Formula and processing method for pelleting seeds of Brassicarapa ssp. chinensis

The technology of a headed cabbage and a processing method, which is applied in the agricultural field, can solve problems such as pelletizing seeds of unsuitable non-headed cabbage, and achieve the effects of simple processing method, high clarity and promoting seed germination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

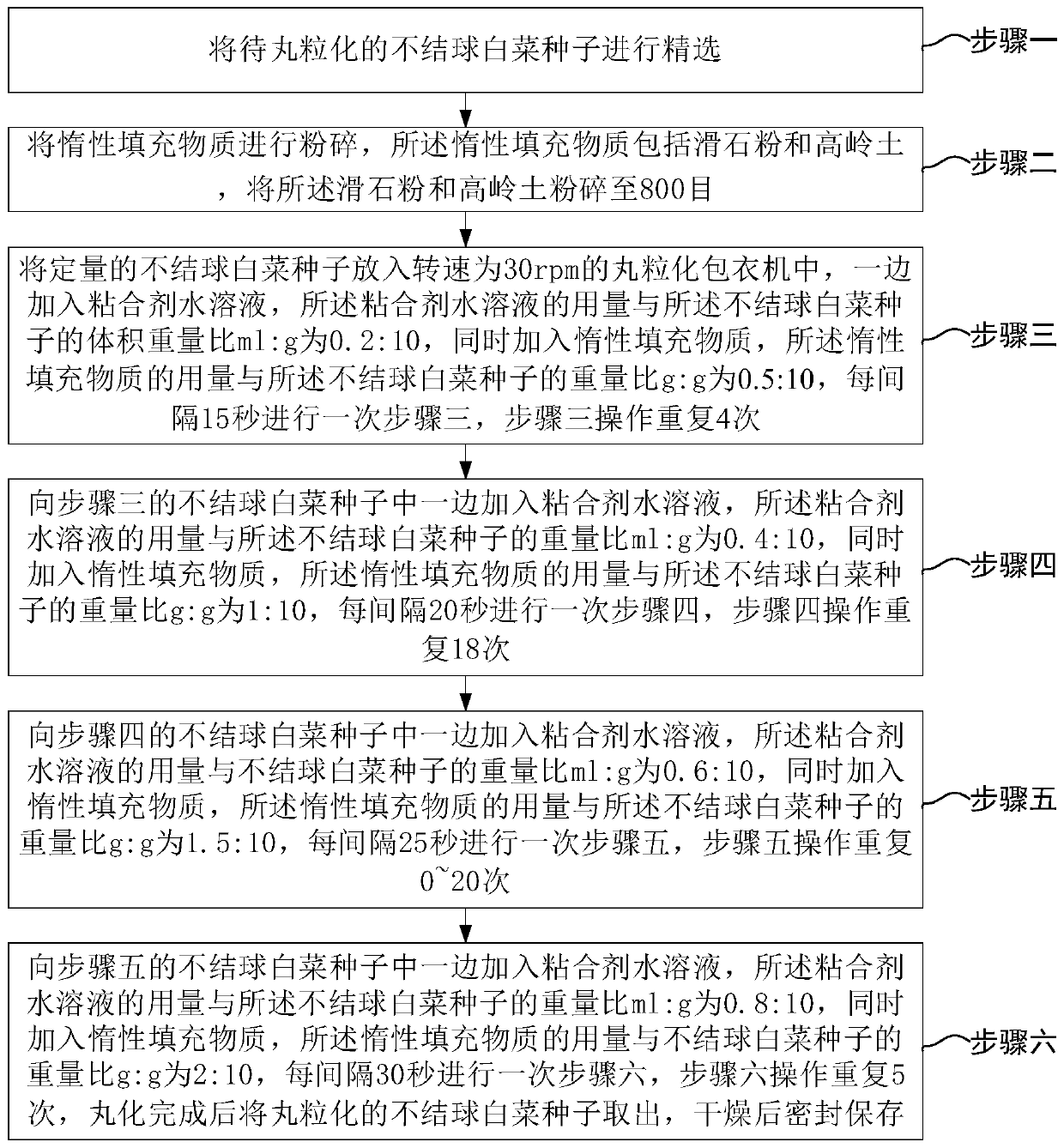

Method used

Image

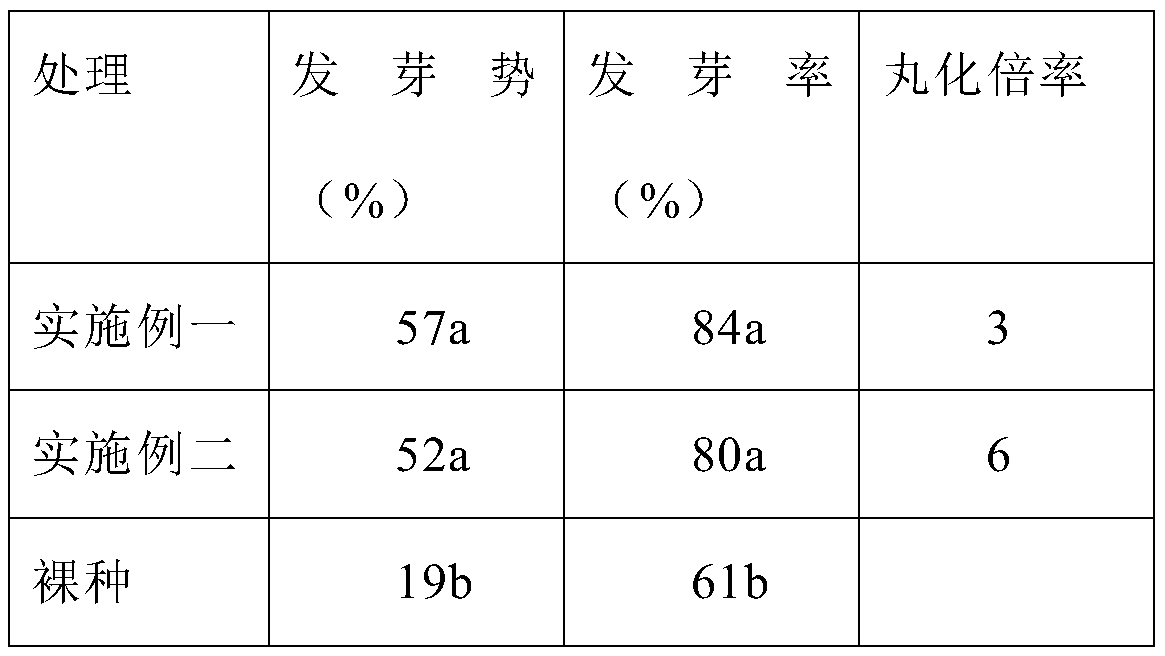

Examples

Embodiment 1

[0035] (1) Select the non-heading cabbage seeds to be pelletized.

[0036] (2) The talcum powder is crushed to 800 mesh, and the kaolin is crushed to 800 mesh.

[0037] (3) The aqueous binder solution is all polyvinyl alcohol solution, and the ratio of it to water is 4:100.

[0038] (4) Take 10g of seeds and put them into a pelletizing coating machine with a rotating speed of 30rpm, add the aqueous binder solution at a time, the dosage is 0.2ml, and add talc powder at the same time, the dosage is 0.5g, once every 15 seconds, The above operation was repeated 4 times.

[0039] (5) Add the binder aqueous solution to the seeds in step (4) at a time, the dosage is 0.4ml, and at the same time add the mixture of talcum powder and kaolin with a weight ratio of 1:1, the dosage is 1g, every 20 seconds, repeat the above operation 18 times.

[0040] (6) Add the binder aqueous solution to the seeds in step (5), the dosage is 0.8ml, and at the same time add talcum powder, the dosage is 2...

Embodiment 2

[0042] (1) Select the non-heading cabbage seeds to be pelletized.

[0043] (2) The talcum powder is crushed to 800 mesh, and the kaolin is crushed to 800 mesh.

[0044] (3) configure the adhesive aqueous solution to be polyvinyl alcohol solution, and its proportioning ratio with water is 4:100;

[0045] (4) Take 10g of seeds and put them into a pellet coating machine with a rotating speed of 30rpm, add the aqueous binder solution at a time, the dosage is 0.2ml, and add talcum powder at the same time, the dosage is 0.5g, once every 15 seconds, The above operation was repeated 4 times.

[0046] (5) Add the binder aqueous solution to the seeds in step (4) at a time, the dosage is 0.4ml, and at the same time add the mixture of talc powder and kaolin with a weight ratio of 1:1, the dosage is 1g, and the above operation is repeated every 20 seconds 18 times.

[0047] (6) Add the binder aqueous solution to the seeds in step (5) once, the dosage is 0.6ml, and at the same time add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com