Assembly type light bamboo and wood fiber board partition wall system

A bamboo-wood fiber and assembly technology, applied to walls, building materials, building components, etc., can solve problems that affect human health, pollute indoor air, and easily contain harmful components, etc., achieve good bending performance, improve utilization rate, reduce The effect of load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

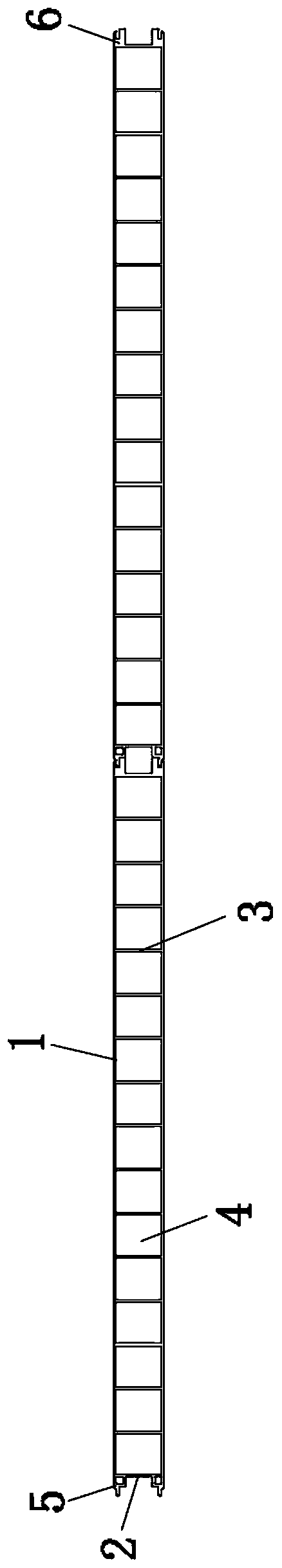

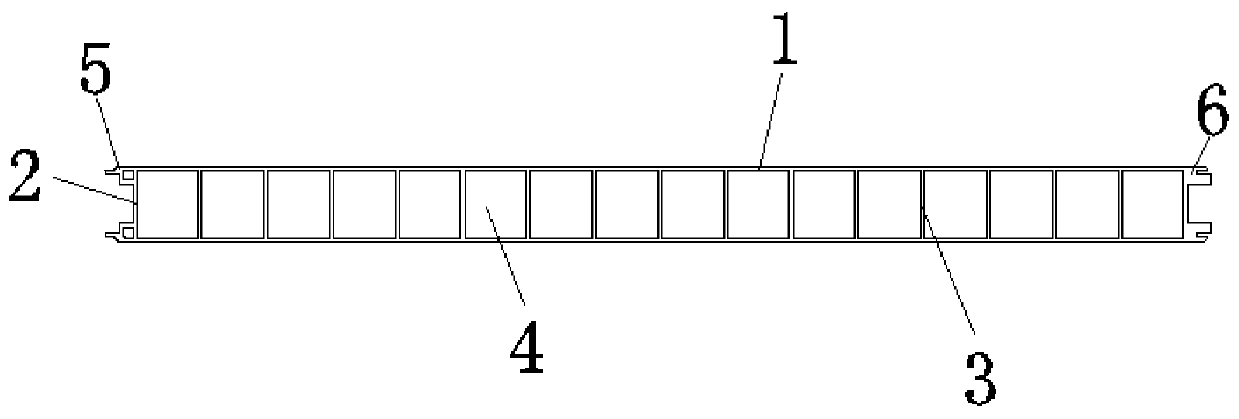

[0032] see Figure 1 to Figure 2 , Figure 5 , the figure shows an assembled lightweight bamboo-wood fiberboard partition wall system provided by Embodiment 1 of the present invention, which includes: at least two connected bamboo-wood fiberboards, the bamboo-wood fiberboards include two panels 1 arranged in parallel, The side plates 2 arranged on both sides of the panel 1 and the partitions 3 arranged between the panels 1, the partitions 3 are arranged at intervals to form uniformly distributed cavity grids 4; the two ends of the bamboo fiberboard are respectively provided with sub-buttons 5 With the female buckle 6, two adjacent bamboo fiberboards are connected through the sub-button 5 and the female buckle 6. Wherein, the child buckle 5 is symmetrically arranged on the same side of the two panels 1 , and the female button 6 is symmetrically arranged on the other side of the two panels 1 .

[0033] An assembled lightweight bamboo-wood fiberboard partition wall system provi...

Embodiment 2

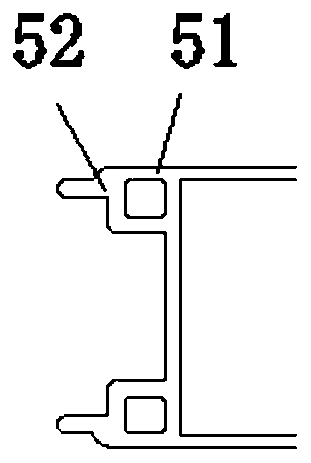

[0041] see Figure 3 to Figure 5 , the figure shows an assembled lightweight bamboo-wood fiberboard partition wall system provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The child buckle 5 includes a connecting seat 51 and an insertion strip 52 arranged on the outside of the connecting seat 51; the side shape of the connecting seat 51 is "mouth"; the female button 6 includes a socket 61 and a slot 62 arranged in the socket 61; Strip 52 mates with slot 62 . Through the setting of the above structure, the inserting strip 52 is installed in the slot 62, so that two pieces of bamboo fiber boards can be quickly installed and the construction efficiency can be improved.

Embodiment 3

[0043] see figure 2 , Figure 6 , the figure shows an assembled lightweight bamboo-wood fiberboard partition wall system provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The insertion strip 52 and the slot 62 are all arranged along the height direction of the bamboo fiberboard; the outer sides of the connecting seat 51 and the socket 61 are flush with the panel 1 . Through the setting of the above structure, the sides of the two bamboo fiberboards can be completely connected, and after the connection, they are flush with the panel 1, and there will be no protrusion or depression, which improves the overall aesthetics and further improves the Connection strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com