An automatic packaging device for goggles

A technology of automatic packaging and goggles, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of lens surface damage, poor product packaging consistency, low packaging efficiency, etc., to improve production efficiency, improve production efficiency, reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

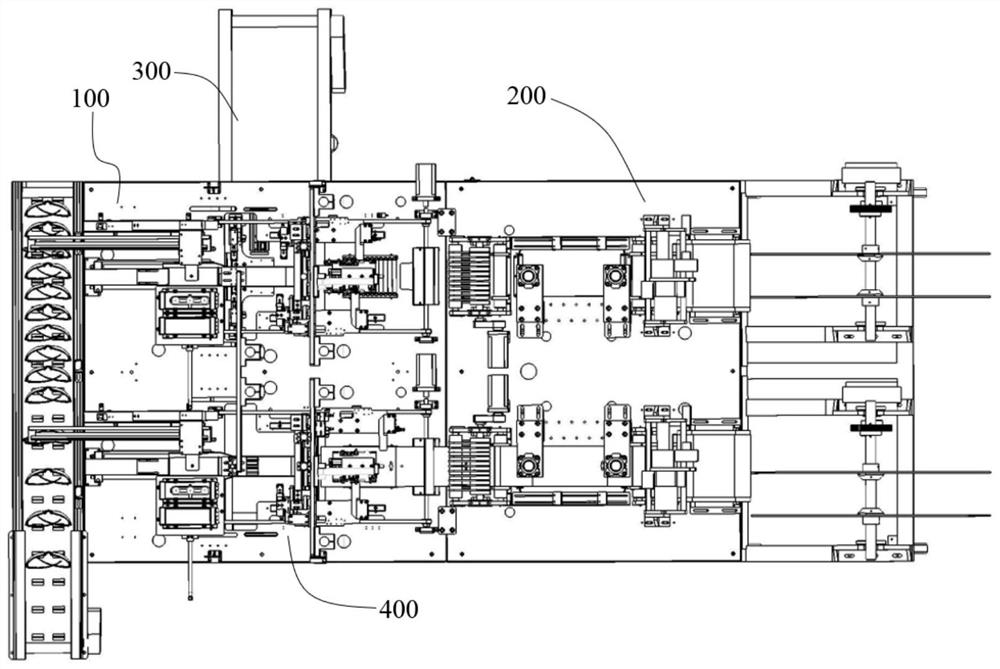

[0035] Specific implementation mode one: as Figure 1-11 As shown, the automatic packaging device for goggles of the present embodiment includes a feeding module 100, a bag feeding module 200, a packaging module 300 and a finished product discharging module 400, the feeding module 100 and the bag feeding module 200 are located on the same straight line, and the packaging module 300 And the finished product discharging module 400 is located between the feeding module 100 and the bag feeding module 200;

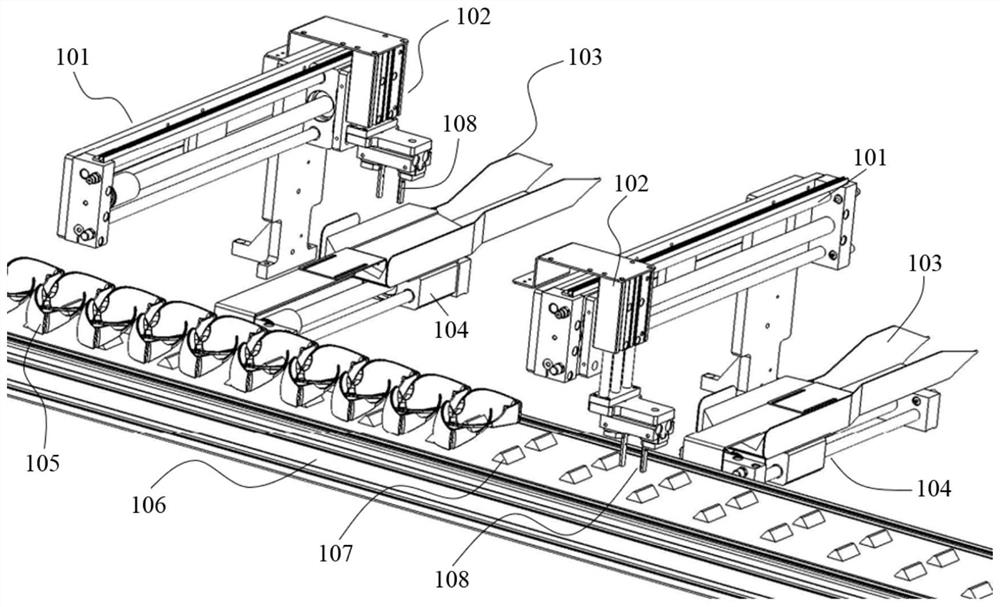

[0036] The feeding module 100 includes a feeding conveyor belt 106, a retrieving mechanism and a telescopic hopper. The retrieving mechanism includes a mirror-taking air claw 108, a traverse cylinder 101 and a lifting cylinder 102. The mirror-taking air claw 108 is installed on the sliding seat of the lifting cylinder 102 , the lifting cylinder 102 is installed on the sliding seat of the traversing cylinder 101, the telescopic hopper includes the sliding table cylinder 104 and ...

specific Embodiment approach 2

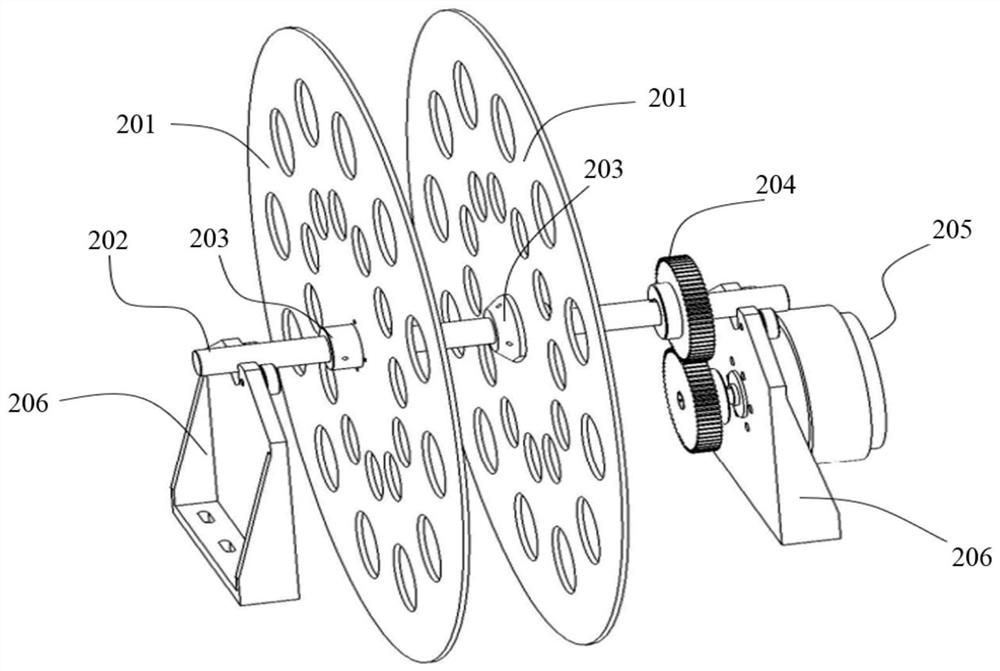

[0043] Specific implementation mode two: as Figure 4 As shown, the bag pulling mechanism in this embodiment includes a pressing plate 216, a first servo motor 212, two slotted rubber rollers 213, several hook springs 211, two roller shafts 210 and a plurality of guide shafts 215, two slotted The rubber roller 213 is set up and down close to each other. The grooved rubber roller 213 is processed with several annular grooves along its length direction. The two roller shafts 210 are arranged correspondingly up and down. A plurality of hook springs 211 are installed on the top, and the hook springs 211 are clamped on the corresponding annular grooves. One of the two grooved rubber rollers 213 is driven by the first servo motor 212, and one side of the grooved rubber rollers 213 is sequentially A guide shaft 215, three guide shafts 215 and a pressing plate 216 are provided, and the plastic packaging bag is successively installed on the pressing plate 216, three guiding shafts 215,...

specific Embodiment approach 3

[0046] Specific implementation mode three: as Figure 4 As shown, the punching mechanism in this embodiment includes a punching collection box 217 and two punching cylinders 214, the two punching cylinders 214 are arranged between one guide shaft 215 and three guide shafts 215 at intervals, and the two punching cylinders Just below 214 is provided with punching material collection box 217.

[0047] With such a design, the plastic packaging bag can be punched.

[0048] Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com