Self-excited vibration drag-reduction intertillage hiller

A self-excited vibration and soil-cultivating technology, used in agricultural machinery and implements, applications, plows, etc., can solve the problems of increased resistance to broken soil, increased soil viscosity, and easy agglomeration, so as to reduce farming resistance, reduce Low power consumption and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

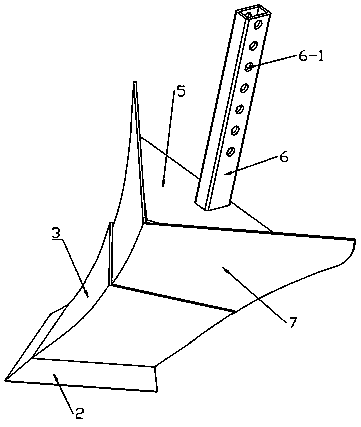

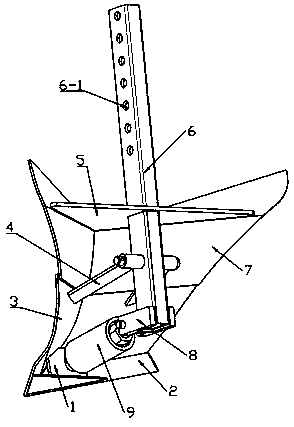

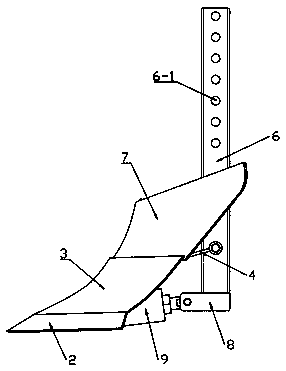

[0026] As shown in the figure, a self-excited vibration drag reduction cultivator includes a shovel tip 2, a shovel chest 3, a connecting plate 4, a fixed plate 5, a shovel handle 6, a soil-building plate 7, a positioning block 8, and a self-excited vibration device 9, The shovel handle 6 is provided with a fixed plate 5, the earth-building plate 7 is fixedly installed on the fixed plate 5, the shovel handle 6 below the fixed plate 5 is hinged with a connecting plate 4, and the shovel chest 3 is fixedly installed on the connecting plate 4, The shovel tip 2 is fixed on the lower end surface of the shovel chest 3, and the lower end of the shovel handle 6 is provided with a positioning block 8. The shovel tip 2, the shovel chest 3, and the earth-building board 7 all have a V-shaped structure, and the V-shaped tip of the shovel tip 2 is located at the front side of the V-shaped tip of the shovel chest 3 and the earth-building board 7.

[0027] The self-excited vibration device 9 i...

Embodiment 2

[0033] Such as figure 1 , 4 As shown in -6, a self-excited vibration drag reduction cultivator includes a shovel tip 2, a shovel chest 3, a connecting plate 4, a fixing plate 5, a shovel handle 6, a soil-building plate 7, a positioning block 8, and a self-excited vibration device 9, The shovel handle 6 is provided with a fixed plate 5, the earth-building plate 7 is fixedly installed on the fixed plate 5, the shovel handle 6 below the fixed plate 5 is hinged with a connecting plate 4, and the shovel chest 3 is fixedly installed on the connecting plate 4, The shovel tip 2 is fixed on the lower end surface of the shovel chest 3, and the lower end of the shovel handle 6 is provided with a positioning block 8. The shovel tip 2, the shovel chest 3, and the earth-building board 7 all have a V-shaped structure, and the V-shaped tip of the shovel tip 2 is located at the front side of the V-shaped tip of the shovel chest 3 and the earth-building board 7.

[0034] The self-excited vibr...

Embodiment 3

[0041] Such as Figure 1-2 , Shown in 4-6, a self-excited vibration drag reduction intertillage cultivator includes shovel tip 2, shovel chest 3, connecting plate 4, fixed plate 5, shovel handle 6, soil cultivating plate 7, positioning block 8, self-excited vibration device 9. The shovel handle 6 is provided with a fixed plate 5, and the earth-building plate 7 is fixedly installed on the fixed plate 5. The shovel handle 6 below the fixed plate 5 is hinged with a connecting plate 4, and the shovel chest 3 is fixedly installed on the connecting plate 4. Above, the shovel tip 2 is fixed on the lower end surface of the shovel chest 3, and the lower end of the shovel handle 6 is provided with a positioning block 8. The shovel tip 2, the shovel chest 3, and the earth-building board 7 all have a V-shaped structure, and the V-shaped tip of the shovel tip 2 is located at the front side of the V-shaped tip of the shovel chest 3 and the earth-building board 7.

[0042] The self-excited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com