A kind of uv inkjet that can control the end state of ink droplet and its preparation method

A technology of end and state, applied in the field of UV inkjet and its preparation that can control the end state of ink droplets, it can solve the problems of poor compatibility, no ink coming out of the nozzle, easy adsorption on the channel wall, etc., and achieve good compatibility , ink droplet size and speed accurate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

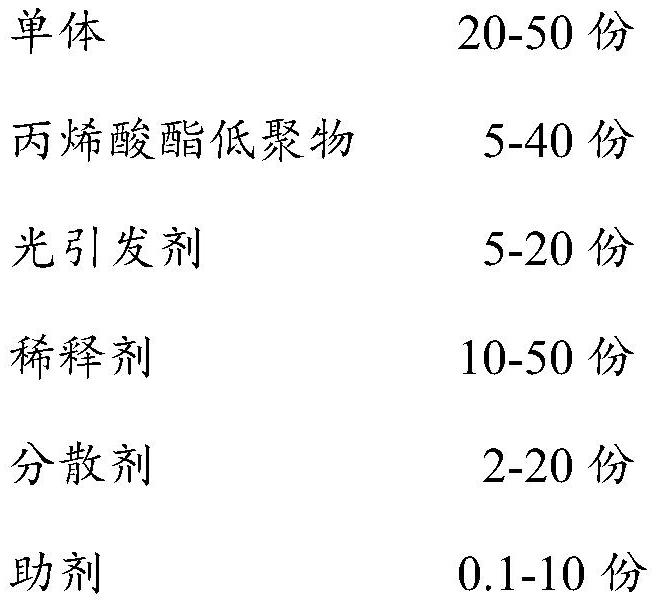

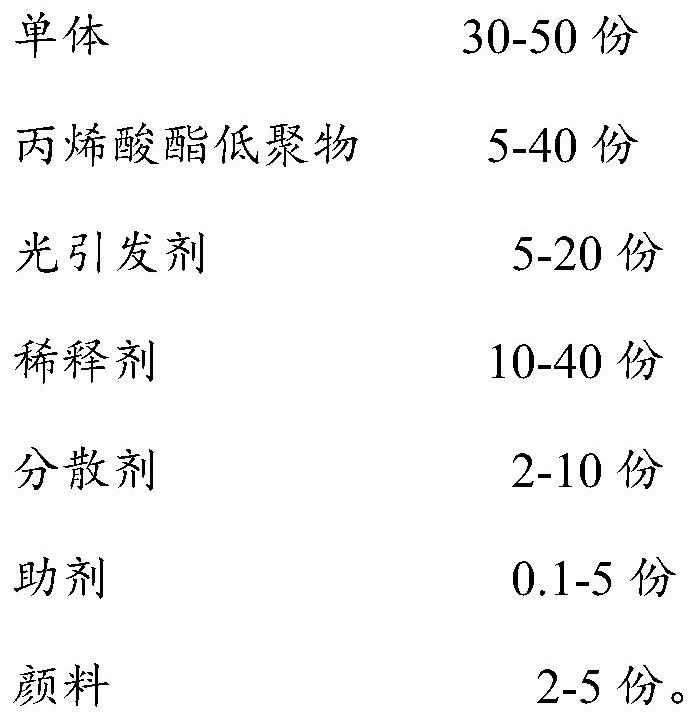

Method used

Image

Examples

Embodiment 1

[0046] The diluent includes 12.2 parts of tetrahydrofurfuryl acrylate and 5.0 parts of N,N-dimethylacrylamide; the monomer includes 10.0 parts of N-acryloylmorpholine, 15.0 parts of cyclotrimethylolpropane formal acrylate, 6.0 parts ethoxylated nonylphenol acrylate, 3.0 parts ethoxylated trimethylolpropane triacrylate, 10.0 parts o-phenylphenoxyethyl acrylate; acrylate oligomers including 15.0 parts polyurethane acrylate and 5.0 parts cyclo Oxyacrylates; photoinitiators include 7.0 parts 2,4,6-trimethylbenzoyldiphenylphosphine oxide, 3.0 parts 2,4-diethylthiazolone; additives include 0.5 parts BYK-337 wetting Agent, 0.8 parts of p-hydroxyanisole stabilizer; and 2.5 parts of dispersant Solsperse24000 were stirred until completely dissolved, the stirring speed was 1000rpm, and the stirring time was 4hr to obtain a pre-solution;

[0047] Mix and stir the aforementioned pre-solution with 5.0 parts of red pigment PR-122 until the pigment is completely wetted, the stirring speed is ...

Embodiment 2-6

[0049] The formula of embodiment 2-6 is shown in table 1, and preparation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com