Casting powder for PSB830 steel cast blank and preparation method of casting powder

A technology for mold slag and steel casting, which is applied in the field of steelmaking and can solve problems such as surface depressions of casting billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

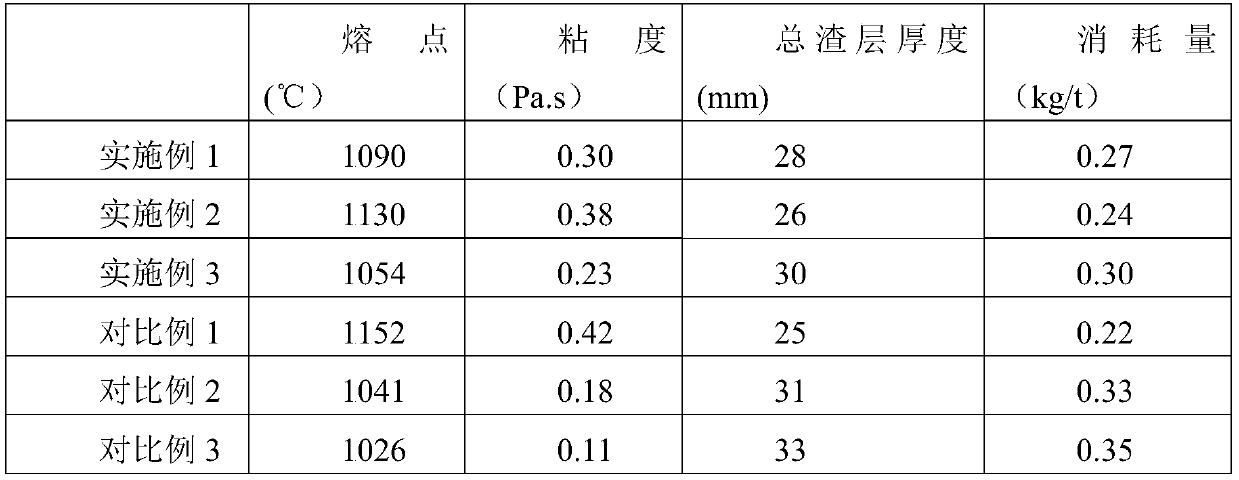

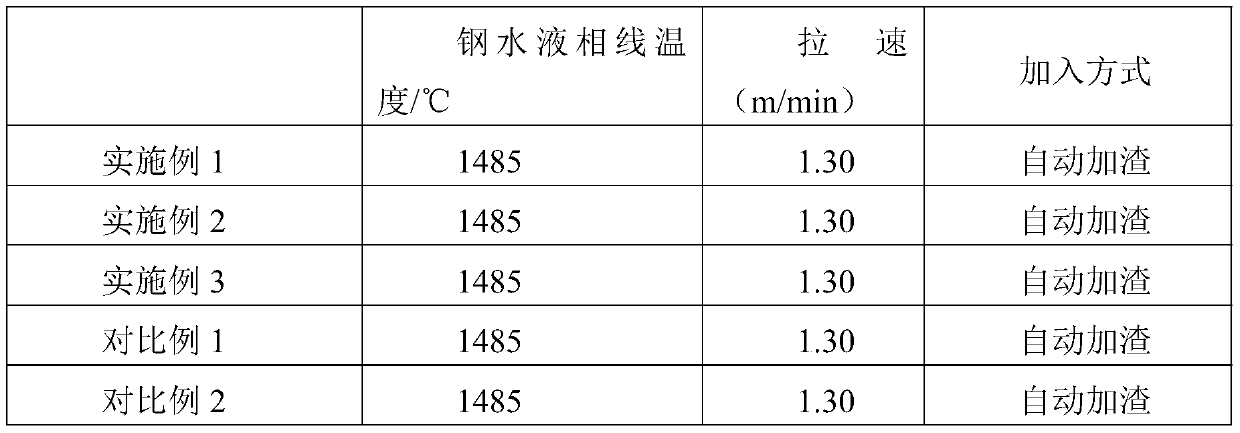

Embodiment 1

[0027] Mix the basic slag, co-solvent and melting rate regulator, melt and cool, dry and grind to obtain mold slag, wherein the mass percentage of each component in the mold slag is: CaO 32.0%, SiO 2 33.0%, Al 2 o 3 4.0%, MgO 5.0%, Na 2 O 6.5%, F 5.0%, Fe 2 o 3 3.0%, C 10.5%, the control alkalinity is 0.95.

Embodiment 2

[0029] Mix the basic slag, co-solvent and melting rate regulator, melt and cool, dry and grind to obtain mold slag, wherein the mass percentage of each component in the mold slag is: CaO 29.2%, SiO 2 33.6%, Al 2 o 33.2%, MgO 4.6%, Na 2 O 7.8%, F 6.2%, Fe 2 o 3 2.2%, C 10.3%, the control alkalinity is 0.87.

Embodiment 3

[0031] Mix the basic slag, co-solvent and melting rate regulator, melt and cool, dry and grind to obtain mold slag, wherein the mass percentage of each component in the mold slag is: CaO 34.4%, SiO 2 33.4%, Al 2 o 3 5.3%, MgO 4.2%, Na 2 O 7.1%, F 4.1%, Fe 2 o 3 2.6%, C 8.1%, the control alkalinity is 1.03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com