High-strength bolt assembly for connecting box-shaped beams and columns

A technology of high-strength bolts and high-strength bolts, applied in the direction of connecting components, bolts, threaded fasteners, etc., can solve the problems of difficult quality assurance, large workload and high cost, and achieve quality control, reduce work strength, and durability. and safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

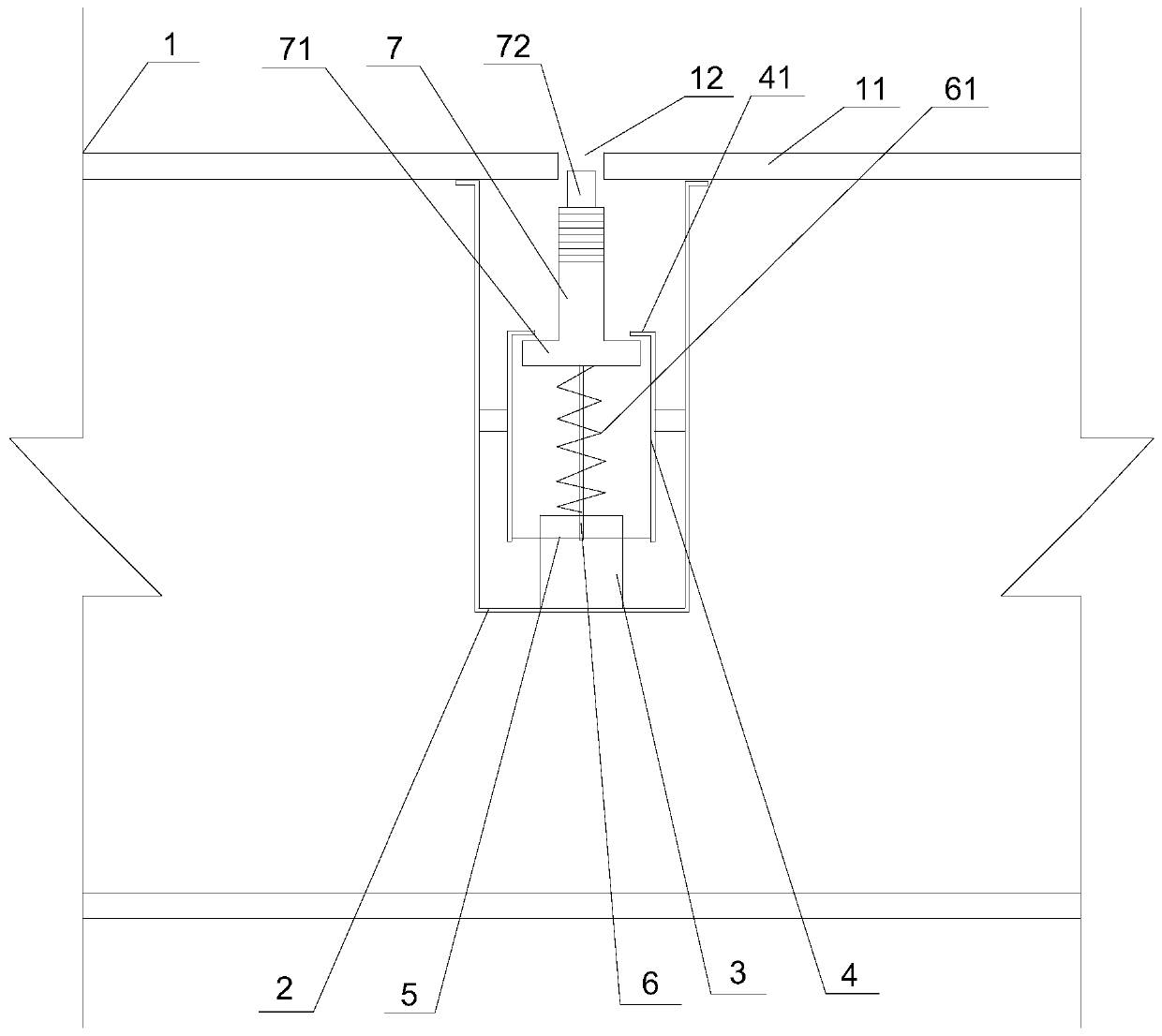

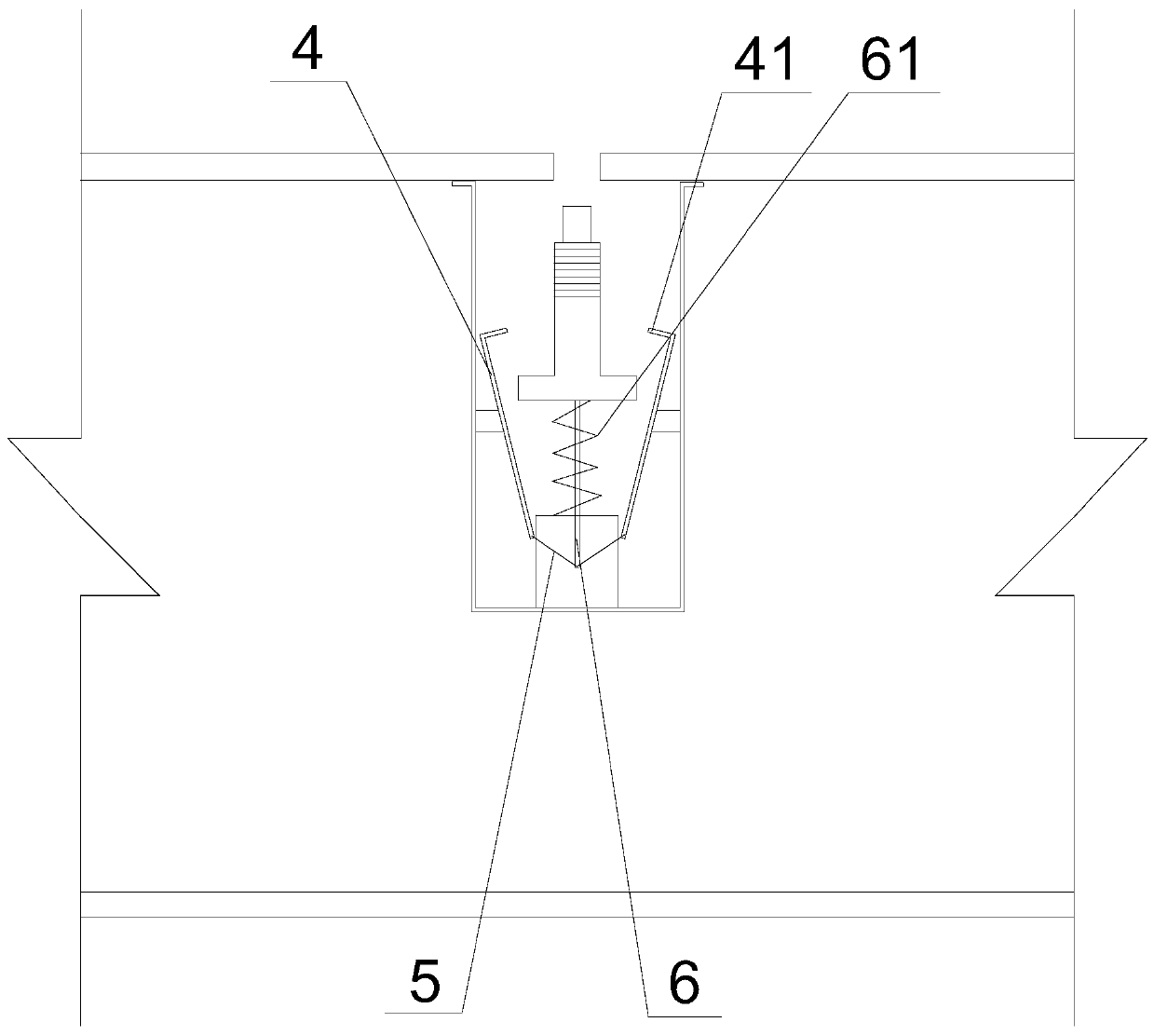

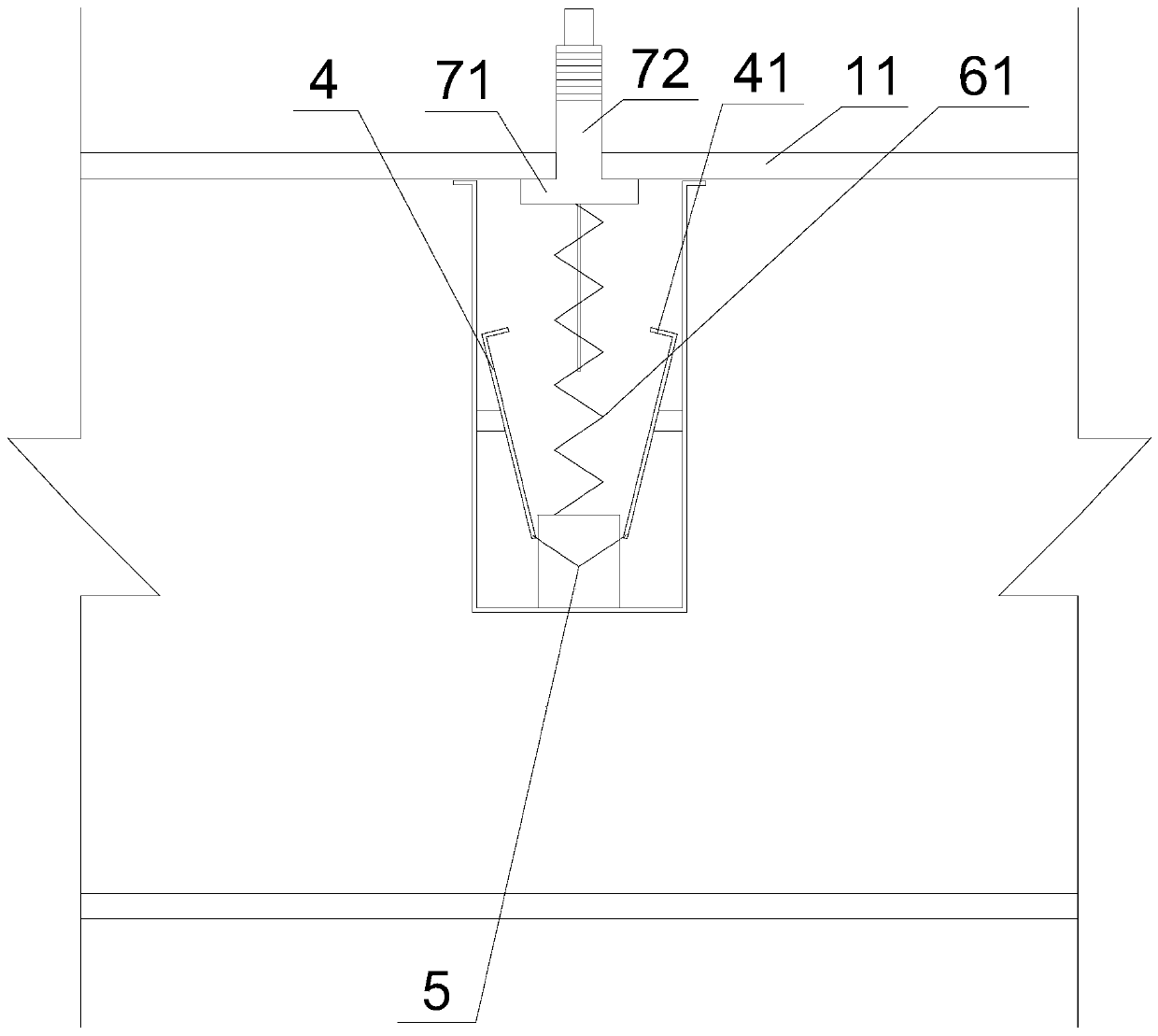

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1 to Figure 4 , the figure shows a high-strength bolt assembly for box beam-column connection of the present invention, including:

[0021] A box-shaped member 1, the top of the box-shaped member 1 is provided with a top plate 11, a through hole 12 is opened on the top plate 11, and an outer cylinder 2 is installed on the lower surface of the top plate 11;

[0022] An inner cylinder 3, the inner cylinder 3 is installed on the bottom of the outer cylinder 2;

[0023] Two fixing parts 4 symmetrically installed on the inner wall of the outer cylinder 2, the top of each fixing part 4 extends radially inwards with a limiting plate 41, the bottoms of the two fixing parts 4 are connected by a steel wire 5, the left and right ends of the steel wire 5 Pass through the inner wall of the inner cylinder 3;

[0024] A support rod 6, the bottom end of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com