Auxiliary shape rectification welding tool for circular ring part quick clamping

A technology for welding tooling and ring parts, which is applied in the field of rapid clamping and auxiliary orthopedic welding tooling for ring parts, can solve the problems of poor stability, poor adaptability of products with different diameters, and large size adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

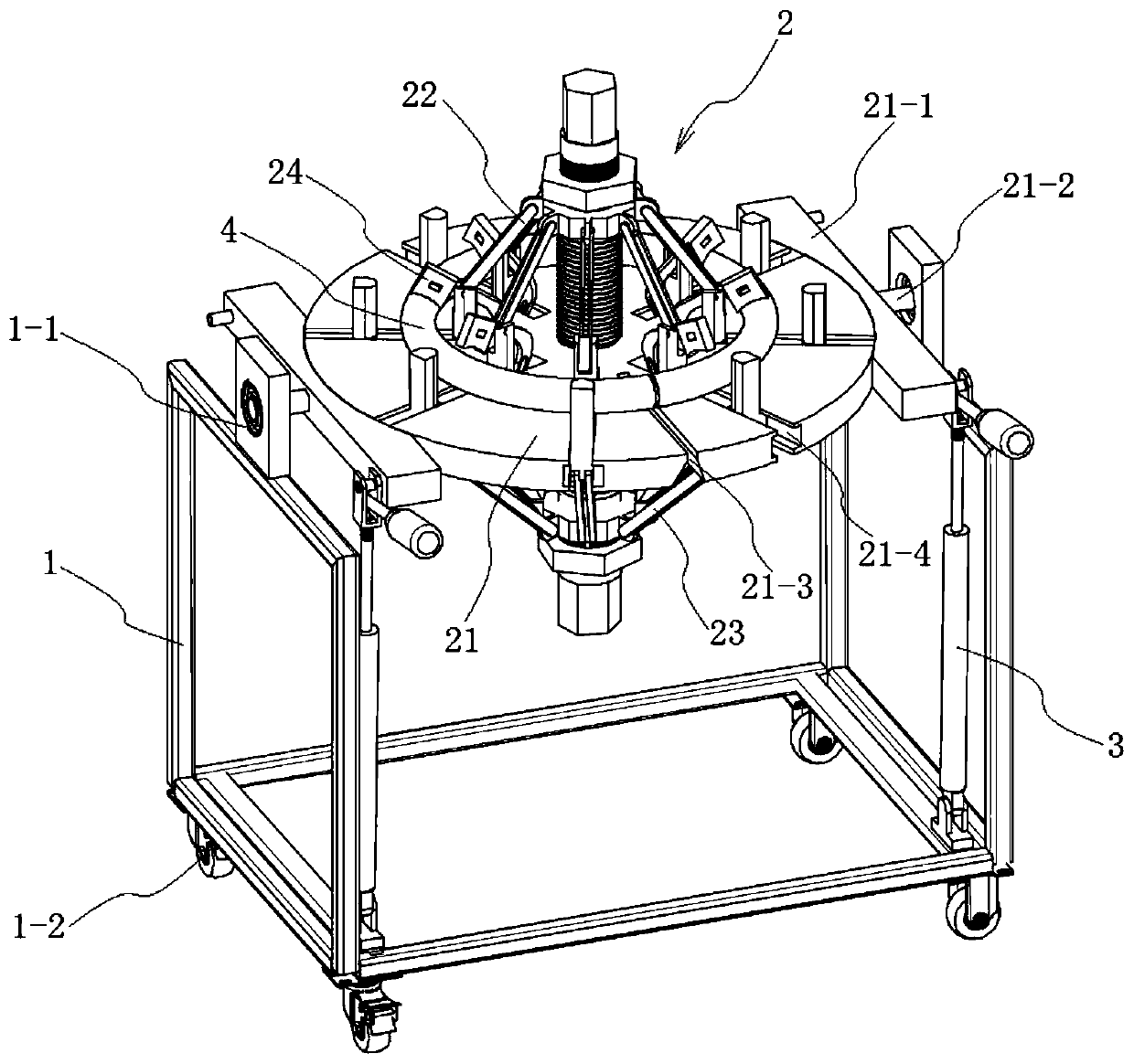

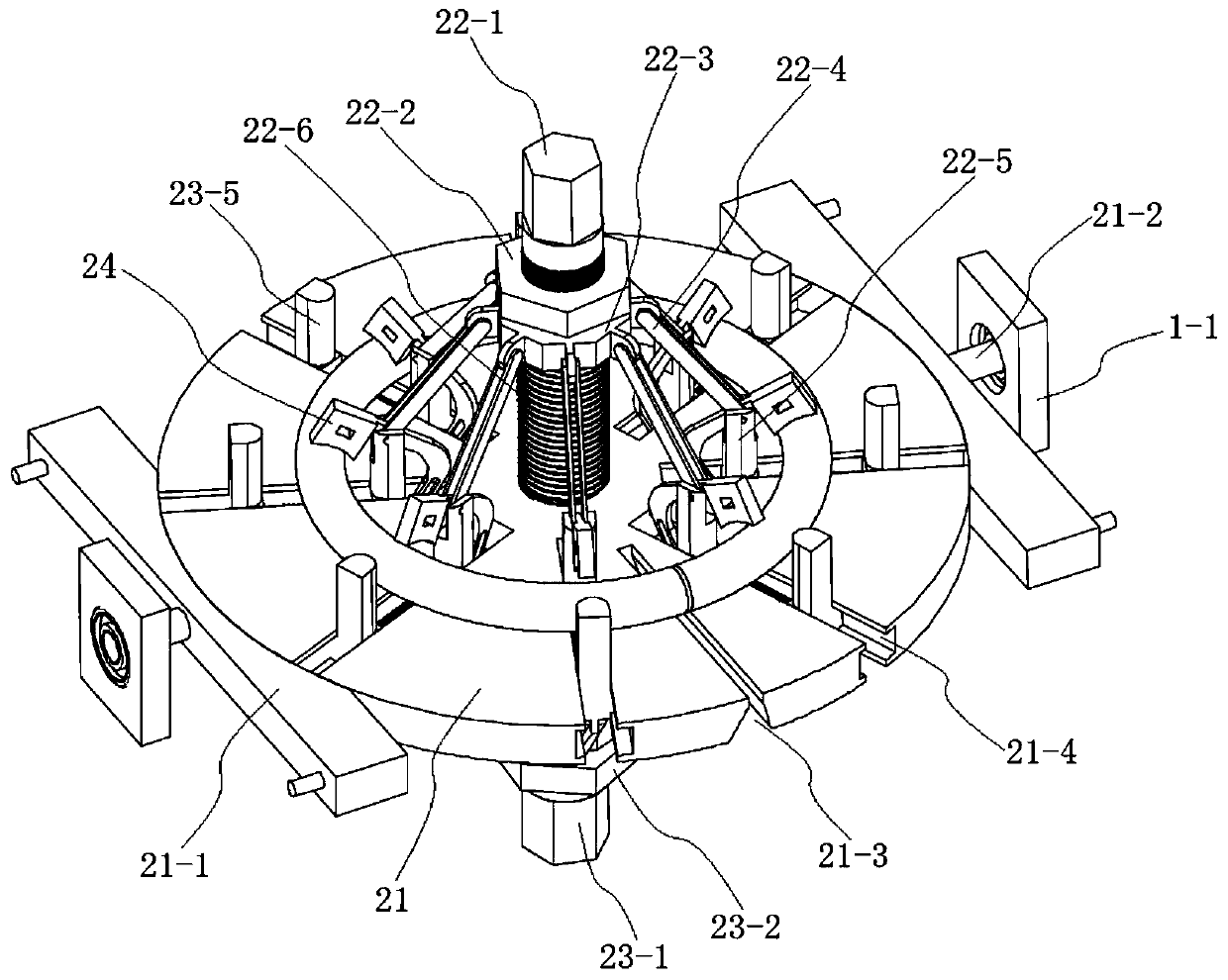

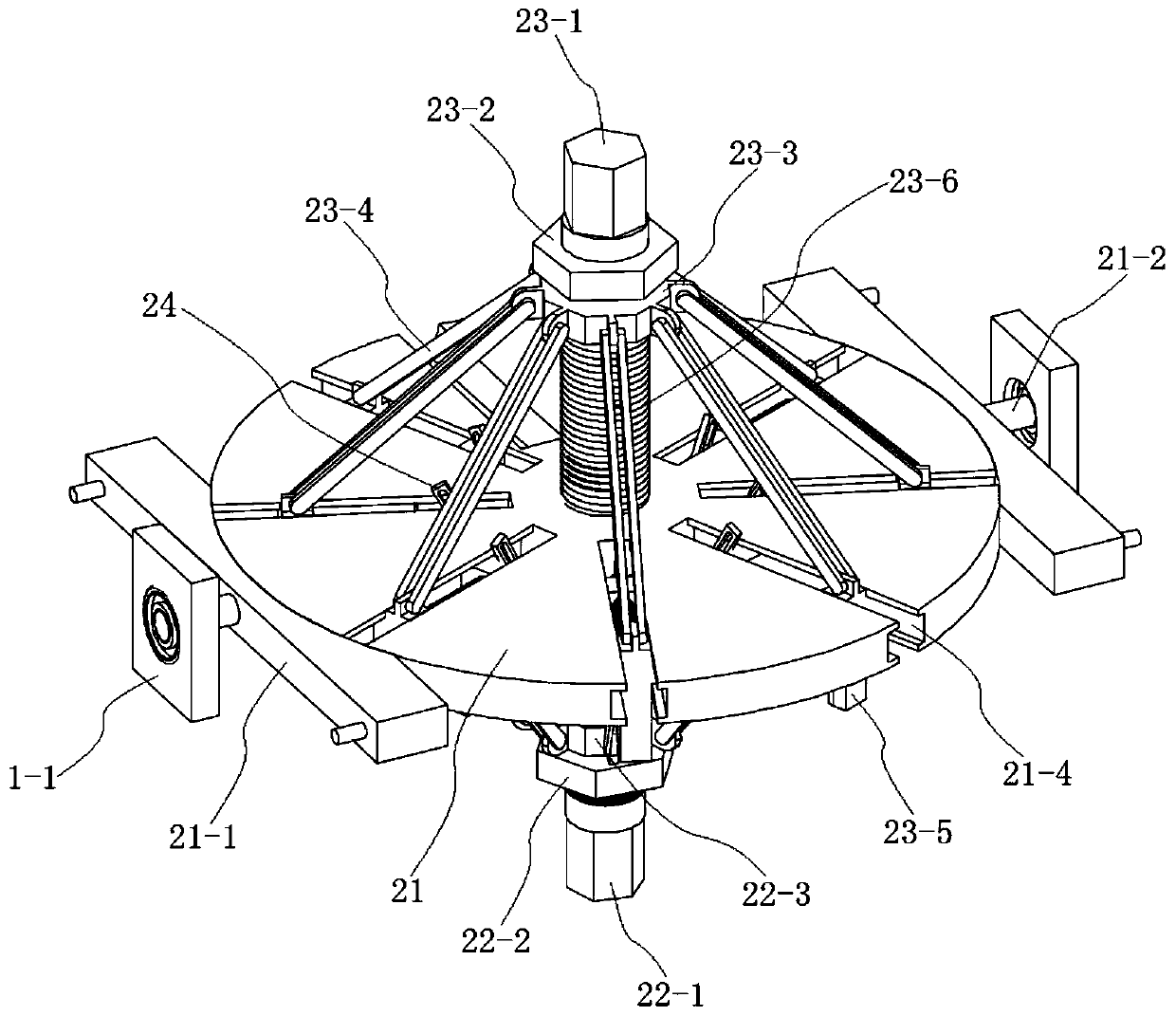

[0037] combine figure 1 , figure 2 and image 3 As shown, a kind of circular ring fast clamping auxiliary orthopedic welding tool in this embodiment includes a bracket 1 and an orthopedic fixing device 2 rotatably erected on the bracket 1. The orthopedic fixing device 2 can be rotated on the bracket 1 so as to facilitate the Preliminary welding and fixing are performed on both sides of the clamped ring member 4 to facilitate subsequent full welding operations. in:

[0038] The orthopedic fixing device 2 comprises a base 21, an inner wall positioning mechanism 22, an outer wall positioning mechanism 23 and a pressing mechanism 24. The base 21 is a disc-shaped structure, and the base 21 is evenly provided with some radially arranged slides along the circumferential direction. The groove 21-4 and at least one radially disposed welding opening 21-3 are provided on the base 21, and the back of the reversed orthopedic fixing device 2 can be welded by using the welding opening 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com