Fault diagnosis method for through-flow part of steam turbine based on thermal parameters

A technology of flow parts and thermal parameters, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as poor sensitivity to direct thermal parameter changes, inability to detect changes in unit performance in time, and delay in response, and achieve accuracy. High, simple method, simple system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

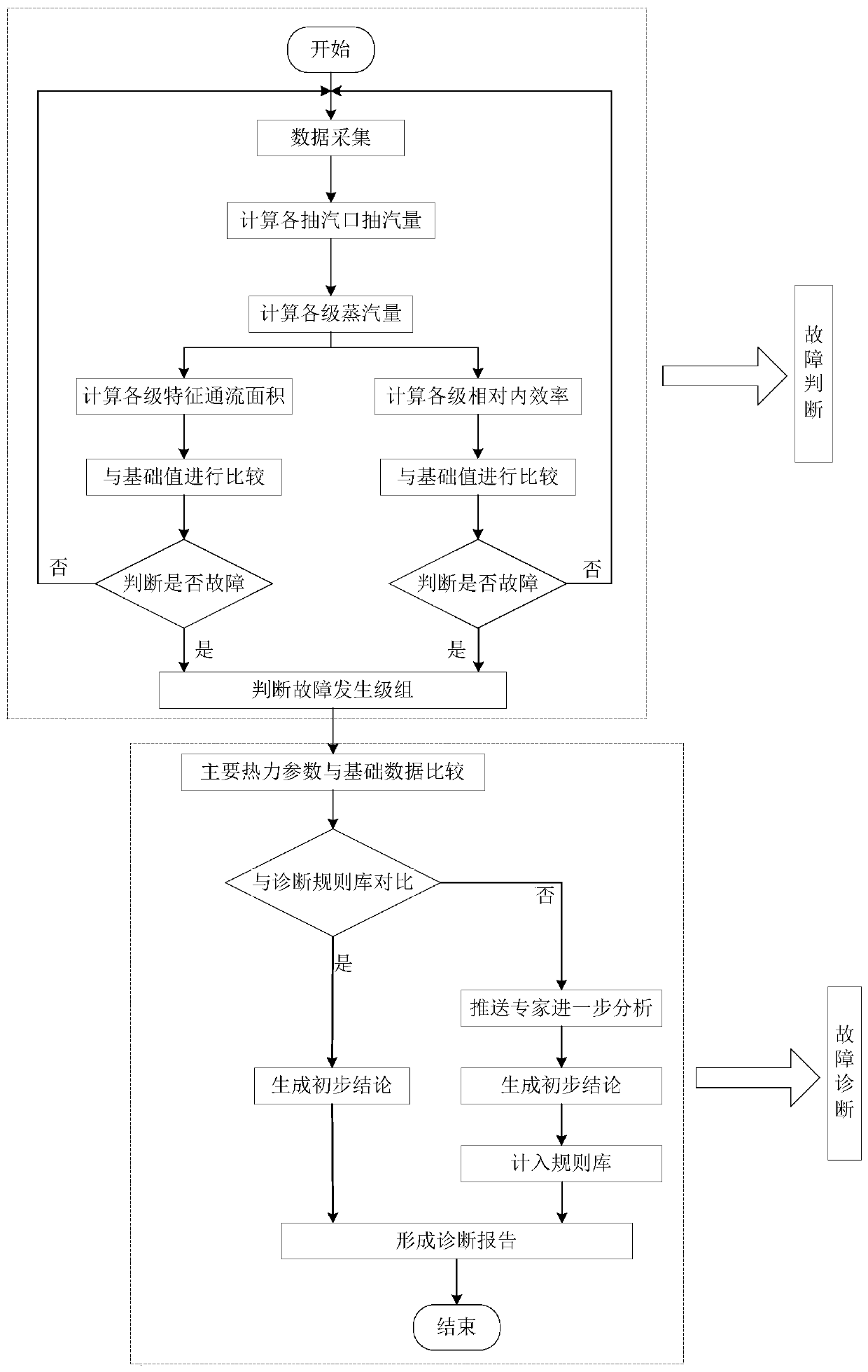

[0022] see figure 1 , the present invention comprises the following steps:

[0023] Step 1. Real-time collection of various parameters in the operation of the steam turbine, including the pressure and temperature of each level group and each extraction port, the pressure and temperature of the inlet and outlet of the heater, the drain temperature and the main condensate flow rate, and use the "Water and Water Vapor Properties" calculates the enthalpy and entropy values of steam and water;

[0024] Step 2, according to the pressure of each steam leakage point, the functional relationship between the flow rate of each steam leakage point and the pressure of the steam leakage point is established;

[0025] Step 3, calculating the steam extraction volume of each steam extraction port through heat balance;

[0026] Step 4, calculate the characteristic flow area of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com