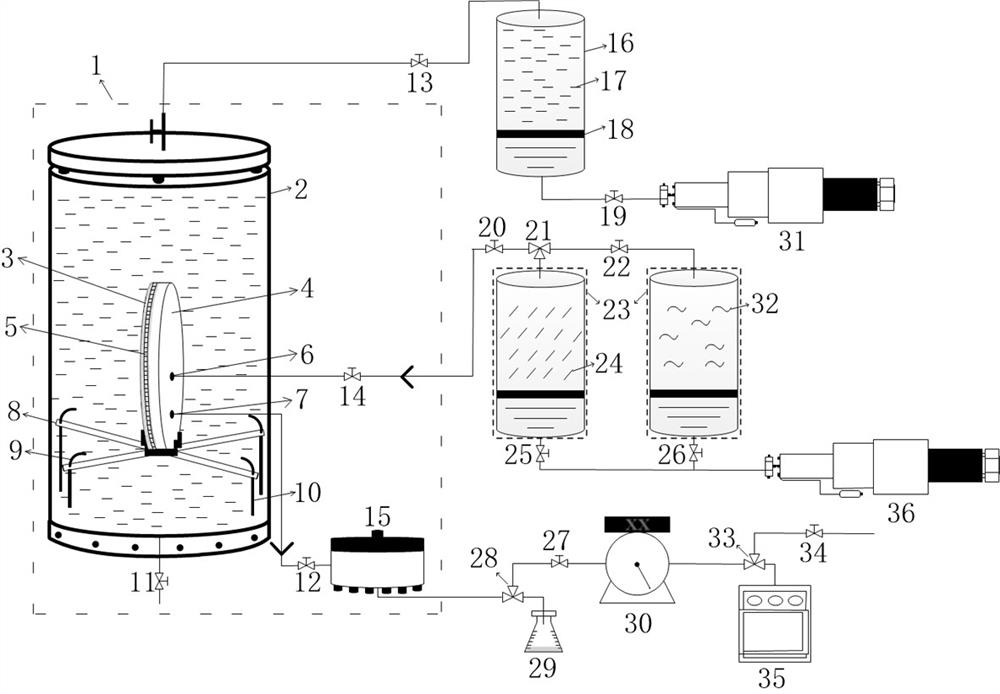

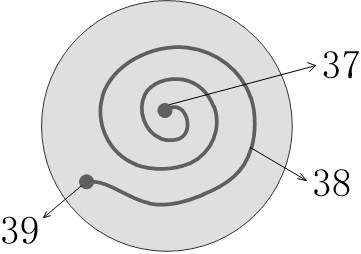

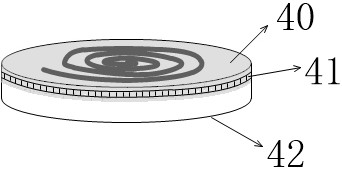

[0033] see figure 1 , figure 2 , Figure 4 .

[0034] A capillary experimental device with pressure covering is composed of a high and low temperature test chamber 1, an autoclave 2, a capillary column 4, a rubber sheath 3, a fluid injection system and a fluid extraction system.

[0035] The autoclave 2 is placed in the high and low temperature test chamber 1, and the autoclave is connected with an intermediate container 16 and a displacement pump 31, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com