Turning tool wear determination method based on adversarial neural network

A neural network and judgment method technology, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve problems such as insufficient number of samples, unsatisfactory diagnostic results, and difficulty in developing deep learning models, so as to avoid rejection rates. The effect of increasing and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments.

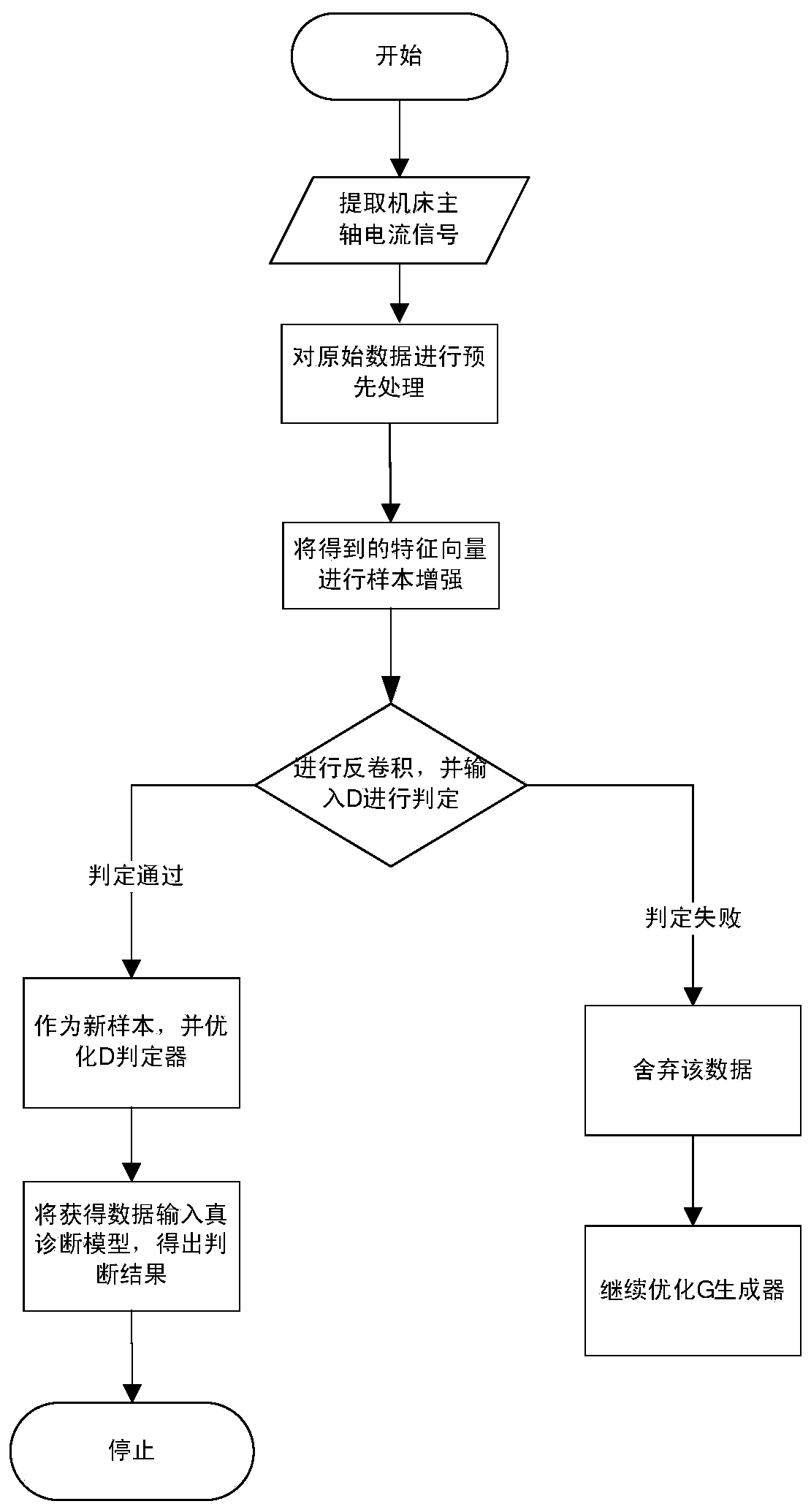

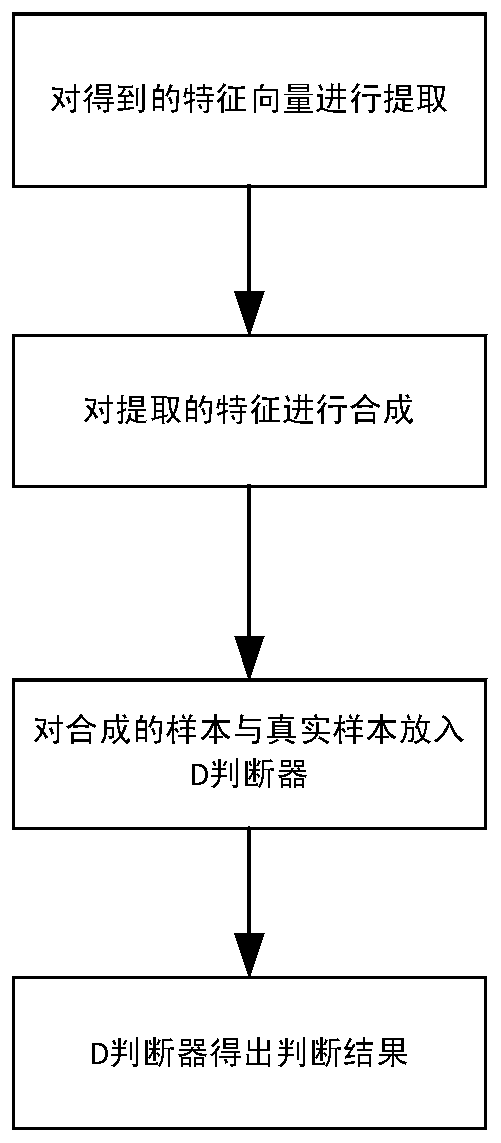

[0029] Such as Figure 1-Figure 3 As shown, a method for determining the wear of a turning tool based on an anti-neural network includes the following steps:

[0030] S1: Collect spindle current signal data in CNC machine tools. The collected spindle current signal data in the CNC machine tool includes the current signal of the spindle idling and the current signal of the spindle load from the beginning to the wear of the tool.

[0031] S2: Perform data preprocessing on the collected spindle current signal data in the CNC machine tool, use wavelet packet transform analysis to obtain a time-frequency graph, and convert the time-frequency graph into a 64*64*3 image. Using moving average signal extraction, using wavelet packet transform analysis, and transforming the obtained image.

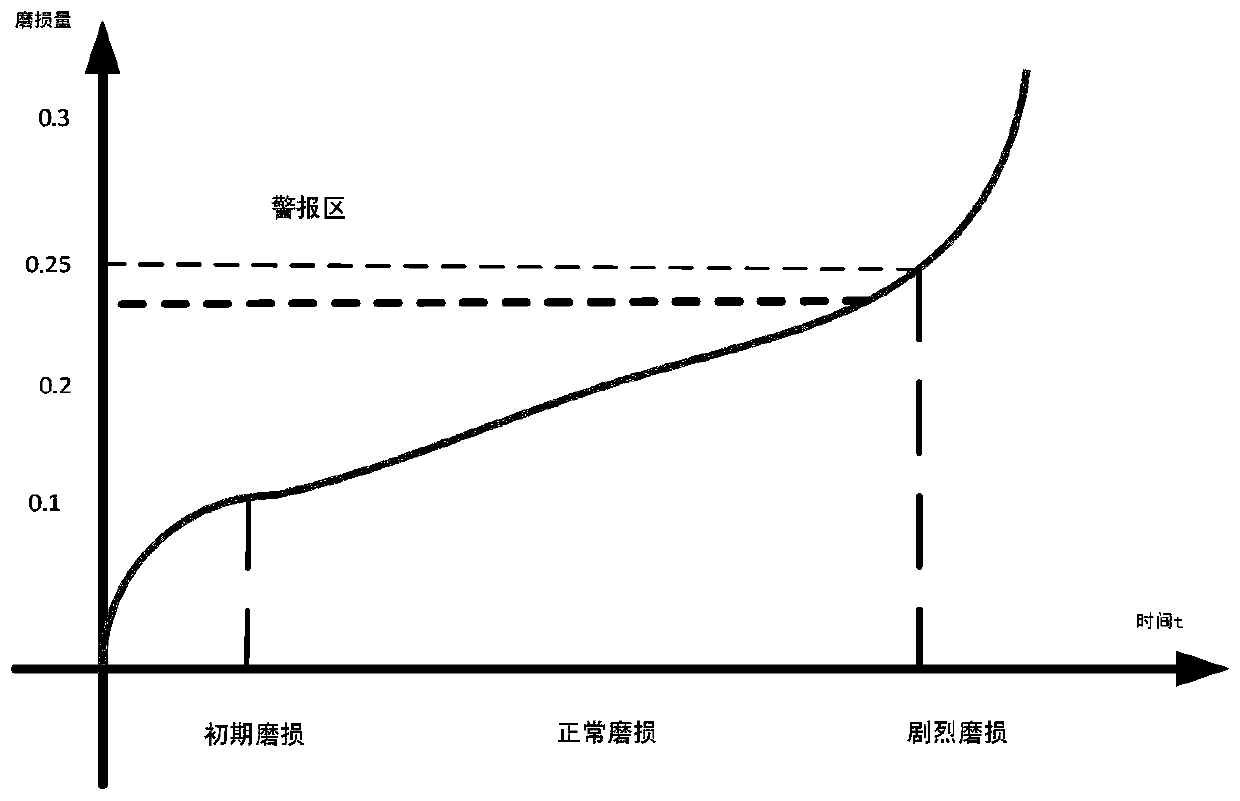

[0032] S3: Using prior knowledge, when the wear of the turning tool is 0.252mm, the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com