Full-automatic one-step forming system for assembly-type building steel beam

A fully automatic, prefabricated technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to reduce operating losses and achieve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

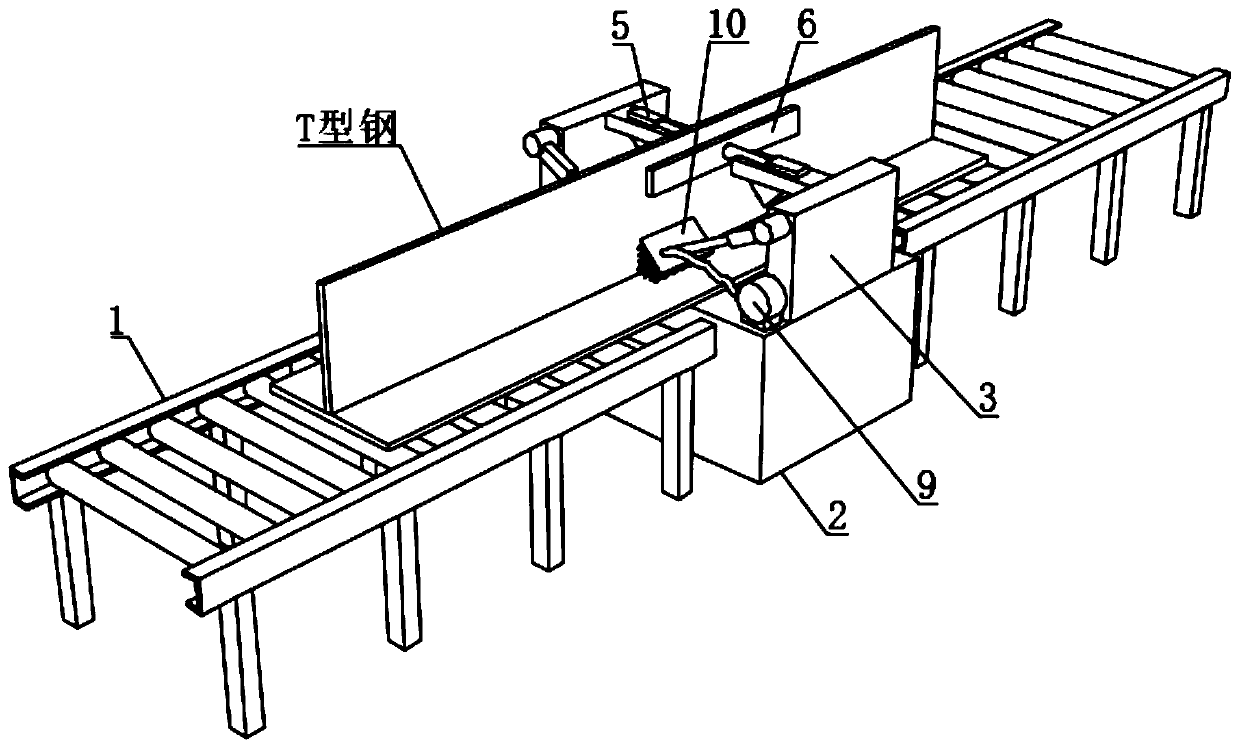

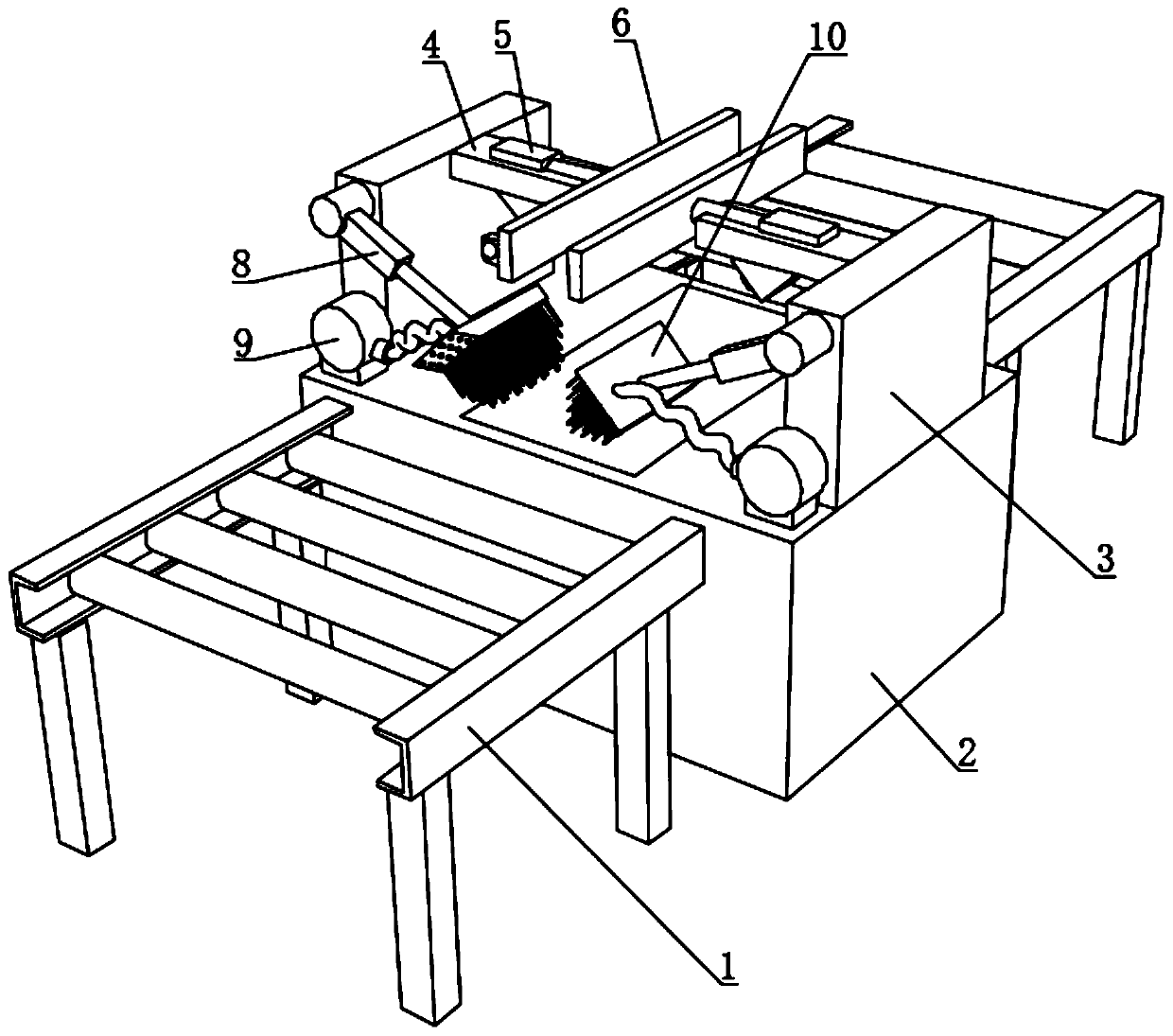

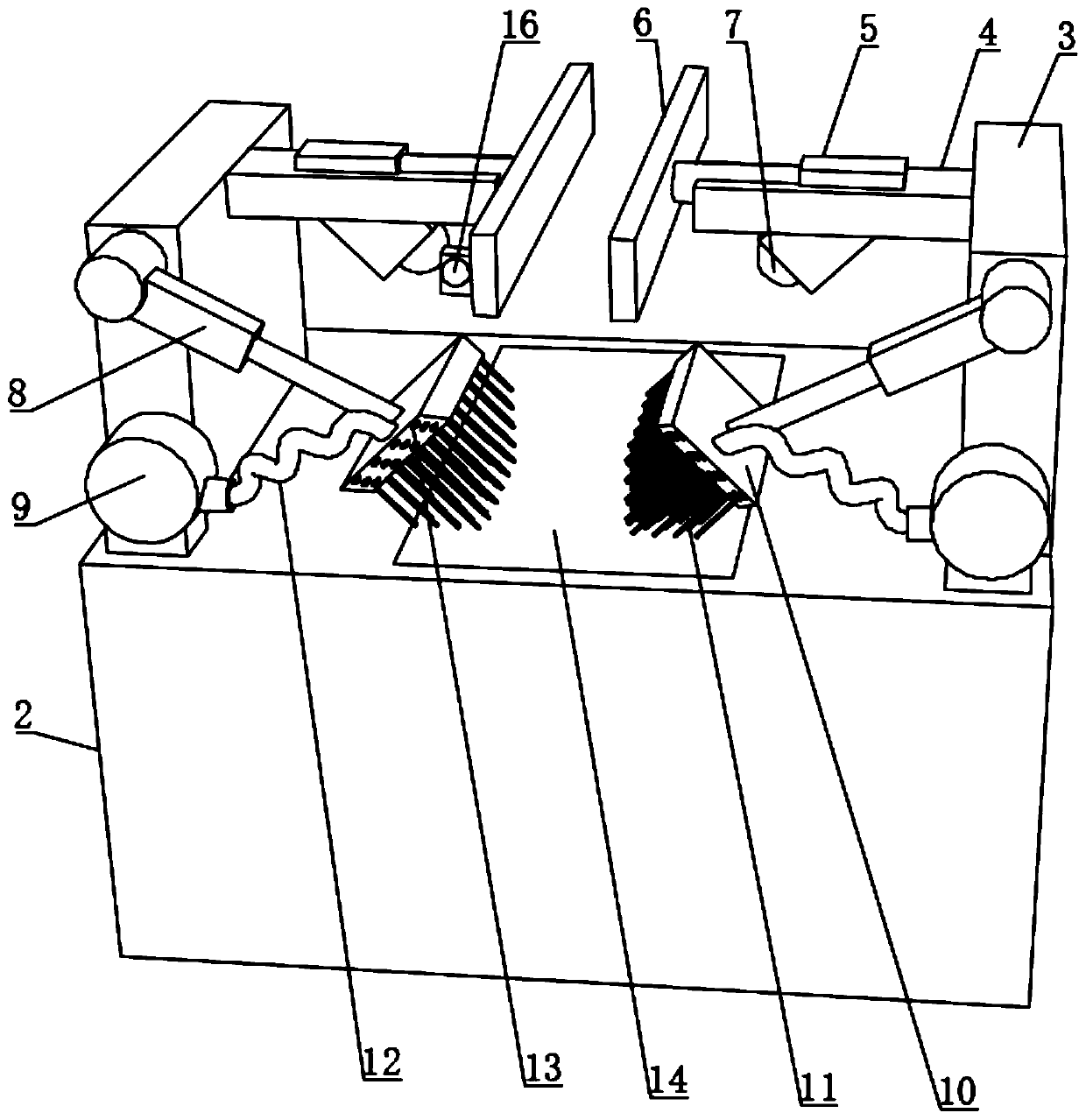

[0043] see figure 1 , a kind of prefabricated building steel girder fully automatic one-time forming system, including a conveying mechanism 1, the conveying mechanism 1 is sequentially connected with a pre-assembly mechanism (not shown in the figure), a first alignment welding mechanism (not shown in the figure), Turn over the docking assembly mechanism (not shown in the figure) and the second alignment welding mechanism (not shown in the figure), the pre-assembly mechanism is used for assembling the web and the first wing plate, and the first alignment welding mechanism is used When the web and the first wing are aligned and welded together to form a T-shaped steel, the overturning butt joint assembly mechanism is used to turn the T-shaped steel over and assemble it with the second wing, and the second alignment welding mechanism is used to The T-shaped steel is aligned with the end of the second wing plate and assembled and welded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com