Protective fabric, preparation method and application thereof

A fabric, waterproof and moisture-permeable technology, applied in the field of textile fabrics, can solve the problems of high cost of use, poor comprehensive protection, poor environmental protection, etc., and achieve the effect of reducing frictional static electricity and long-lasting antibacterial and antiviral properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

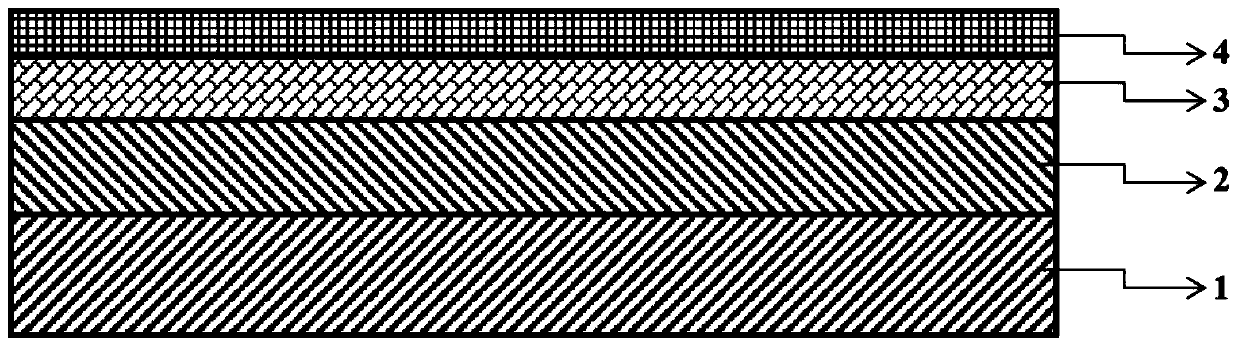

[0074] This embodiment provides a kind of protective fabric, its structural diagram is as follows figure 1 As shown, wherein, 1 is an antistatic base cloth layer, 2 is a waterproof and moisture-permeable layer, 3 is an antibacterial layer, and 4 is an antiviral coating; the specific preparation method is as follows:

[0075] (1) take semi-gloss nylon filament as warp yarn, take semi-gloss nylon filament and conductive yarn 10:1 as weft yarn, weave by water jet loom, obtain antistatic base cloth, conduction in described antistatic base cloth The proportion of yarn is 3.5%;

[0076] (2) Polyurethane adhesive is coated on one side of the antistatic base cloth obtained in step (1), and then compounded with TPU medium permeable film (thickness is 0.08mm), and the compounding roller pressure is 3kg / cm 2 , drying to obtain a fabric containing a waterproof and moisture-permeable layer;

[0077] (3) the lining that step (2) is obtained is placed in the antibacterial finishing liquid ...

Embodiment 2

[0080] This embodiment provides a kind of protective fabric, its structural diagram is as follows figure 1 As shown, wherein, 1 is an antistatic base cloth layer, 2 is a waterproof and moisture-permeable layer, 3 is an antibacterial layer, and 4 is an antiviral coating; the specific preparation method is as follows:

[0081] (1) take polyester filament as warp yarn, take polyester filament and conductive yarn 13:1 as weft yarn, weave by water jet loom, obtain antistatic base cloth, the ratio of conductive yarn in described antistatic base cloth 2.0%;

[0082] (2) Polyurethane adhesive is coated on one side of the antistatic base cloth obtained in step (1), and then compounded with the TPU medium permeable film (thickness is 0.03mm), and the pressure of the compounding roller is 1.5kg / cm 2 , drying to obtain a fabric containing a waterproof and moisture-permeable layer;

[0083] (3) the lining that step (2) is obtained is placed in the antibacterial finishing liquid and carri...

Embodiment 3

[0086] This embodiment provides a kind of protective fabric, its structural diagram is as follows figure 1 As shown, wherein, 1 is an antistatic base cloth layer, 2 is a waterproof and moisture-permeable layer, 3 is an antibacterial layer, and 4 is an antiviral coating; the specific preparation method is as follows:

[0087] (1) Use nylon twisted yarn as warp yarn, nylon twisted yarn and conductive yarn 8:1 as weft yarn, weave by water jet loom to obtain antistatic base cloth, conductive yarn in the antistatic base cloth The ratio of 6.3%;

[0088] (2) One side of the antistatic base cloth obtained in step (1) is coated with polyurethane adhesive, and then compounded with the TPU medium permeable film (thickness is 0.12mm), and the compounding roller pressure is 5kg / cm 2 , drying to obtain a fabric containing a waterproof and moisture-permeable layer;

[0089] (3) the lining that step (2) is obtained is placed in the antibacterial finishing liquid and carries out padding pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com