High-precision grinding drill bit

A high-precision, drill-bit technology, used in grinding machine parts, grinding/polishing equipment, tools for shearing machines, etc., can solve the problems of poor waterproof performance, low precision, and low product quality, and achieve Strong waterproof, good quality, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

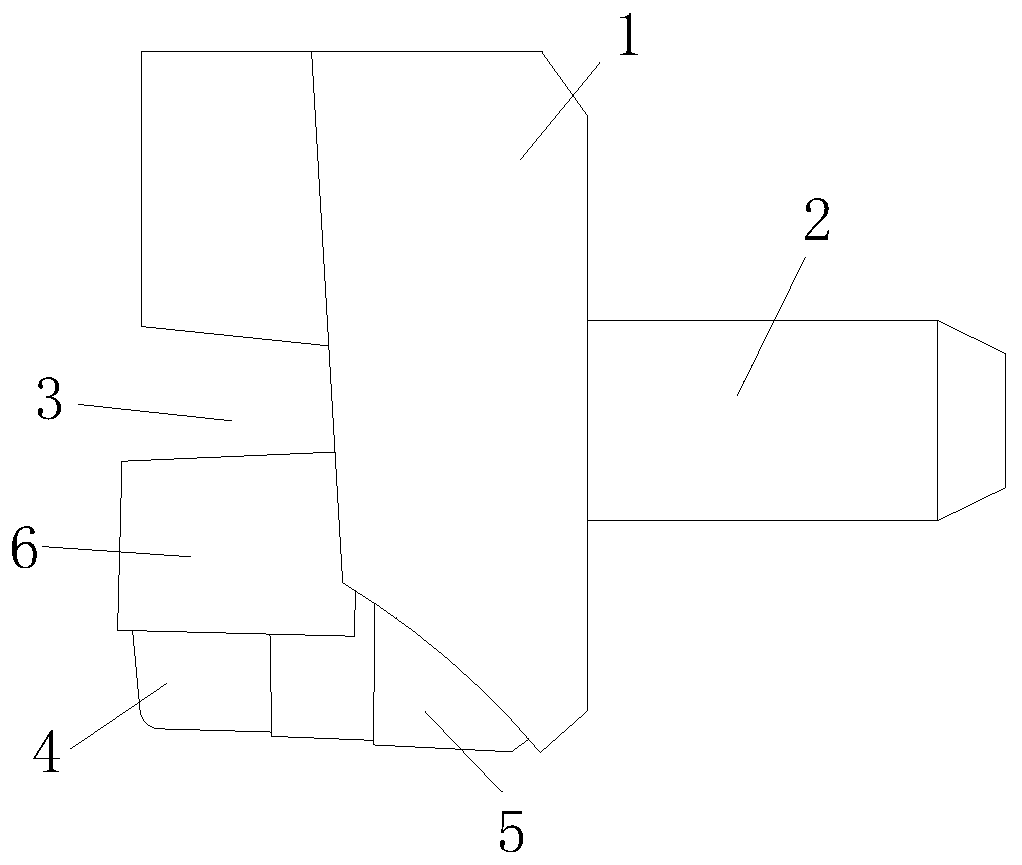

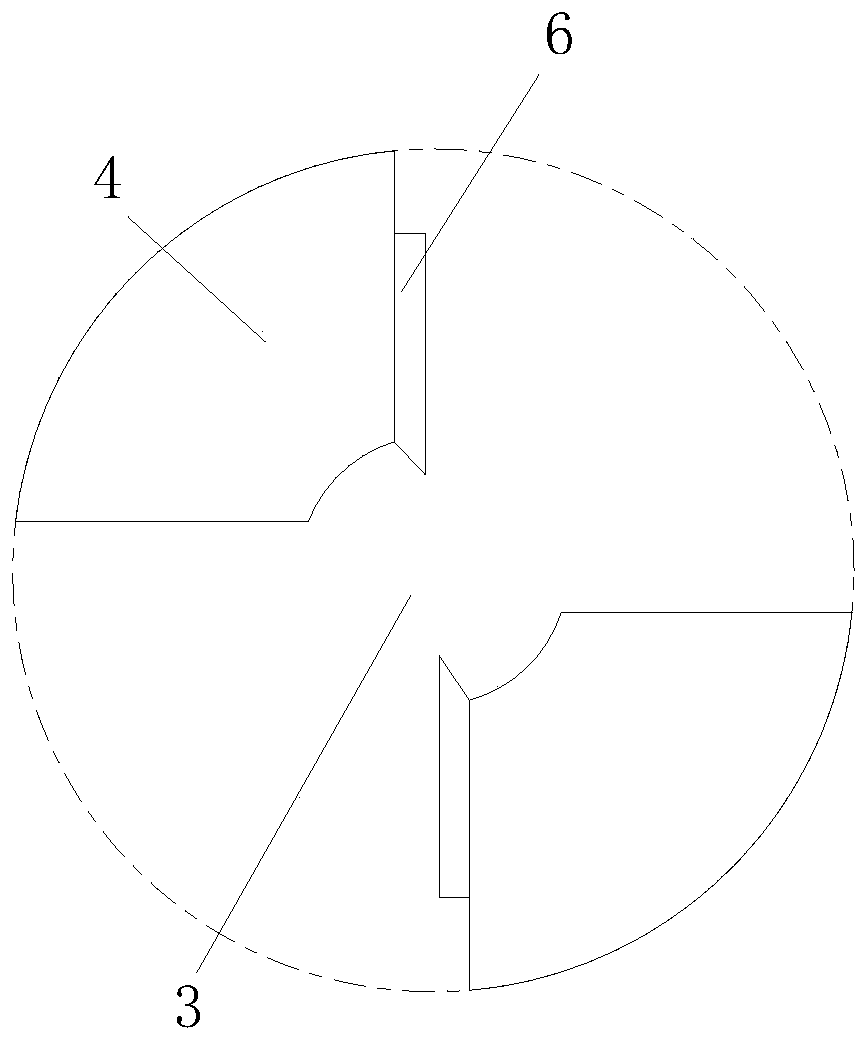

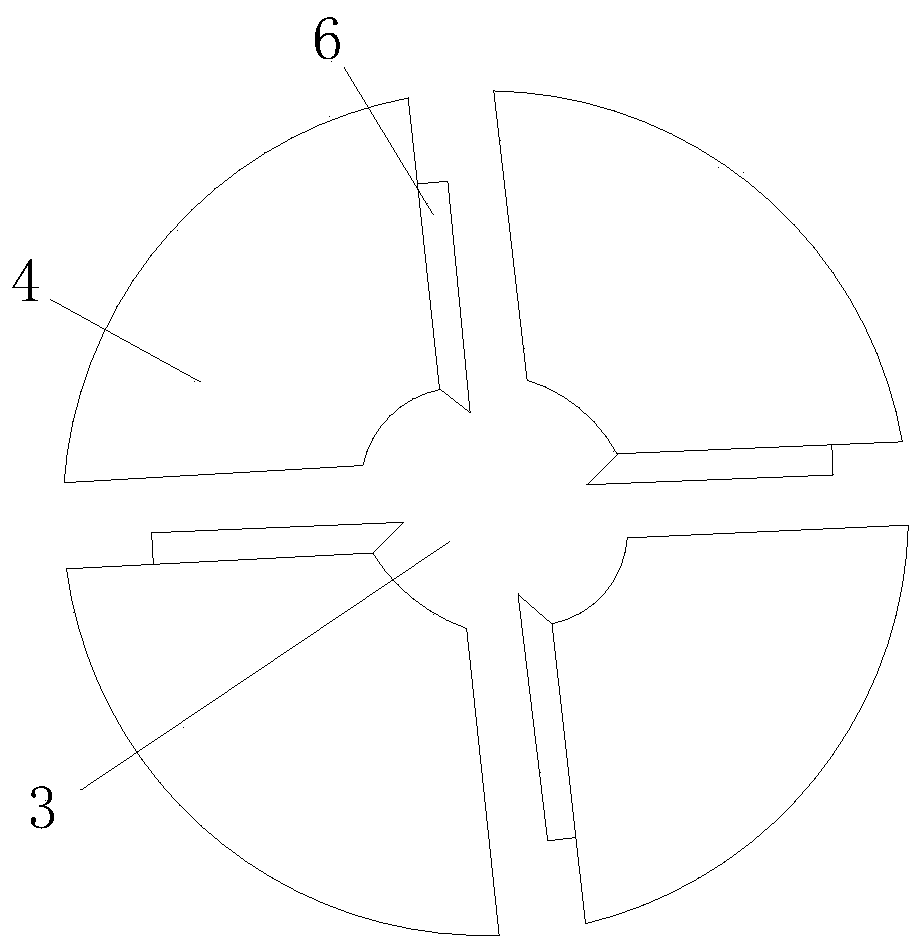

[0026] Attached below Figure 1-4 The present invention is further described with embodiment:

[0027] A high-precision grinding drill bit, including a fixed plate 1 and a side shear plate 4, two side shear plates 4 are provided, and the two side shear plates 4 are connected to the fixed plate 1, and the two side shear plates 4 are connected to the fixed plate 1. The side shearing plate 4 is misplaced, and the end of the fixed plate 1 away from the side shearing plate 4 is connected with a connecting column 2, and the side shearing plate 4 is connected with a side shearing knife 6, and the two side shearing plates 4 A central cavity 3 is arranged between them, and an oblique shear groove 5 is provided on the side wall of the fixed plate 1. By adding a grinding drill bit, in actual use, the grinding of a specific pipeline can be realized by setting the grinding drill bit. In order to ensure the accuracy and quality of grinding, and at the same time, the quality of the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com