Rolling equipment for road construction

A technology for road construction and equipment, applied in the field of rolling equipment for road construction, can solve the problems such as the inability of paving operation and compaction operation to be carried out simultaneously, uneven paving of asphalt paving equipment, low work efficiency, etc. , The effect of improving asphalt firmness and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

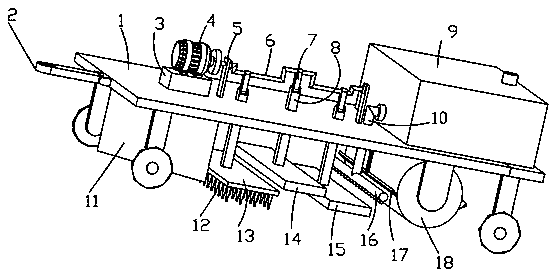

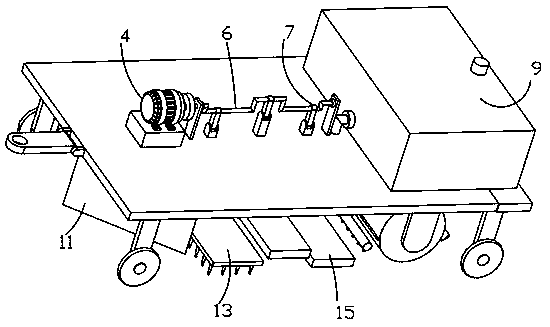

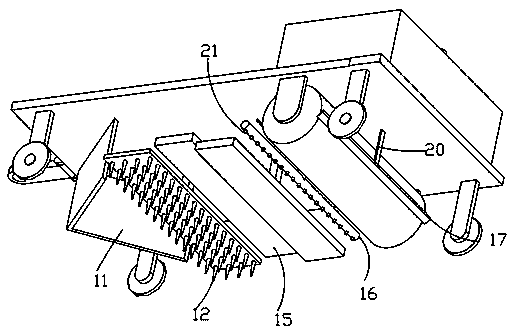

[0032] Such as Figure 1-4 The rolling equipment for road construction shown includes a vehicle board 1 and rollers 23. The left end of the top of the vehicle board 1 is fixedly connected with a traction ring 2, and the bottom of the vehicle board 1 is symmetrically fixedly connected with a second straight board 22, and the second straight board 22 passes through The fixedly connected bearing is rotatably connected with a roller 23, and the left end of the bottom of the car plate 1 is provided with an asphalt paving structure, which is an umbrella-shaped push plate 11, and the bottom of the umbrella-shaped push plate 11 is higher than the height of the bottom of the pressure roller 18. The flat structure is an umbrella-shaped push plate, and the movable umbrella-shaped push plate is convenient to push the asphalt on the road surface, and can pave the asphalt with a slightly higher accumulation to a slightly lower plane, so that the originally uneven asphalt surface tends to be ...

Embodiment 2

[0034] Such as Figure 1-4As shown, a rolling equipment for road construction includes a vehicle board 1 and rollers 23, the top left end of the vehicle board 1 is fixedly connected with a traction ring 2, and the bottom of the vehicle board 1 is symmetrically fixedly connected with a second straight board 22, and the second straight board 22 passes The fixedly connected bearing is rotatably connected with a roller 23, and the left end of the bottom of the car plate 1 is provided with an asphalt paving structure, which is an umbrella-shaped push plate 11, and the bottom of the umbrella-shaped push plate 11 is higher than the height of the bottom of the pressure roller 18, and the asphalt is paved. The right end of the structure is provided with a tamping structure, the tamping structure includes a rotating motor 4, a crankshaft 6, a rotating plate 7, a slide plate 8, a mounting plate 13, a first tamping plate 12 and a second tamping plate 13, and the rotating motor 4 is fixed b...

Embodiment 3

[0036] Such as Figure 1-4 As shown, a rolling equipment for road construction includes a vehicle board 1 and rollers 23, the top left end of the vehicle board 1 is fixedly connected with a traction ring 2, and the bottom of the vehicle board 1 is symmetrically fixedly connected with a second straight board 22, and the second straight board 22 passes The fixedly connected bearing is rotatably connected with a roller 23, and the left end of the bottom of the car plate 1 is provided with an asphalt paving structure, which is an umbrella-shaped push plate 11, and the bottom of the umbrella-shaped push plate 11 is higher than the height of the bottom of the pressure roller 18, and the asphalt is paved. The right end of the structure is provided with a compaction structure, the right end of the compaction structure is provided with a road surface humidification structure, the right end of the humidification structure is provided with a compaction structure, and the compaction struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com