Device and method for cutting explosive cartridge

A medicine rolling and cutting technology, applied in metal processing and other directions, can solve the problems of dangerous and inconvenient operation, flying stones, pollution and waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

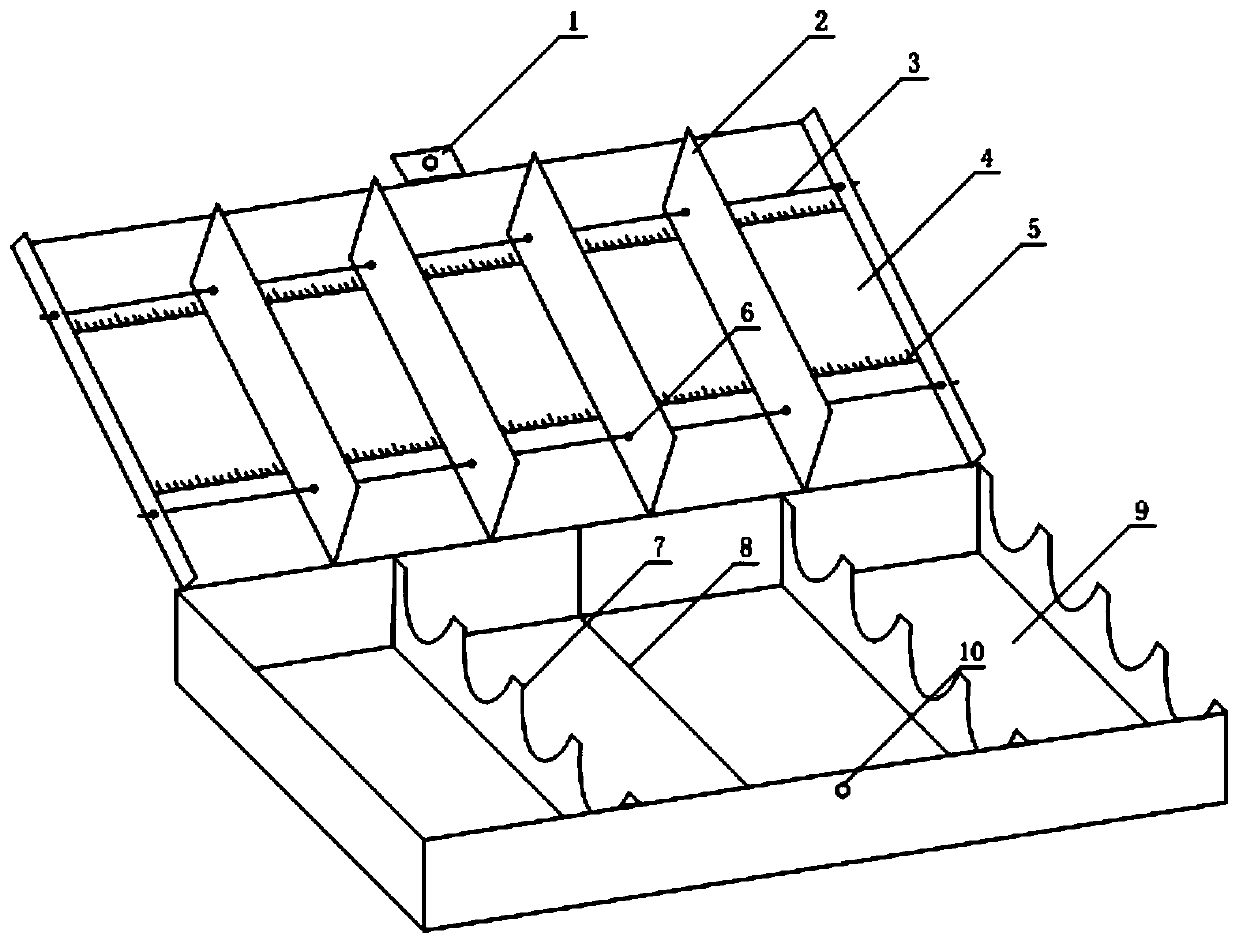

[0035] like Figure 1-3 As shown, this embodiment provides an explosive charge coil cutting device, which is mainly composed of a blade plate 4, a charge coil placing plate 9, an operating handle 1, a buckle 10 and a clamping hole 11. The buckle 10 and the clamping hole 11 can be Close and fasten to ensure safe operation and storage.

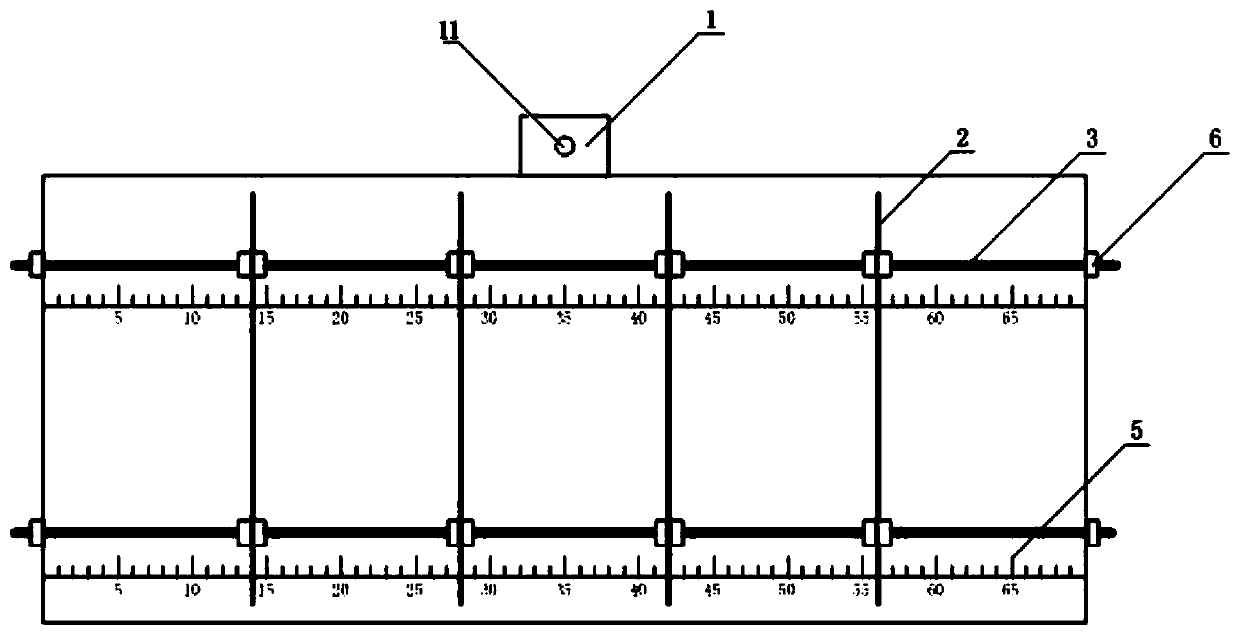

[0036] In this specific embodiment, as figure 1 and 3 As shown, the blade disc 4 is mainly composed of a blade 2, a lead screw 3, an adjusting nut 6 and a scale 5. The blade 2 can be flexibly mounted and dismounted, accurately positioned and reliably fixed, and distributed according to the required explosive length, and can be accurately cut Dynamite rolls.

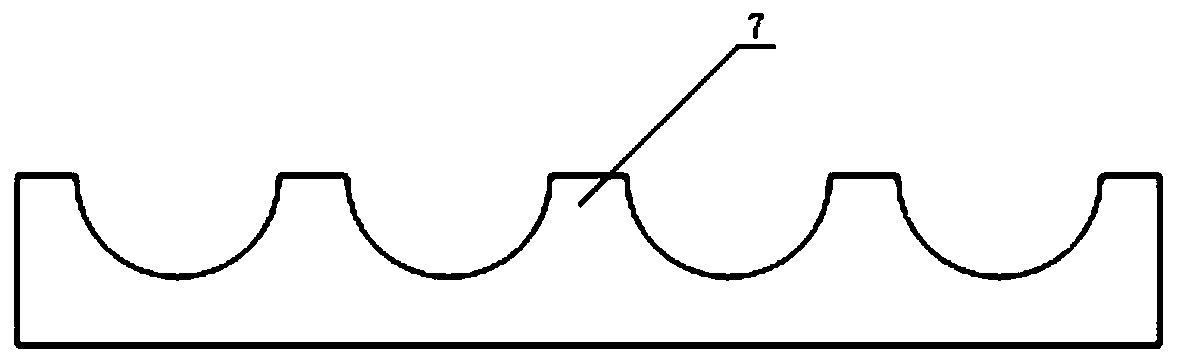

[0037] In this specific embodiment, as figure 1 and 2 As shown, the medicine roll placing tray 9 is mainly composed of a card slot 8 and a medicine roll support 7, and the medicine roll support 7 can be flexibly installed according to the required number.

[0038] Below is a descripti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com