Swing arm motor of plate workpiece hemming device

A technology for wrapping devices and workpieces, applied in electromechanical devices, transportation and packaging, electric components, etc., can solve problems such as poor consistency of wrapping state, manual wrapping operation for leaks, and bulkiness, etc., to achieve easy mass production and overcome manual labor The effect of unreliable operation and high degree of systematization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

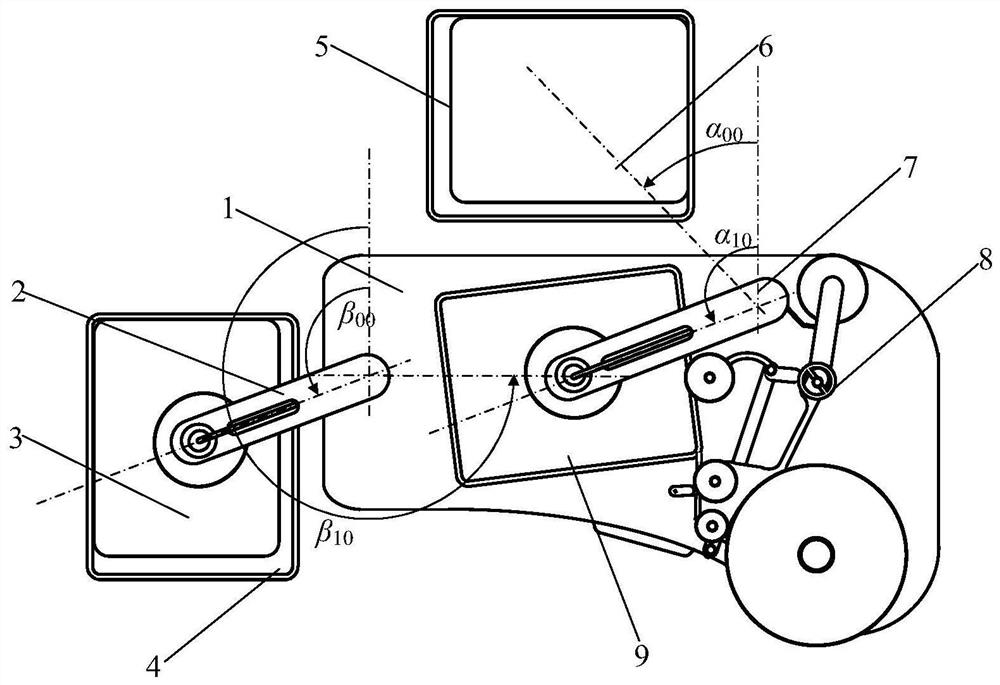

[0029] exist figure 1In one embodiment of the present invention shown—the plate-shaped workpiece hemming method top view schematic diagram: the overall configuration described in the plate-shaped workpiece hemming method includes a base 1, a blanking mechanism 2, a package, a blanking car 4, Loading cart 5, items to be packaged 6, feeding mechanism 7, belt feeding mechanism 8 and packaged items 9. Abutment 1, as the main workbench, cabinet body and work and bearing surface of the overall device of the system, is located in the middle right of the workplace. The unloading mechanism 2 is used as a system device for grasping, transferring and lowering the package, and is assembled on the left end above the abutment 1 . The packaged piece 3 is the work object of the system device—the workpiece that has been hemmed is grasped, transferred, and lowered by the unloading mechanism 2, and placed in the unloading car 4 in turn. The unloading vehicle 4 is used as a transfer device for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com