Clean incinerator

An incinerator and clean technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of large environmental pollution, low combustion efficiency, and high content of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

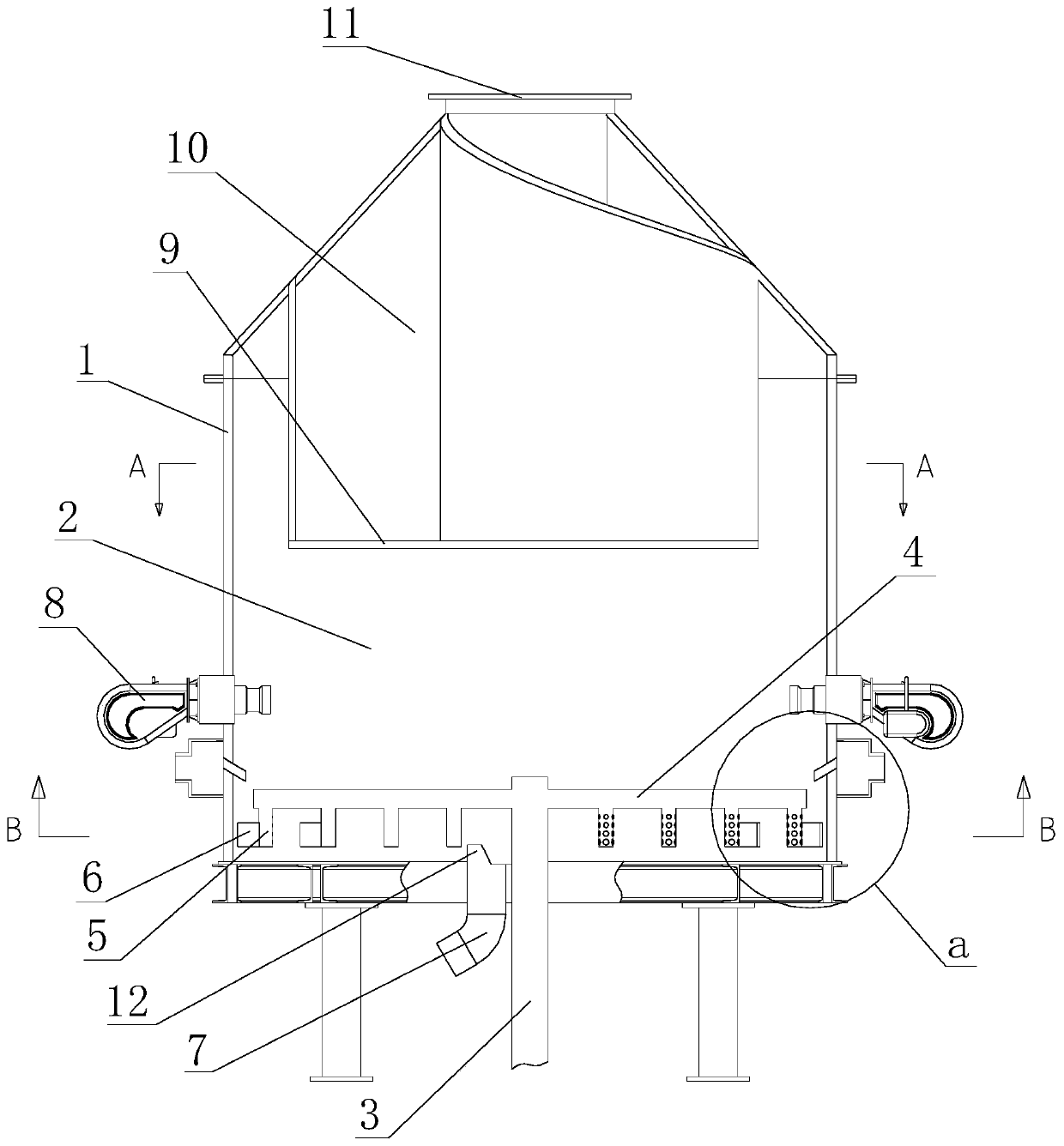

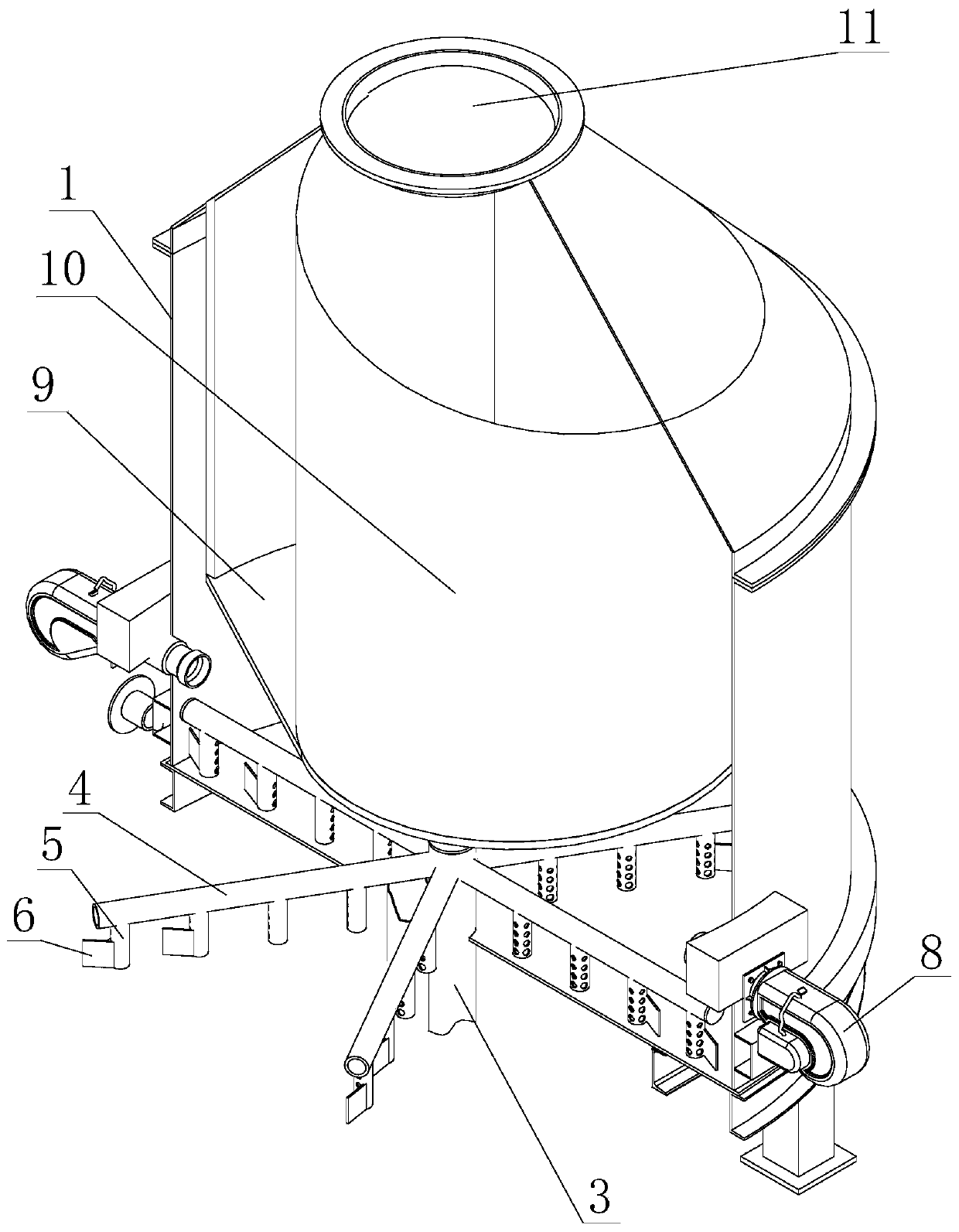

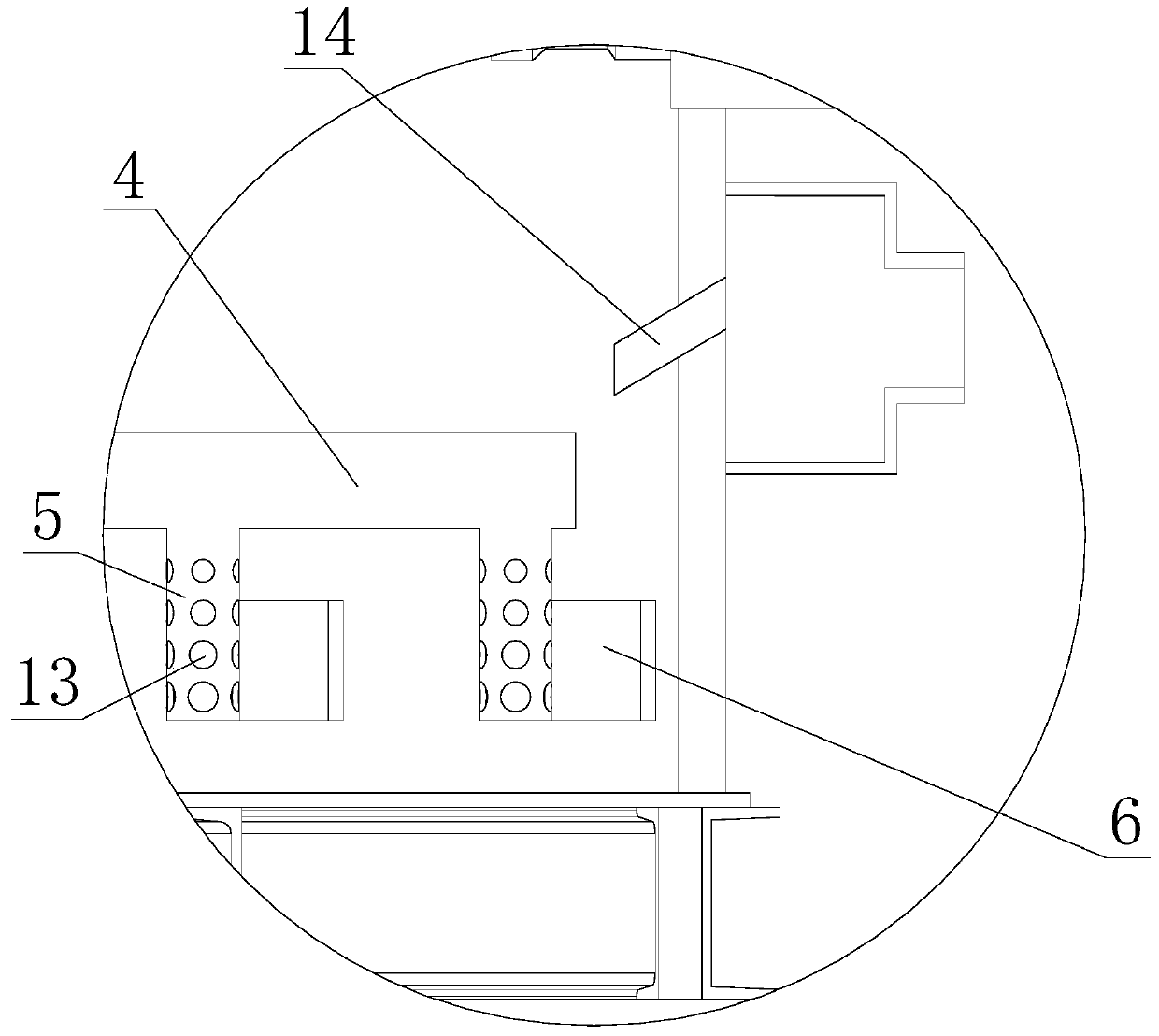

[0027] Such as Figure 1 to Figure 6 As shown, a clean incinerator includes a body of furnace 1. The body of furnace 1 is a double-layer structure. The outer layer of the furnace body 1 is an iron sheet, and the inner layer of the furnace body 1 is an insulating layer. The insulation layer is made of high alumina bricks, insulation bricks and insulation castables. A furnace 2 is arranged inside the furnace body 1 . A vertically arranged rotary shaft 3 is arranged at the center of the bottom of the furnace 2 . A slag discharge channel 7 is provided at the bottom of the furnace 2 . The slag discharge channel 7 is close to the rotary shaft 3 . The upper end of the slag discharge channel 7 is provided with a side baffle 12 . The side baffle is located on the upper side of the slag discharge channel, which can prevent the ash on one side from being discharged directly from the slag discharge channel, so that the ash at the bottom of the furnace can accumulate a certain thickn...

Embodiment 2

[0031] The difference between embodiment 2 and embodiment 1 is: in embodiment 2, the direction of the cyclone formed by the secondary oxygen supply port 14 when blowing air is opposite to the direction of rotation of the rotary shaft 3, and the rest of the structure is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com