Display backboard, manufacturing method thereof and display device

A display backplane and substrate substrate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of long time-consuming display backplane, photoresist residue, and display backplane needing improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

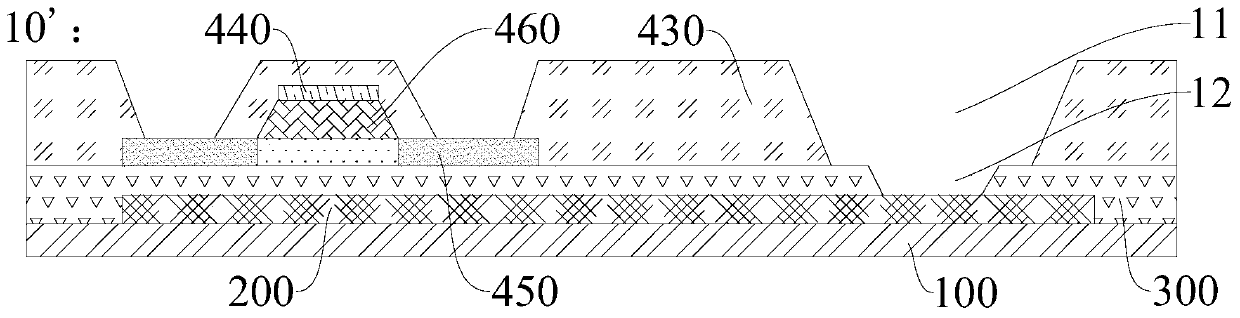

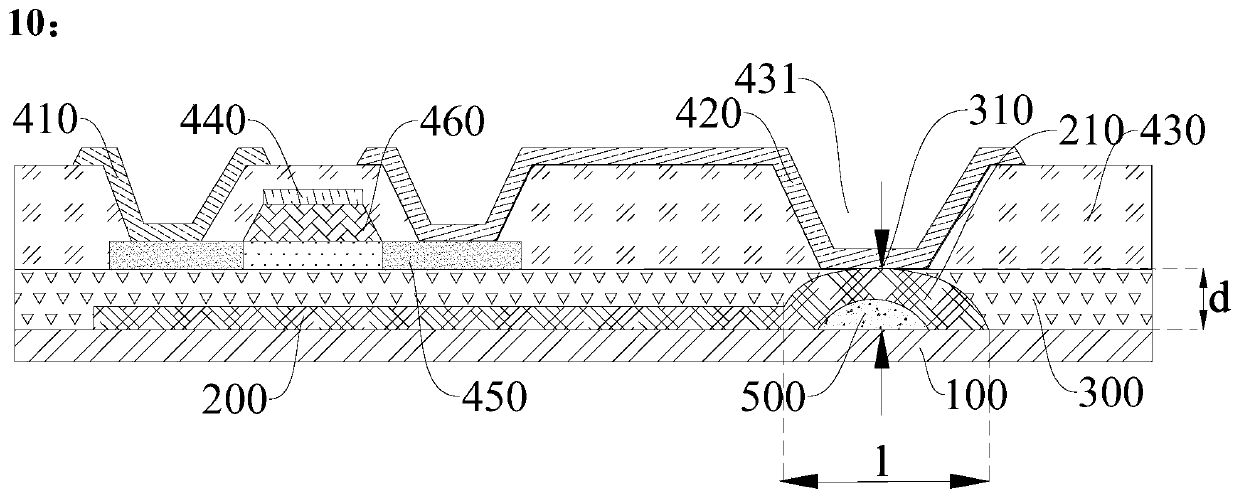

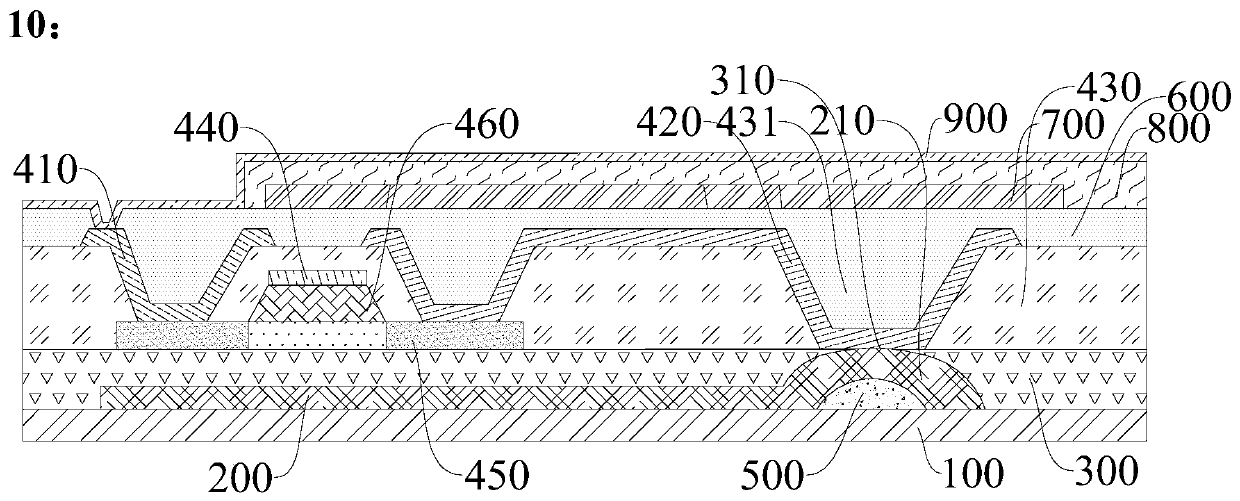

[0025] The present invention is accomplished based on the following findings of the inventors:

[0026] In related technologies, the inventors have conducted in-depth investigations and a large number of experimental verifications on the reasons why the manufacturing process of the display backplane takes a long time, the production efficiency is low, the display quality of the display device assembled into it is low, and the display effect is not good. , in the manufacturing process of the display backplane of the related art, it is difficult to etch when etching the set holes on the interlayer insulating layer and the buffer layer. Due to the difficulty of the aforementioned etching, the photolithography step requires The time is longer. On the one hand, the photoresist is more likely to be denatured during the longer etching time, so that the photoresist is not easy to be peeled off in the subsequent steps, so that photoresist residue will appear after it is assembled into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com