Material sending module and screen printing machine

A technology of feeding and feeding hoppers, which is applied in the field of feeding modules and screen printing machines, which can solve the problems of manufacturing costs, high maintenance costs in later use, and the inability of fully automatic screen printing machines to be popularized in a large area, reducing manual participation in screen printing To achieve the effect of simple structure, strong competitiveness, and reduced manufacturing and post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

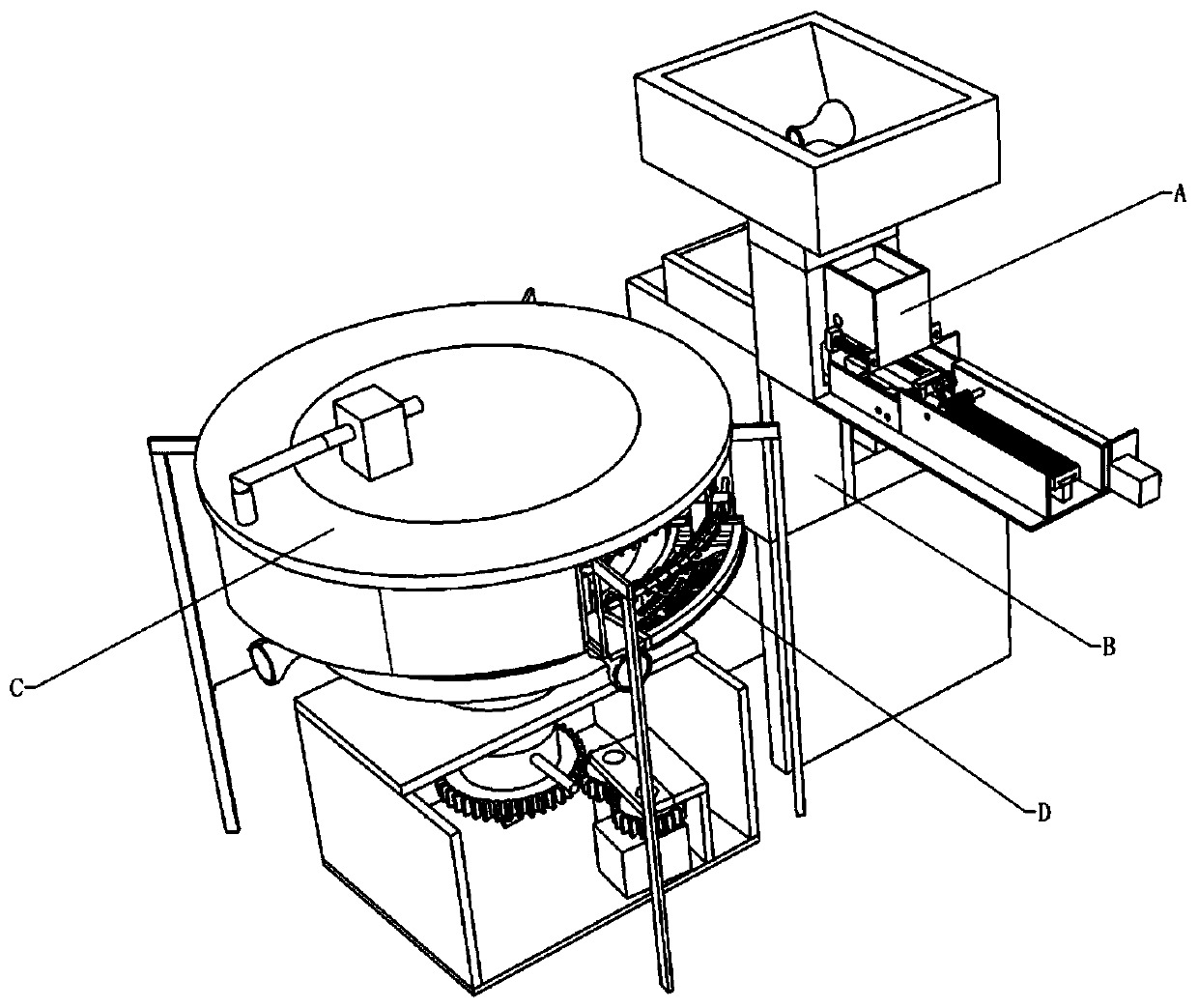

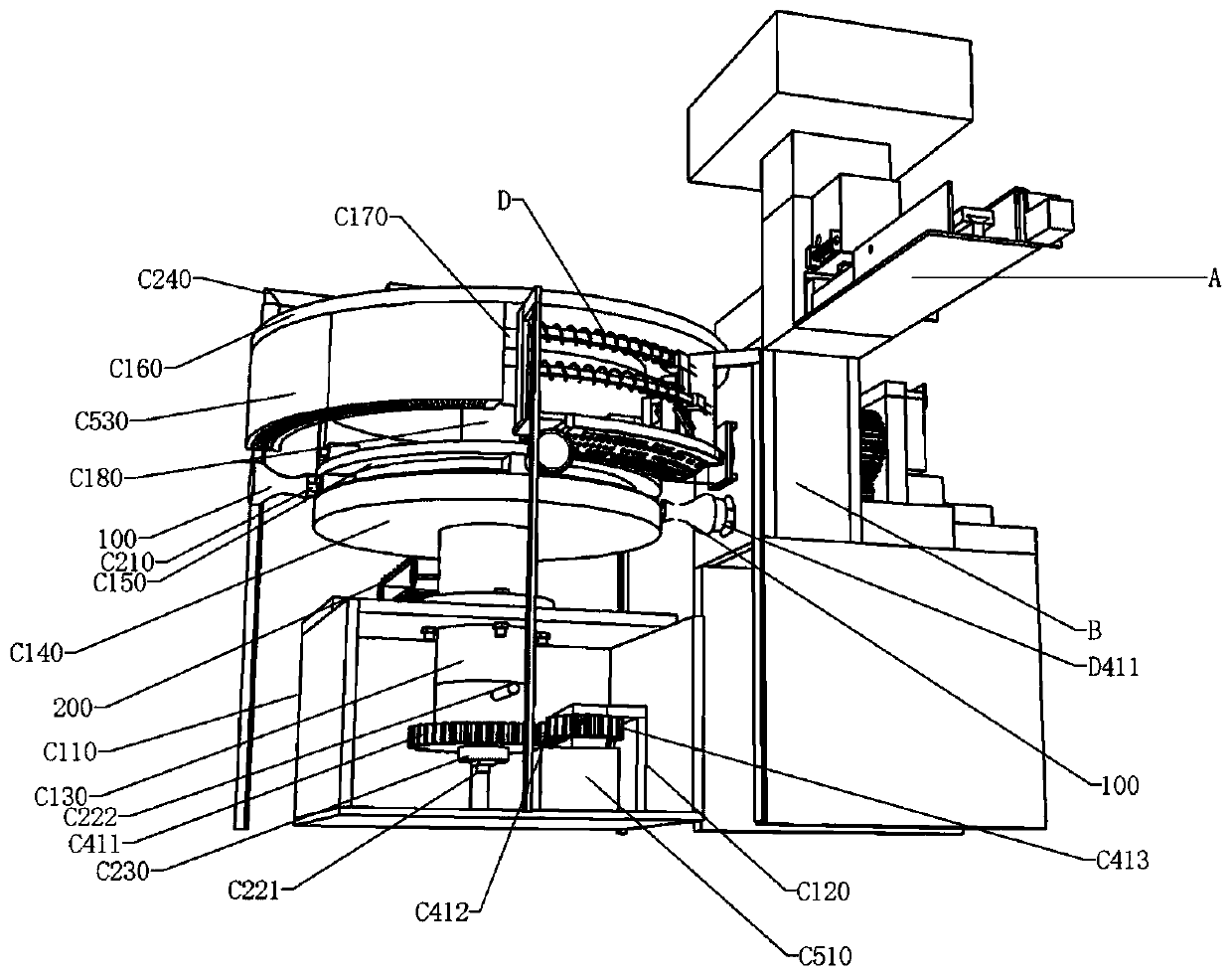

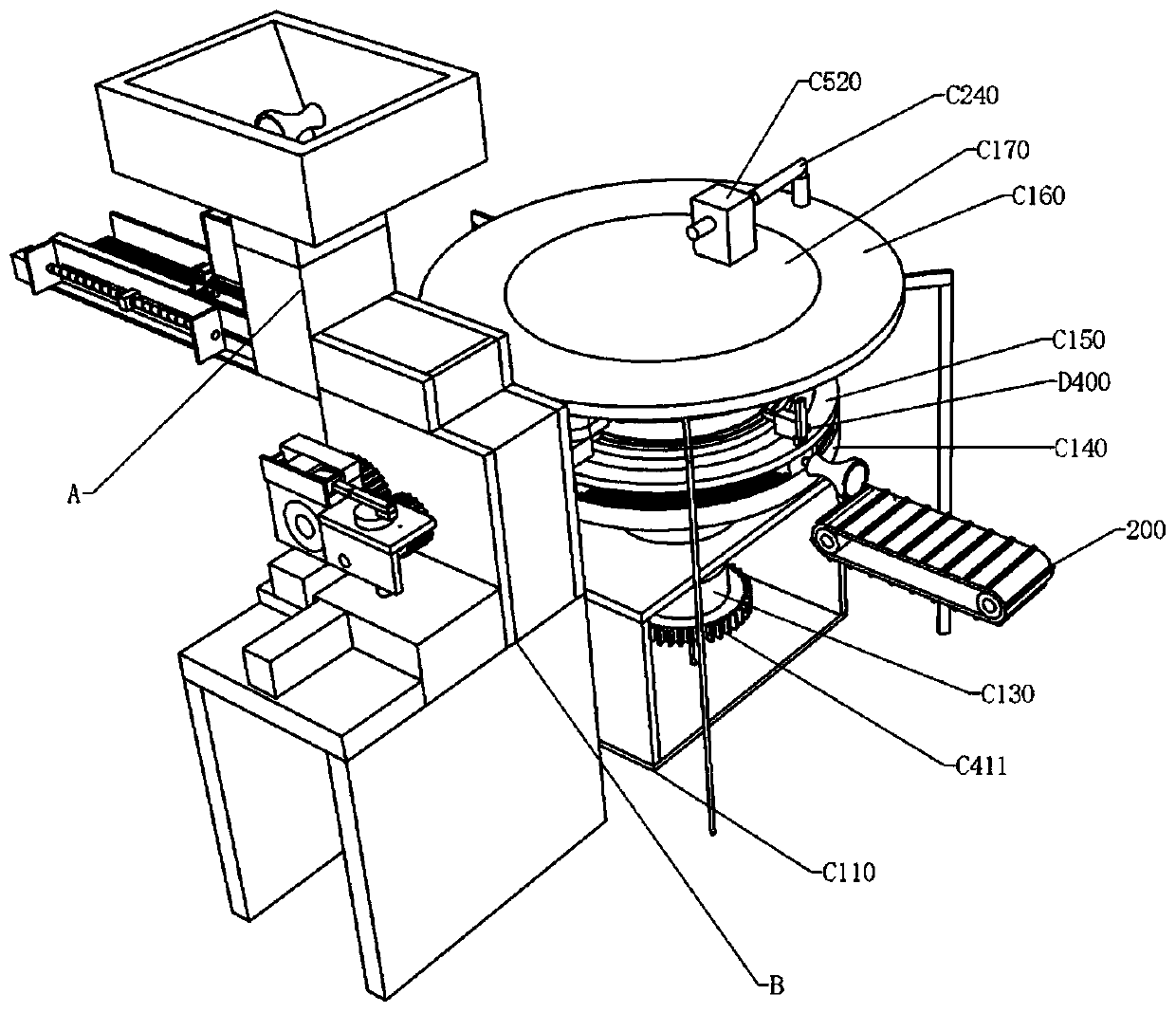

[0024] see Figure 1-Figure 3 , the screen printing machine of this embodiment includes:

[0025] The feeding module A is used to transport the substrates 100 to the feeding module B one by one;

[0026] The feeding module B is used to set the substrates 100 on the conveying shaft of the host one by one to complete the feeding of the substrates one by one;

[0027] The host C is used to drive the substrate to move to different stations, and connect different power according to the station design to complete the loading, printing, drying and unloading of the substrate;

[0028] The printing module D prints the substrate through the first squeegee, the second squeegee and the silk screen;

[0029] The discharge conveyor belt 200 is used to output the printed substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com