A vertical five-axis linkage machine tool

A five-axis linkage machine tool, vertical technology, used in metal processing machinery parts, manufacturing tools, metal processing and other directions, can solve problems such as dangerous accidents, secondary loss of linear motor control, etc., to prevent dangerous accidents, good buffering and anti-collision effect. , Good buffering and anti-collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

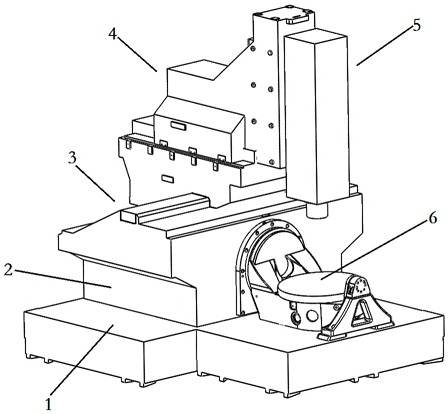

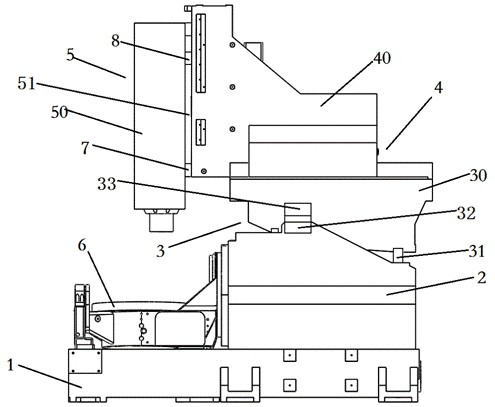

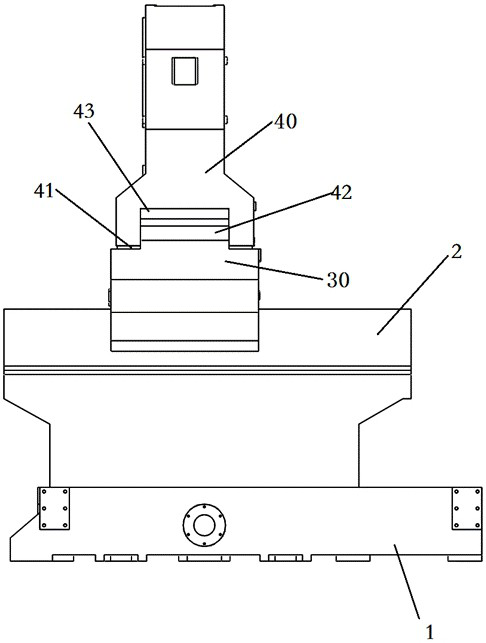

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a vertical five-axis linkage machine tool includes a machine bed 1, a base 2, an X-axis moving assembly 3, a Y-axis moving assembly 4, a Z-axis moving assembly 5, and a cradle-type workbench 6. The base 2 is fixed Installed on the machine bed 1, the X-axis moving assembly 3 includes an X-axis sliding table 30 arranged above the base 2, and an X-axis sliding table 30 arranged between the X-axis sliding table 30 and the base 2 for driving the X-axis sliding table 30. An X-axis driving device that freely reciprocates along the X-axis direction and an X-axis slide rail 31 provided on the base 2, the X-axis slide table 30 is slidably connected to the X-axis slide rail 31, and the Y-axis moving assembly 4 includes The Y-axis slide table 40 arranged above the X-axis slide table 30, and the Y-axis drive for driving the Y-axis slide table 40 to freely reciprocate along the Y-axis direction between the ...

Embodiment 2

[0034] This embodiment should be understood as including all the technical features of the foregoing embodiments, and will be further specifically described on the basis of the foregoing embodiments.

[0035] Such as Figure 7 As shown, a self-locking slider 8 is provided on the Z-axis slide table 50, and the self-locking slider 8 includes a slider seat 80 fixedly connected with the Z-axis slide table 50. Among the slider seats 80 A U-shaped groove 88 is provided, and the groove 88 is sequentially provided with a second spring 81, a horizontal plate 82, a support rod 83, an L-shaped air injection pipe 89 and a contact with the Z-axis slide rail 51 from the inside to the outside. Rubber block 84, one end of the second spring 81 is fixedly connected to the bottom of the groove 88, the other end of the second spring 81 is fixedly connected to the horizontal plate 82, and one end of the pole 83 is fixedly connected to the horizontal plate 82 , the other end of the pole 83 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com