Screening system and screening method for wet powder-containing lump ore

A screening and powder block technology, which is applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of increasing the difficulty of screening powders on the sieve bed and falling onto the vibrating sieve bed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

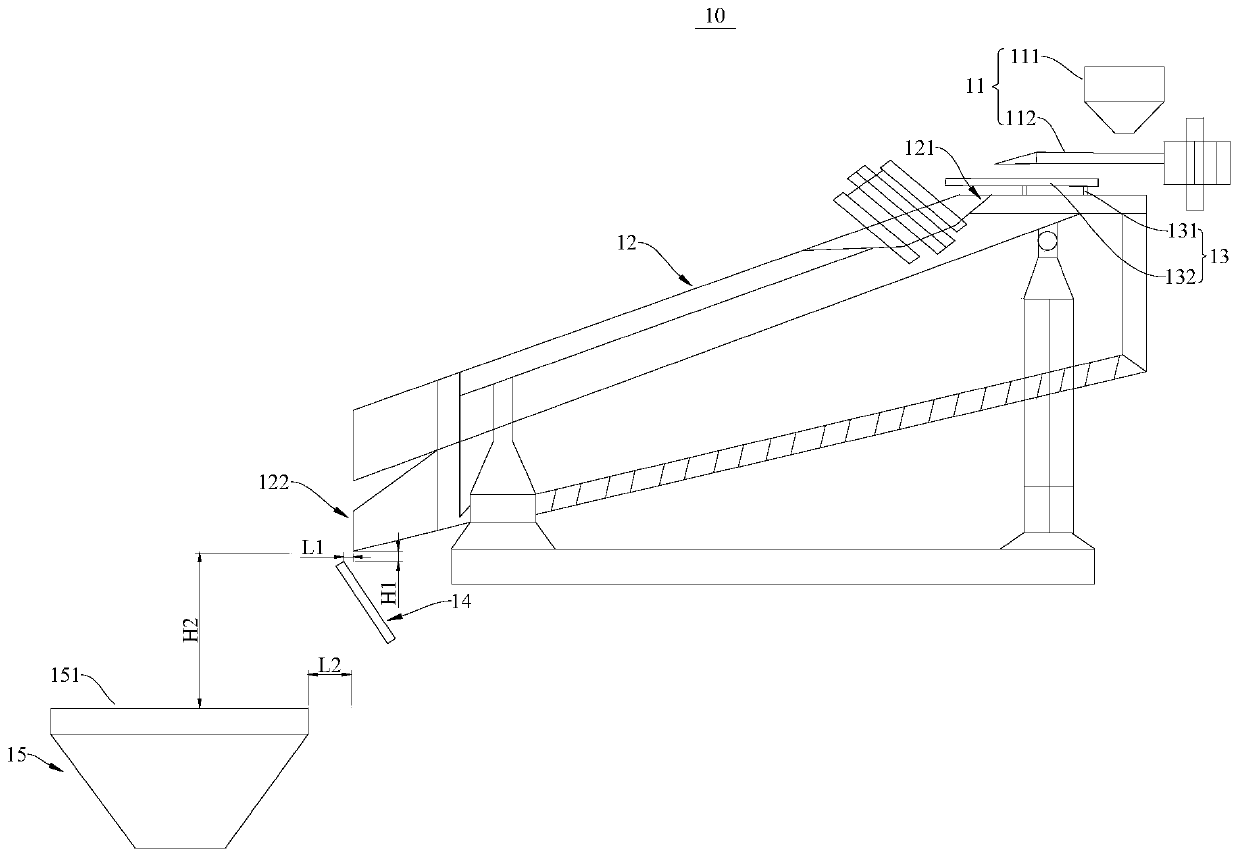

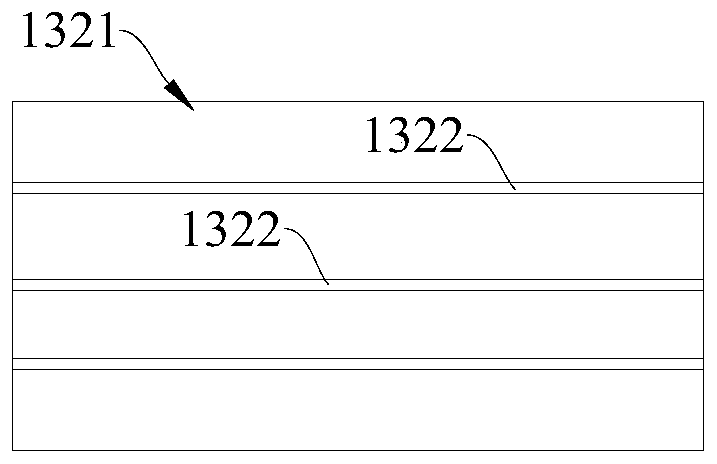

[0084] This embodiment provides a screening system 10 for wet powder-containing lump ore. The screening system 10 includes a feeder 11 , a vibrating screen 12 , a diverting mechanism 13 , a material guide trough 14 and a receiving hopper 15 . Wherein, the support plate 1321 of the flow diversion mechanism 13 is arranged horizontally, the height difference between the end of the support plate 1321 and the input end 121 of the vibrating screen 12 is 180 mm, and the end of the feed channel 14 close to the output end 122 of the vibrating screen 12 is connected to the vibrating screen 12 The height difference of the output end 122 is 12mm, the horizontal distance between the first dead center and the output end 122 of the vibrating screen 12 is 20mm, the inclination angle of the vibrating screen 12 is 26 °, the top of the receiving hopper 15 and the output end 122 of the vibrating screen 12 The height difference is 500mm, and the horizontal distance between the edge of the output en...

Embodiment 2

[0087] This embodiment provides a screening system 10 for wet powder-containing lump ore. The screening system 10 includes a feeder 11 , a vibrating screen 12 , a diverting mechanism 13 , a material guide trough 14 and a receiving hopper 15 . Wherein, the support plate 1321 of the flow diversion mechanism 13 is arranged horizontally, the height difference between the end of the support plate 1321 and the input end 121 of the vibrating screen 12 is 180 mm, and the end of the feed channel 14 close to the output end 122 of the vibrating screen 12 is connected to the vibrating screen 12 The height difference of the output end 122 is 10mm, the horizontal distance between the first dead center and the output end 122 of the vibrating screen 12 is 15mm, the inclination angle of the vibrating screen 12 is 20°, the top of the receiving hopper 15 and the output end 122 of the vibrating screen 12 The height difference is 500mm, and the horizontal distance between the edge of the output end...

Embodiment 3

[0090] This embodiment provides a screening system 10 and a screening method for wet powder-containing lump ore. The screening system 10 is basically the same as the screening system 10 in Embodiment 1, except that the first dead point is the same as that of the vibrating screen. The horizontal distance of the output end 122 of 12 is 25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com