3D printing gold spraying equipment, 3D printing device and control method thereof

A technology of 3D printing and gold-spraying equipment, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of low utilization rate of zinc wire and large dust, and achieve high material utilization rate, low oxidation and gasification rate, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

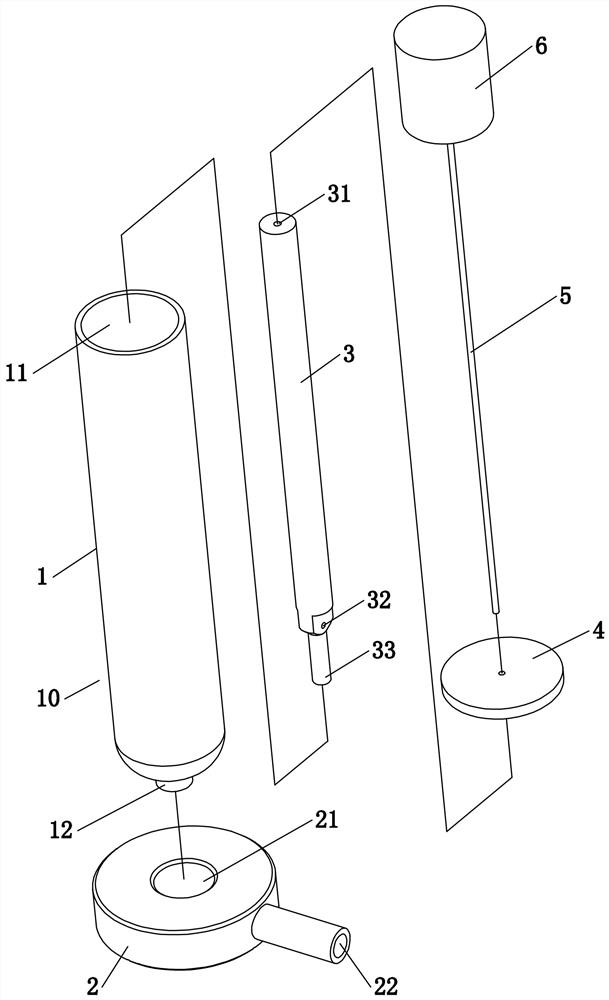

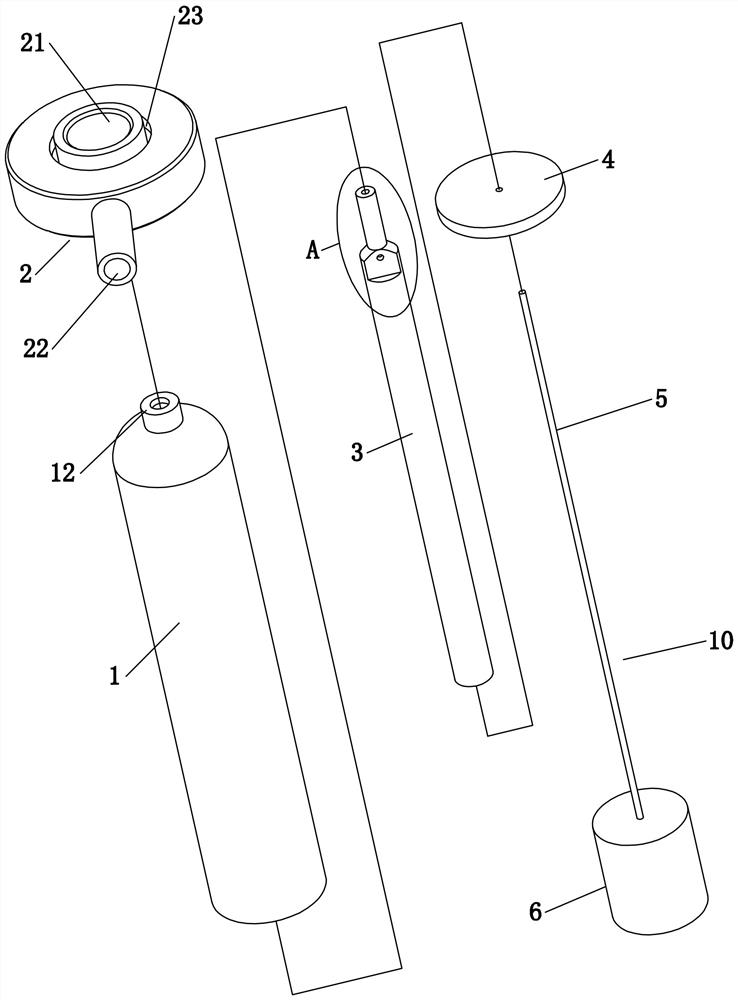

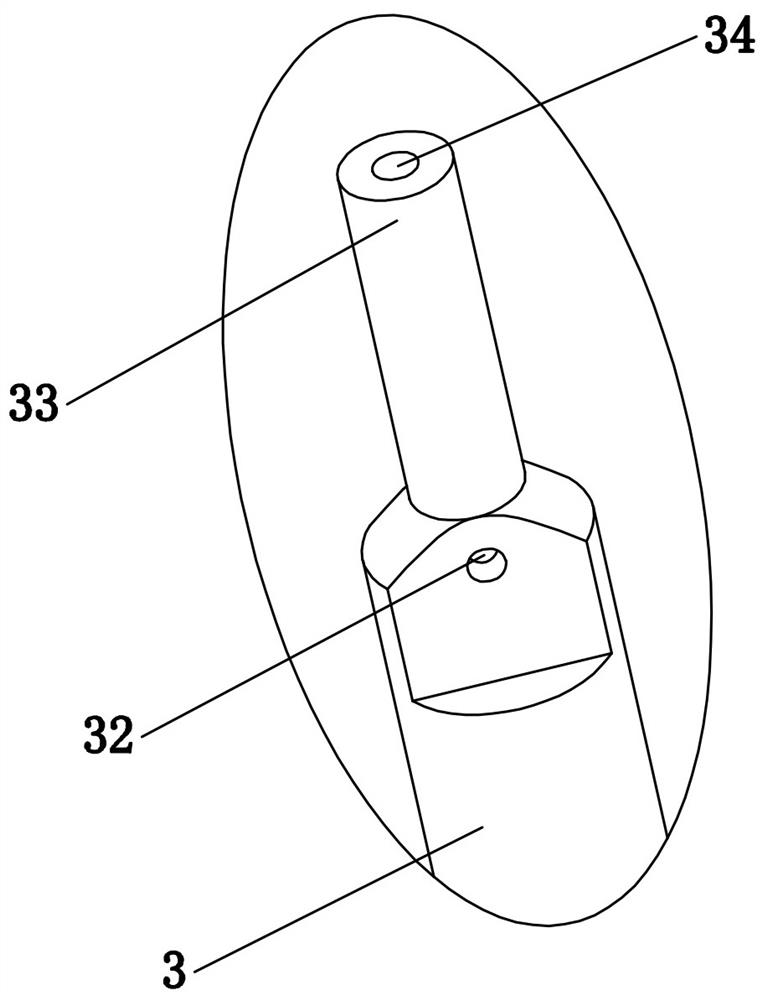

[0037] see Figure 1 to Figure 9 As shown, a 3D printing gold spraying device includes a metal droplet 3D printing device 10, the metal droplet 3D printing device 10 is provided with a metal droplet output port 34, and also includes a metal droplet outlet 34 for the metal droplet output port 34. The supersonic air curtain disperser 2 blown out by the molten droplets, the supersonic air curtain disperser 2 is arranged outside the output port 34 of the metal molten droplets.

[0038] The supersonic air curtain disperser 2 includes a housing, the housing is provided with a negative pressure channel 21, a jet port 23 and an air inlet 22, the jet port 23 is arranged on the lower periphery of the negative pressure channel 21, and the jet port 23 passes through the air inlet The port 22 is connected to the gas source, and the upper end of the negative pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com