Lost foam casting method of engine gear chamber

A technology of lost foam casting and lost foam, which is applied in the direction of casting molding equipment, molds, mold components, etc. It can solve the problems of casting pores and structure, difficulty in mass production, poor air permeability of clay sand, etc., and achieve simplification. Production process, reduce labor intensity and technical difficulty, reduce the effect of raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

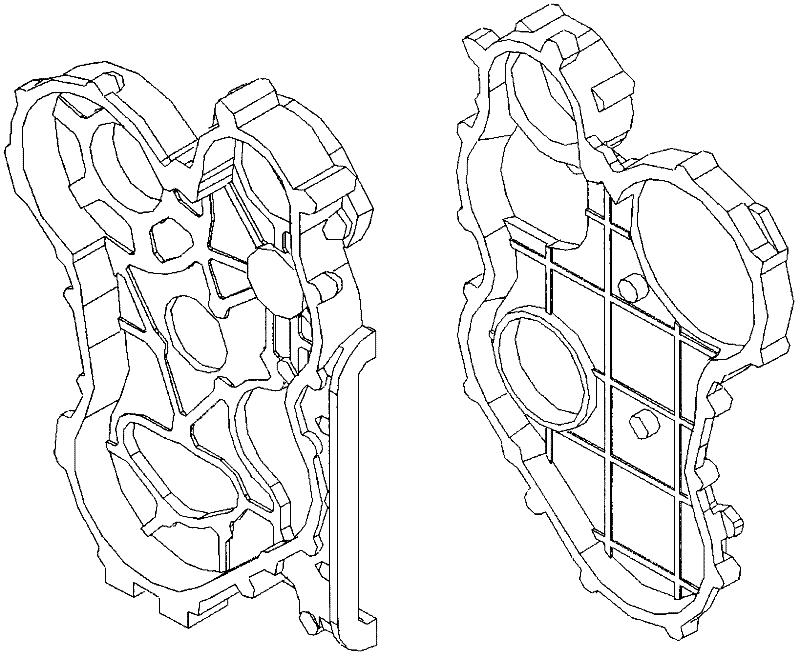

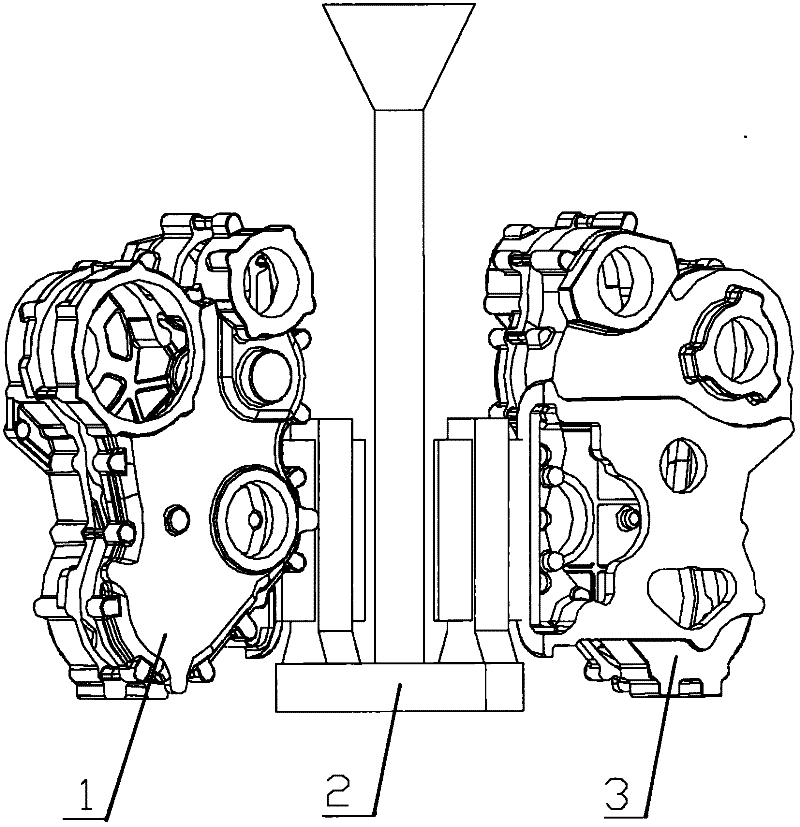

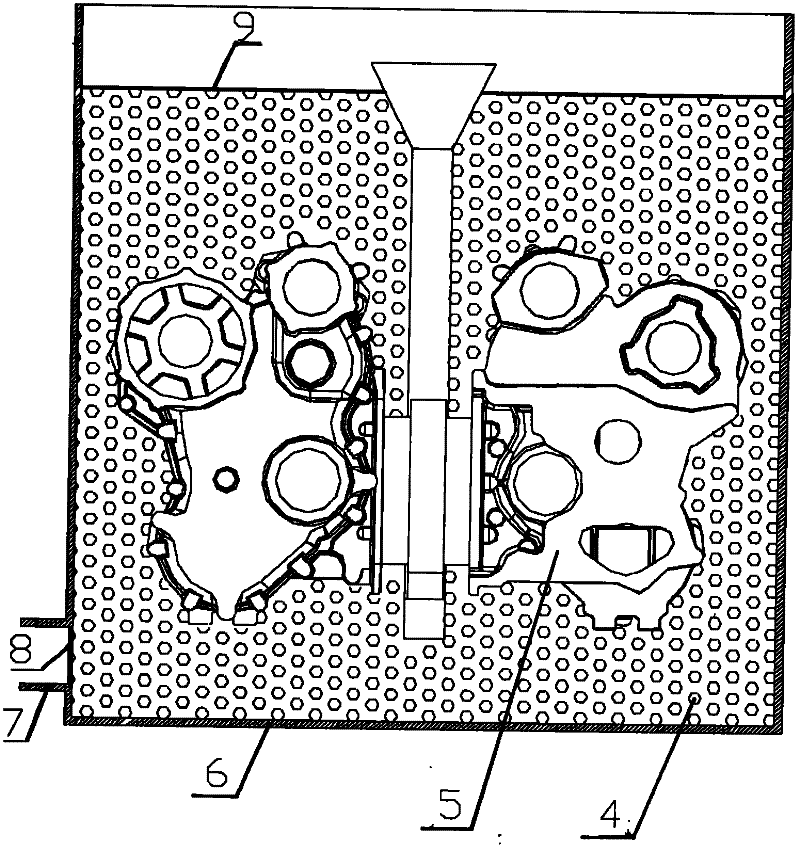

[0024] Such as figure 1 , figure 2 , image 3 Shown, a kind of lost foam casting method of engine gear chamber, process method is as follows,

[0025] ①. According to product drawings and casting requirements, use 3D software to design a model for manufacturing lost foam dies, and manufacture corresponding molds;

[0026] ②. Inject expandable mold-making beads into the mold manufactured in step ①, produce each mold after heating and cooling, and send it to a drying room with a temperature of 40 ° C to 50 ° C for drying treatment;

[0027] ③. Bond the dried molds in step ② into a whole as required to form the lost foam mold 3 of the timing gear chamber and the lost foam mold 1 of the gear chamber cover, and the lost foam mold of the timing gear chamber 3 and the lost foam mold piece 1 of the gear chamber cover are bonded to the casting system 2 to obtain the lost foam model 5;

[0028] ④. Dip-coat the special paint on the surface of the lost foam model 5, so that the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com