Ink jetting distance adjustable type yarn multicolor jet printing machine

An adjustable, inkjet printing machine technology, applied in printing, typewriters, transfer materials, etc., can solve the problem that the inkjet printing needs of diversification of yarn color printing patterns cannot be fully met, the adjustment function of the spacing of interval inkjet printing is limited, The problem of limited applicability of the unit has achieved the effect of compact structure, high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

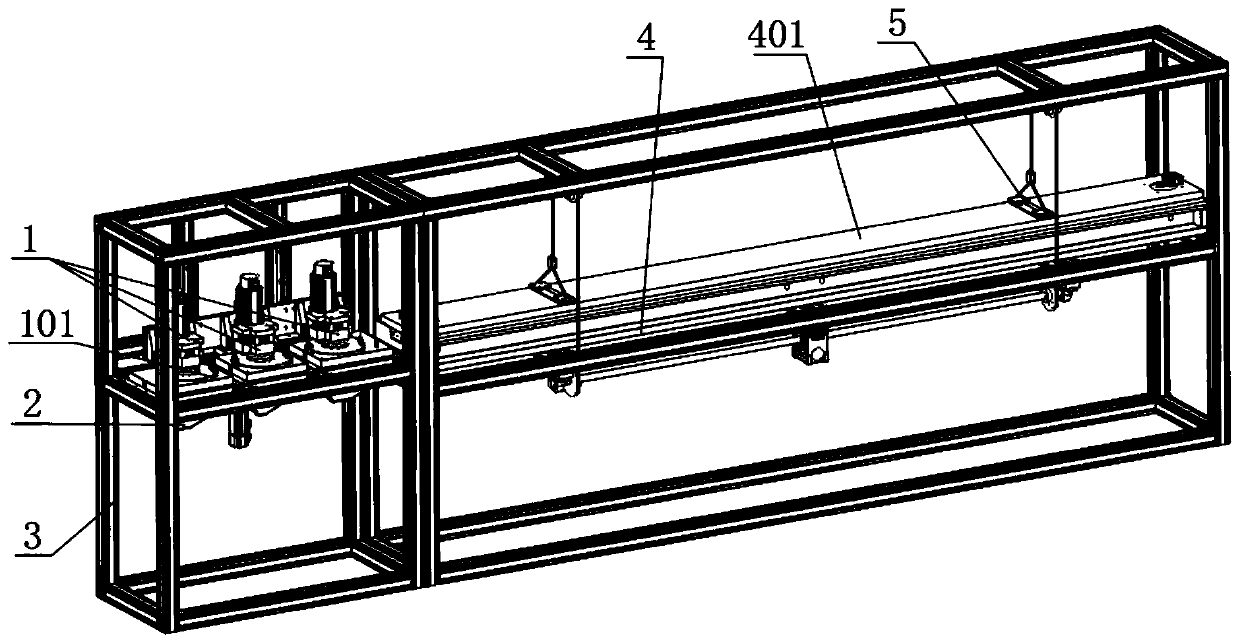

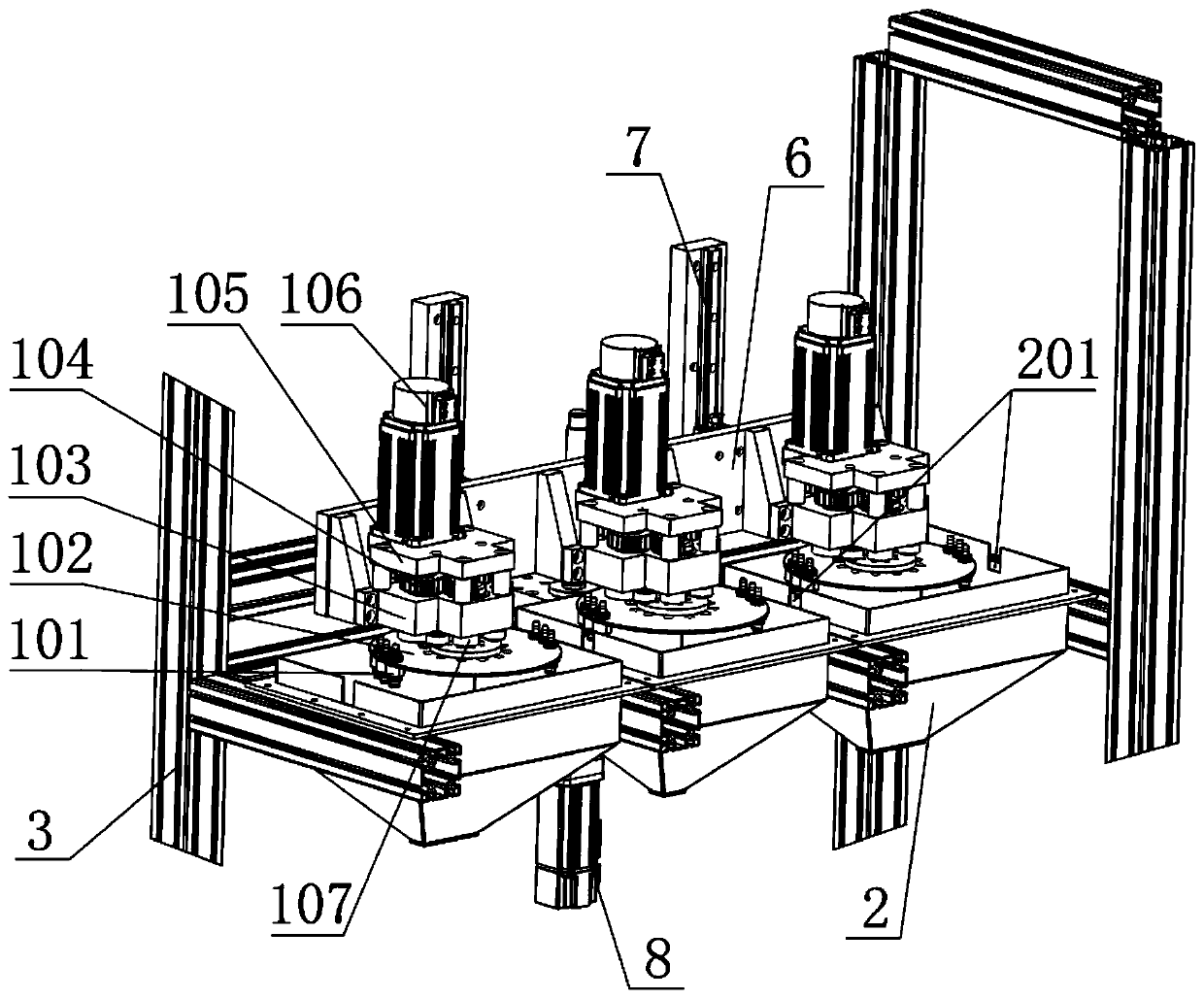

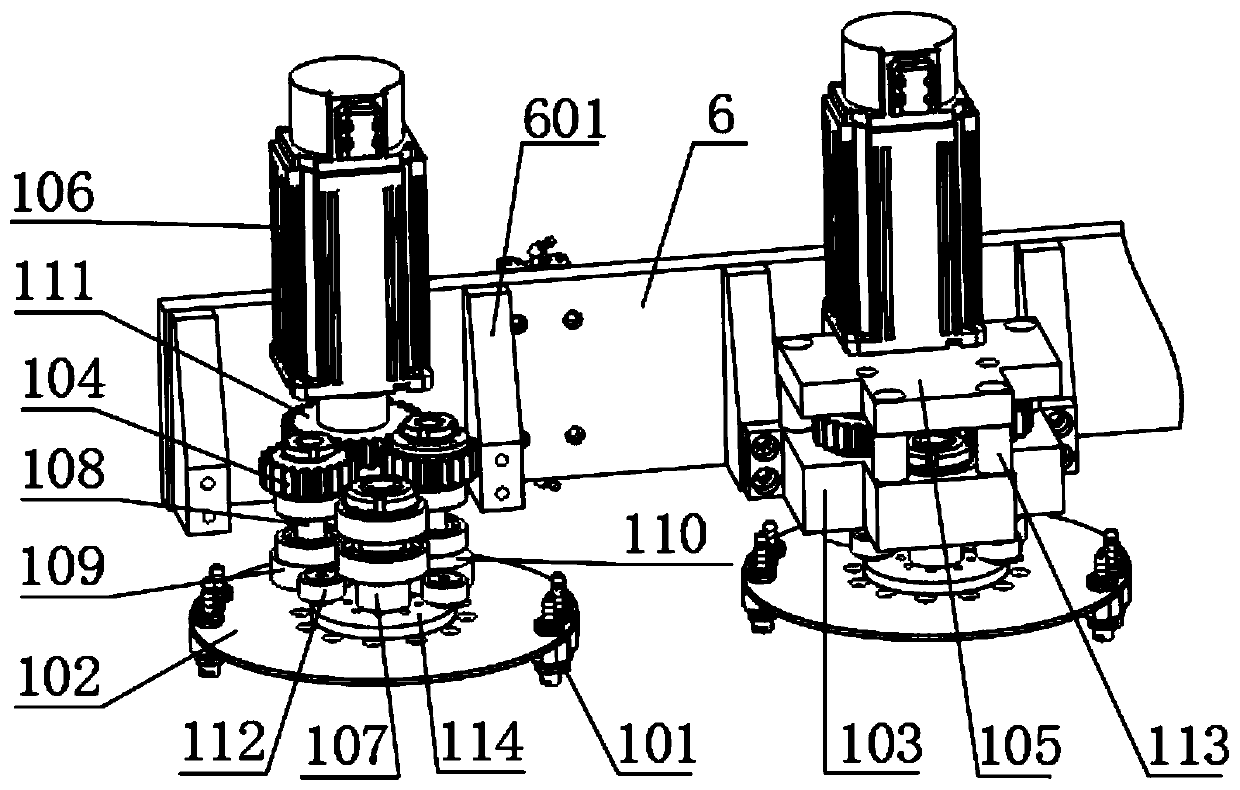

[0027] like figure 1 As shown, the multi-color inkjet printer with adjustable inkjet spacing in this embodiment includes an inkjet mechanism and a yarn fixing mechanism. The structure of the inkjet mechanism is to include a plurality of color components 1 with the same structure. The conveying direction is arranged at intervals in sequence. In this embodiment, three color assemblies 1 are taken as an example. Two groups of nozzles 101 arranged at intervals along the yarn conveying direction are installed under each color assembly 1. The two groups of nozzles 101 are driven by a cam mechanism. Oscillation occurs in the horizontal plane, so that the distance between the nozzles 101 of adjacent color components 1 changes, so as to realize the control of the distance between the colored points on the yarn. Inkjet mechanism and yarn fixation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com