Polymer coating mixing equipment

A polymer and coating technology, used in mixers, shaker/oscillation/vibration mixers, mixers with rotary stirring devices, etc., which can solve the damage of transmission parts, the small amount of single mixing, and affect the coating effect, etc. problem, to achieve the effect of increasing the storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

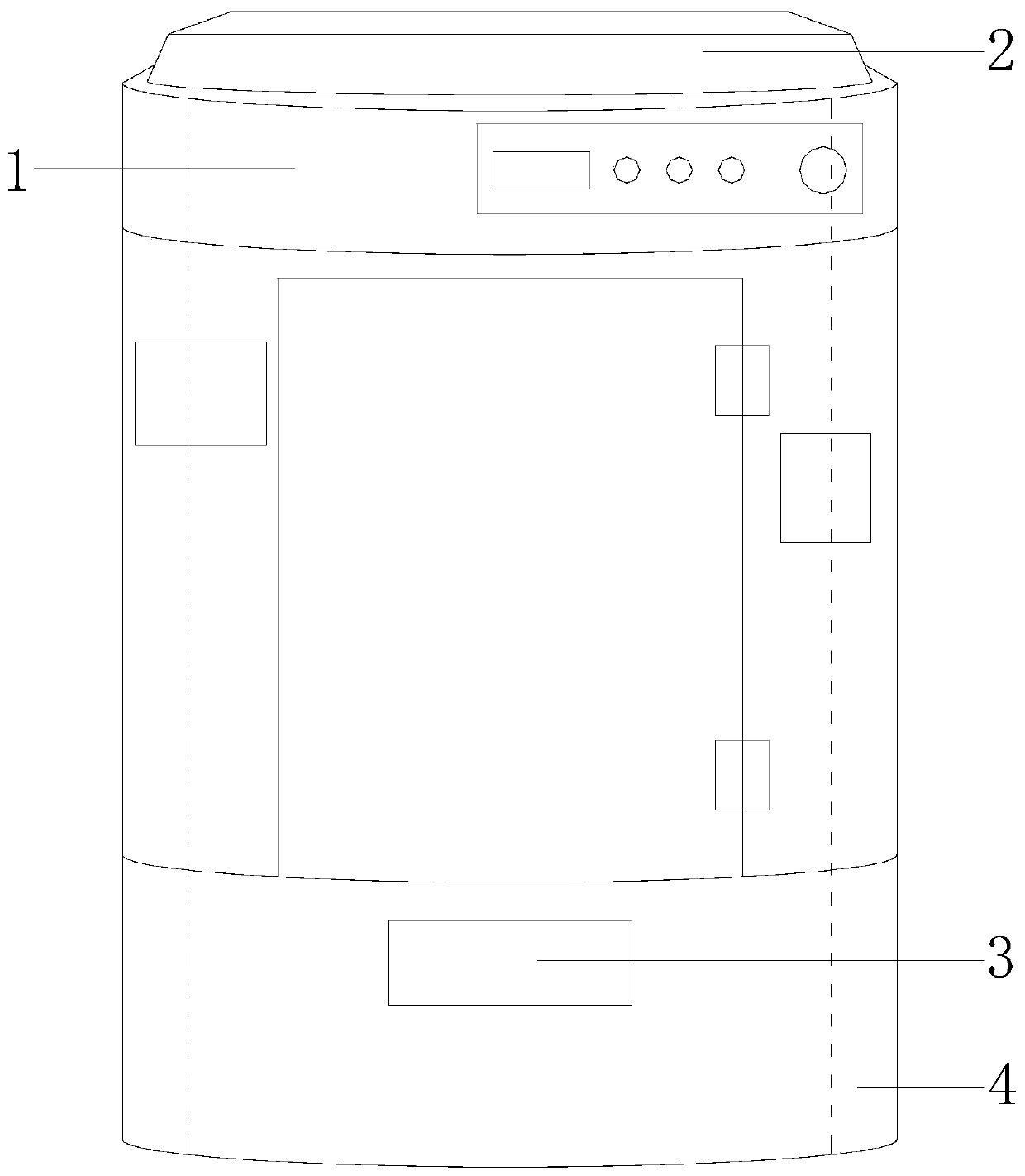

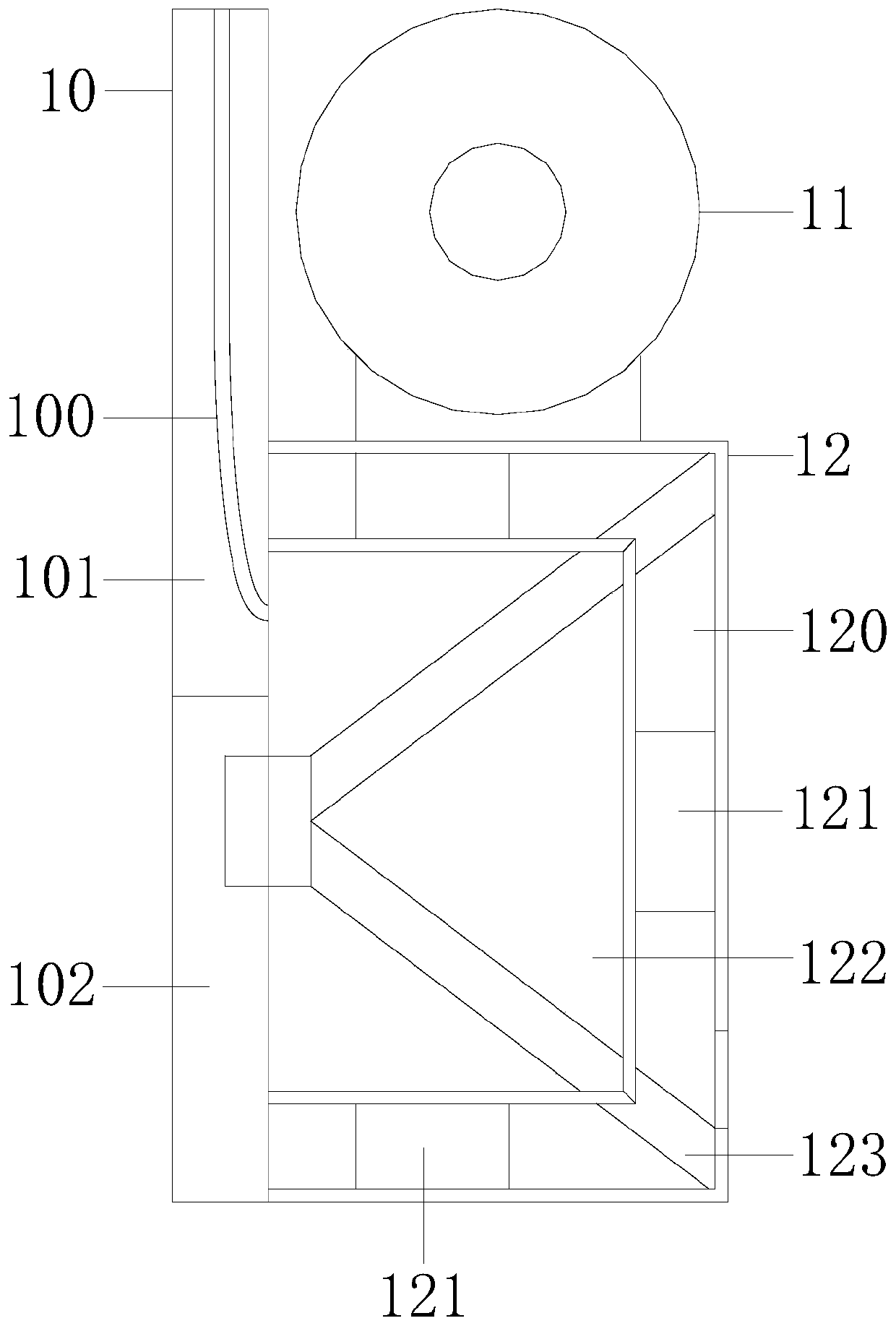

[0027] Example 1 please refer to Figure 1-2 , The present invention provides a technical solution for polymer coating mixing equipment: its structure includes a mixing device 1, a feeding top frame 2, a material outlet 3, and a machine frame 4, and the mixing device 1 is installed inside the machine frame 4. , the feeding top frame 2 is locked with the upper end of the machine frame 4, the discharge port 3 is installed at the front end of the machine frame 4, and the mixing device 1 is composed of a feeding structure 10, a motor 11, and a mixing cylinder 12. The feeding structure 10 is installed and connected to the left end of the mixing cylinder 12, the bottom of the motor 11 is locked on the mixing cylinder 12, and the feeding structure 10 includes an arc hopper 100, a feeding upper frame 101, and a feeding bottom frame 102 , the arc bucket 100 is mounted on the feeding upper frame 101 and the two form an integrated structure, the bottom of the feeding upper frame 101 is a...

Embodiment 2

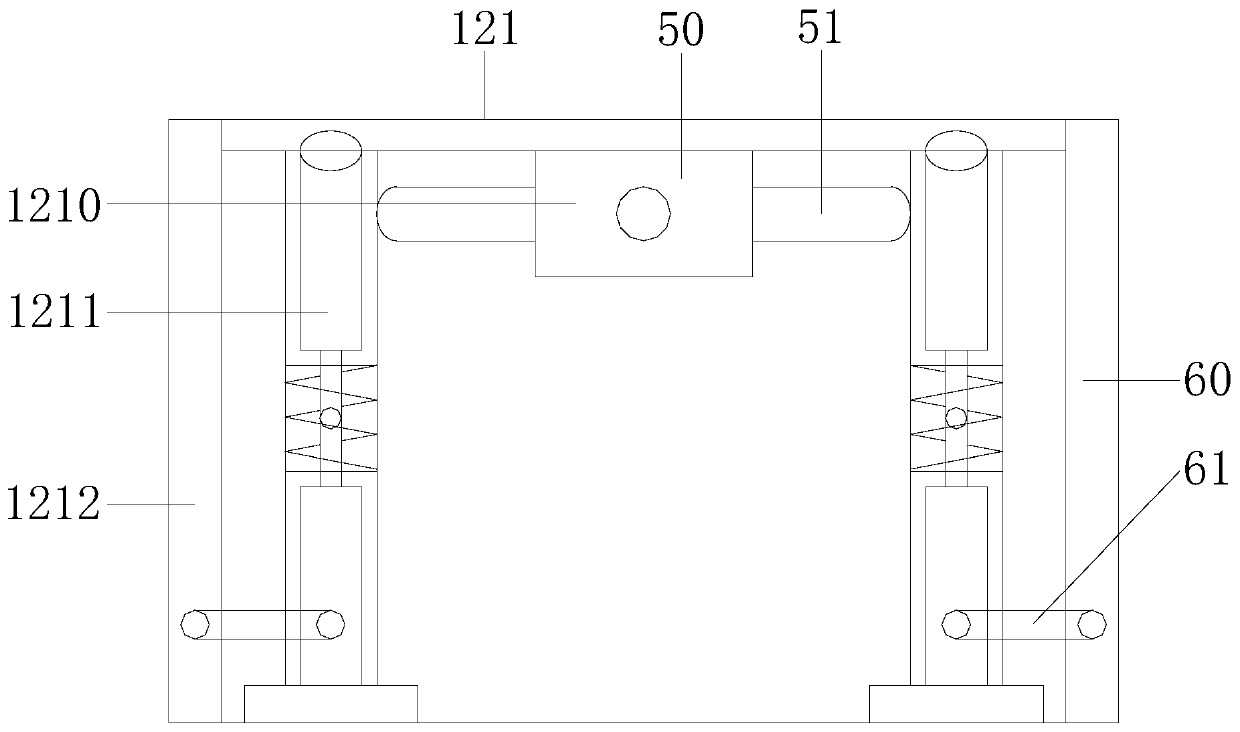

[0029] Example 2 please refer to Figure 3-7, the present invention provides a technical solution for a polymer coating mixing equipment: the vibrator 121 includes a vibration motor 1210, a vibration rod 1211, and a vibration frame 1212. The vibration motor 1210 is locked inside the vibration frame 1212, so The left and right sides of the vibration motor 1210 are attached to the vibration rod 1211. The vibration rod 1211 is composed of three parts, and the middle part plays a main swing role. The upper and lower ends of the vibration rod 1211 are installed and connected to the vibration machine frame 1212. The vibration motor 1210 includes a motor body 50 and a push rod 51 . The ring side of the motor body 50 is installed and connected to the push rod 51 . The vibration frame 1212 includes a frame body 60 and a limit bar 61 . The frame body 60 It is connected with the right end shaft of the limiting rod 61. The limiting rod 61 acts as a limit to the swing of the vibration rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com