Rotary non-dead-angle lighting soilless culture vegetable planting machine

A technology of soilless cultivation and no dead angle, applied in the direction of soilless cultivation, cultivation, botany equipment and methods, etc., can solve the problems of complex structure and high production cost, and achieve the effect of simple installation and operation, complete functions, and improvement of indoor air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

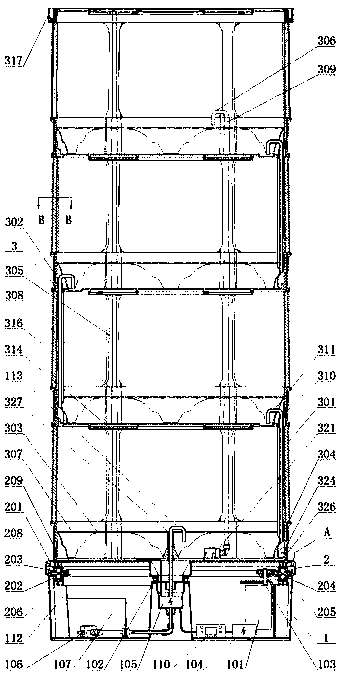

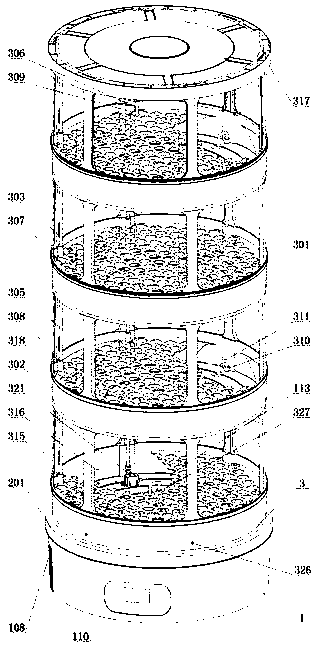

[0035] Such as figure 1 and figure 2 Shown: a rotary type non-dead angle daylighting and soilless cultivation vegetable planting machine provided by the present invention, including a base 1, an electric control turntable 2 and a cultivation frame 3, an electric control turntable 2 is installed on the base 1, and a cultivation is installed on the electric control turntable 2 frame 3.

[0036] The electric control turntable 2 installed on the top of the base 1 is used to provide the cultivation frame 3 with a rotation function, so that it can rotate 360 degrees without dead angles to collect sunlight.

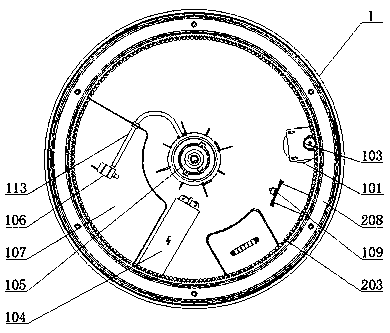

[0037] see image 3 and Figure 4 : The base 1 is a box structure, the base 1 is provided with a water tank 107, the water tank 107 is equipped with a supplementary water pump 106, and the supplementary water pump 106 supplies water to the planting tray at the bottom; a motor 101, a power supply 104, and a conductive slip ring 105 are also installed in the base 1 , Motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com