Multi-element substrate, graphene capable of continuously adjusting layer number based on multi-element substrate and preparation method

A graphene and substrate technology, applied in the field of graphene material preparation, can solve problems such as undeveloped graphene films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

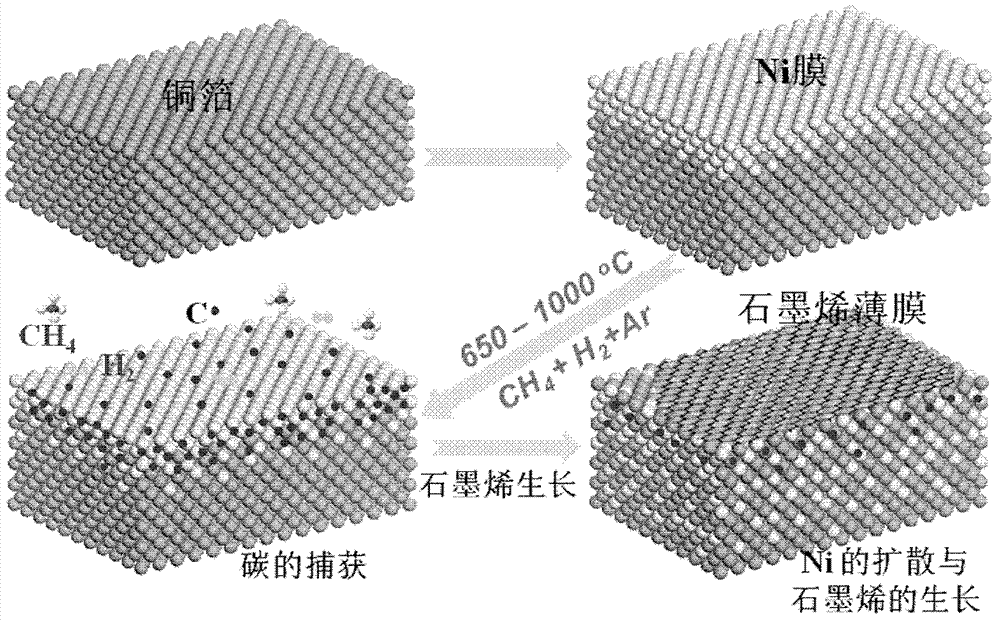

[0042] Preparation of novel multi-component substrates

[0043] The method for preparing the multi-component substrate is the following method a or method b:

[0044] Method a: In low-carbon-soluble metal M1, or alloy M1 of low-soluble carbon metal M1 and high-soluble carbon metal M2 1-x +M2 x (x1-x +M2 x (x>0.5) film to obtain the multi-component substrate;

[0045] Method b: preparing a layer of low-carbon-soluble metal M1, or an alloy M1 of low-carbon-soluble metal M1 and high-carbon-soluble metal M2 on a non-metallic substrate 1-x +M2 x (x1-x +M2 x (x>0.5) film to obtain the multi-component substrate.

[0046] In the above method a and method b, the metal M1 is Cu, and the metal M2 includes Ru, Ti, Zr, Nb, Ta, Fe, Co, Ni, V, Rh, Pd, Co, lr, Pt, Mo , W, Zn and other metals at least one.

[0047] In said method a, said metal M1 or alloy M1 1-x +M2 x (x1-x +M2 x (x>0.5) The number of layers of the film is one or more layers, preferably one layer, and the thickness ...

Embodiment 1

[0078]Ni films were deposited on 25 μm Cu foil substrates by magnetron sputtering. Using high-purity Ni (99.99%) as the target material, the background vacuum pumped to 3.0×10 -4 Pa, using argon with a purity of 99.99% as the working gas, the working pressure is maintained at 0.8Pa; using room temperature sputtering, the distance between the target and the substrate is set to 7cm; using radio frequency magnetron sputtering, the sputtering power is 70W, the deposition time For 40 minutes, the total thickness of the prepared film was 0.6 μm.

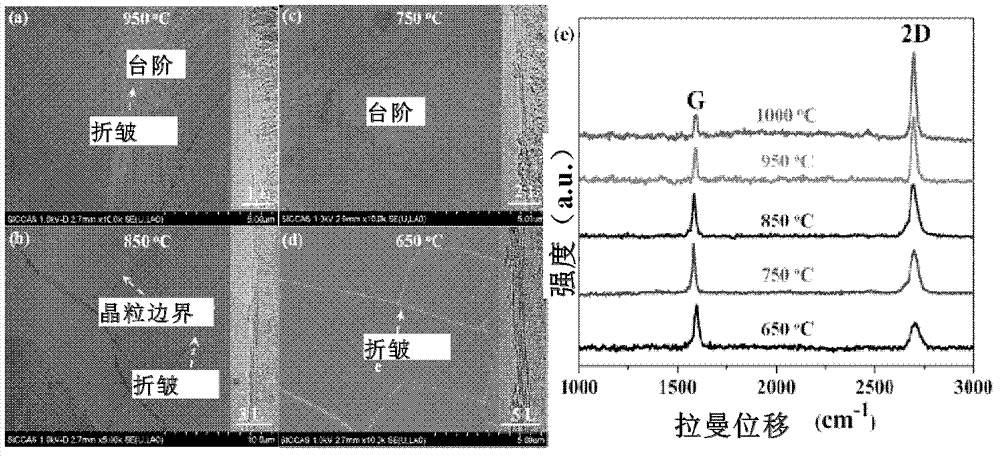

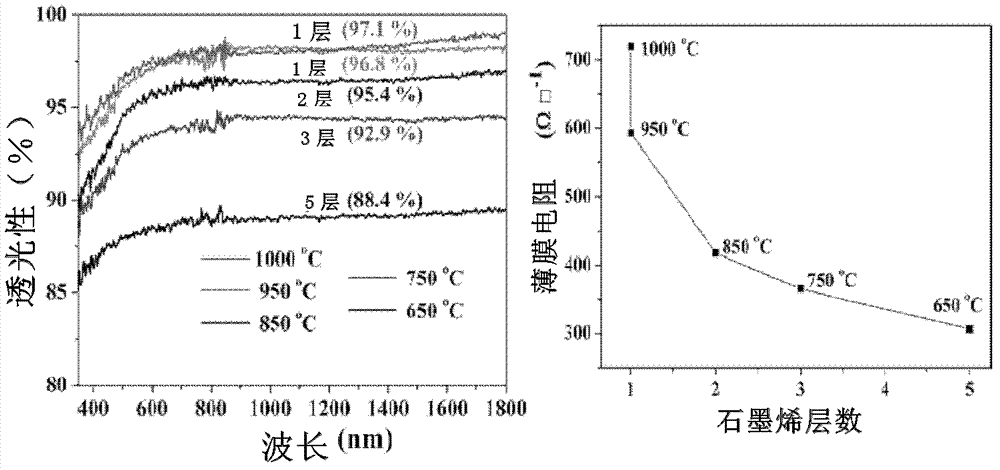

[0079] Put the Cu foil / Ni thin film binary substrate prepared above into the chemical vapor deposition reaction chamber, seal it, check the air tightness, and put it in the protective atmosphere Ar+H 2 Exhaust down, then heat until the reaction temperature is 650°C, 750°C, 850°C, 950°C, 1000°C respectively, after 10 minutes of constant temperature, introduce carbon source CH 4 , hydrogen and protective gas, the gas flow rate is 2 sccm, a...

Embodiment 2

[0088] Ni films were deposited on 25 μm Cu foil substrates by magnetron sputtering. With high-purity Co (99.99%) as the target material, the background vacuum pumped to 3.0×10 -4 Pa, with argon with a purity of 99.99% as the working gas, the working pressure is maintained at 0.8Pa, room temperature sputtering is used, the distance between the target and the substrate is set to 7cm, radio frequency magnetron sputtering is used, the sputtering power is 80W, and the deposition The time is 20 minutes, and the total thickness of the prepared polycrystalline Ni film is 0.2 μm.

[0089] Put the Cu foil / Ni film binary substrate prepared above into the chemical vapor deposition reaction chamber, seal it, check the air tightness, and heat it at room temperature for 25 minutes in hydrogen (flow rate is 400sccm) and argon (flow rate is 500sccm) After reaching 900°C, keep the temperature for 20 minutes for annealing, and then raise the temperature to 1000°C for 5 minutes, and then pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com